When working with complex machinery, understanding its individual components is essential for proper operation and maintenance. Knowing how each element functions and fits together ensures efficiency and longevity, while also making repairs and replacements easier. In this guide, we will break down the main elements of a popular cutting machine, providing you with the knowledge needed to keep it running smoothly.

Identifying the Core Elements

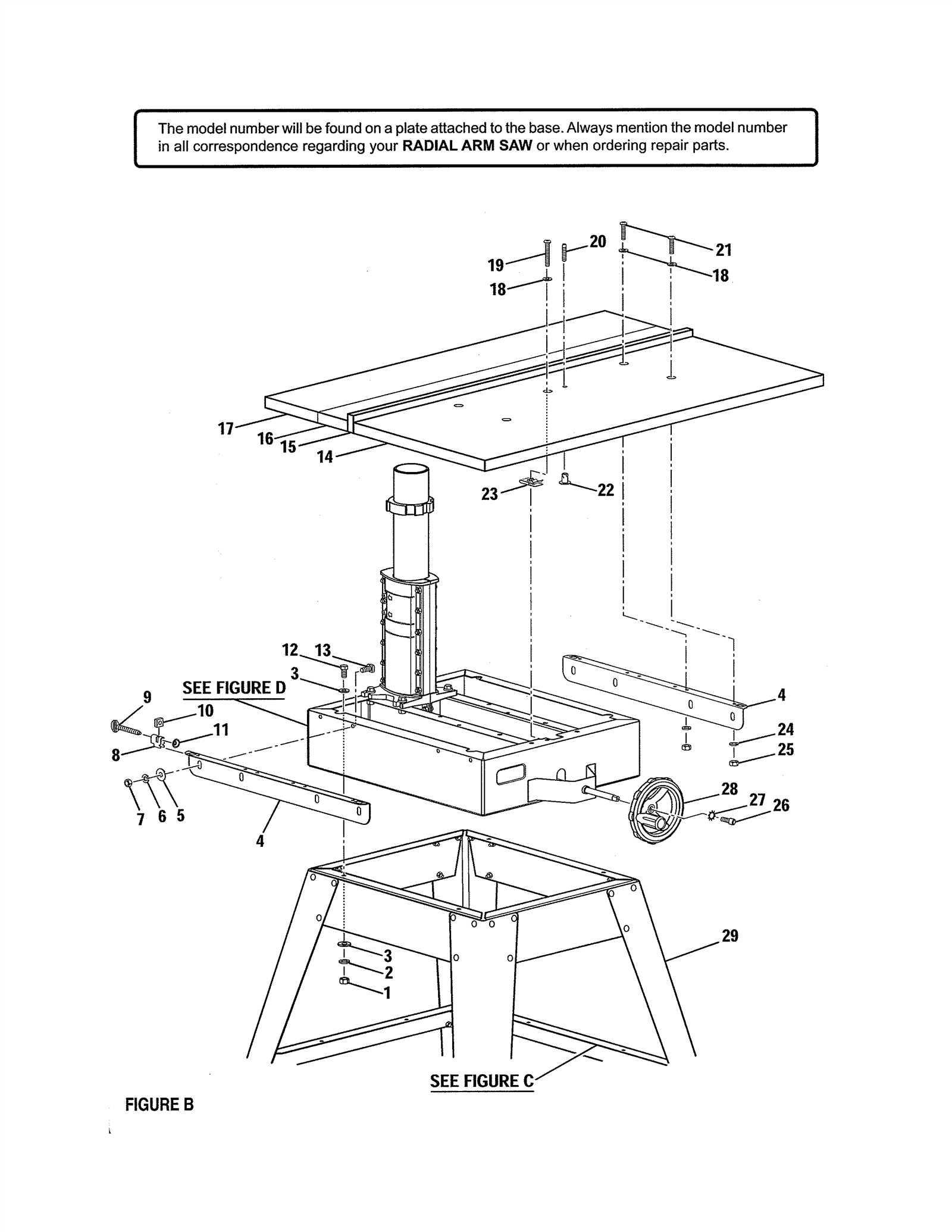

Every tool is made up of various parts that perform specific functions. The main structure typically includes a motor, guide system, and cutting mechanism. These components work together to provide the precision and power necessary for clean cuts. Understanding their placement and connection will help you troubleshoot or replace any malfunctioning sections.

Motor and Power Supply

The heart of the tool is the motor, responsible for driving the system. It converts electrical energy into mechanical power to operate the machine. Regular maintenance of the motor and ensuring the power supply is stable can prevent many common issues.

Guide System and Track

The guide system directs the movement of the cutting tool. It is essential to keep the track aligned and free of debris to ensure smooth operation. Misalignment can cause inaccurate cuts and unnecessary wear on other components.

Troubleshooting and Repairs

Sometimes, even the most well-maintained machine will experience issues. Common problems include loss of power, uneven cutting, or difficulty adjusting the cutting head. Understanding the layout of your tool helps in identifying which section may need attention.

- Power loss: Check the motor, power switch, and electrical connections for issues.

- Uneven cuts: Inspect the guide system for misalignment or wear on the cutting edge.

- Stiff adjustments: Ensure all moving parts are lubricated and free from obstruction.

Replacing Damaged Components

When it’s time to replace worn-out parts, always use the correct replacement parts designed for your specific tool. Using non-compatible pieces may lead to further damage or inefficient performance. Always refer to the user manual or a professional for guidance.

Understanding the Key Elements of Your Cutting Tool

Every complex cutting machine consists of various components that must work together to ensure proper functioning. Identifying and understanding the roles of these elements is crucial for effective operation and maintenance. Whether you’re performing routine checks or dealing with issues, knowing how each part contributes to the tool’s performance is essential.

One of the first steps in managing your tool is learning how to identify the essential elements, such as the motor, guide system, and the cutting head. Each part has a specific role, whether it’s providing power, maintaining precision, or adjusting the cut. Understanding their layout allows you to operate the machine more efficiently and address any concerns that may arise.

Common Issues with Cutting Machines

While these tools are designed to last, issues can occur due to wear and tear. Some of the most common problems include power loss, misalignment of the cutting track, and issues with the cutting mechanism. A loss of power may stem from a faulty motor or power connection, while misalignment can affect the accuracy of the cuts. Keeping an eye on these issues can prevent further damage and ensure better results.

Troubleshooting and Replacing Components

When something goes wrong, understanding where the issue lies is key. To troubleshoot effectively, check the power system, alignment, and movement of parts. If adjustments or repairs are necessary, follow proper procedures to replace damaged elements. Regular maintenance is essential to keep the tool in optimal condition, extending its lifespan and maintaining peak performance.