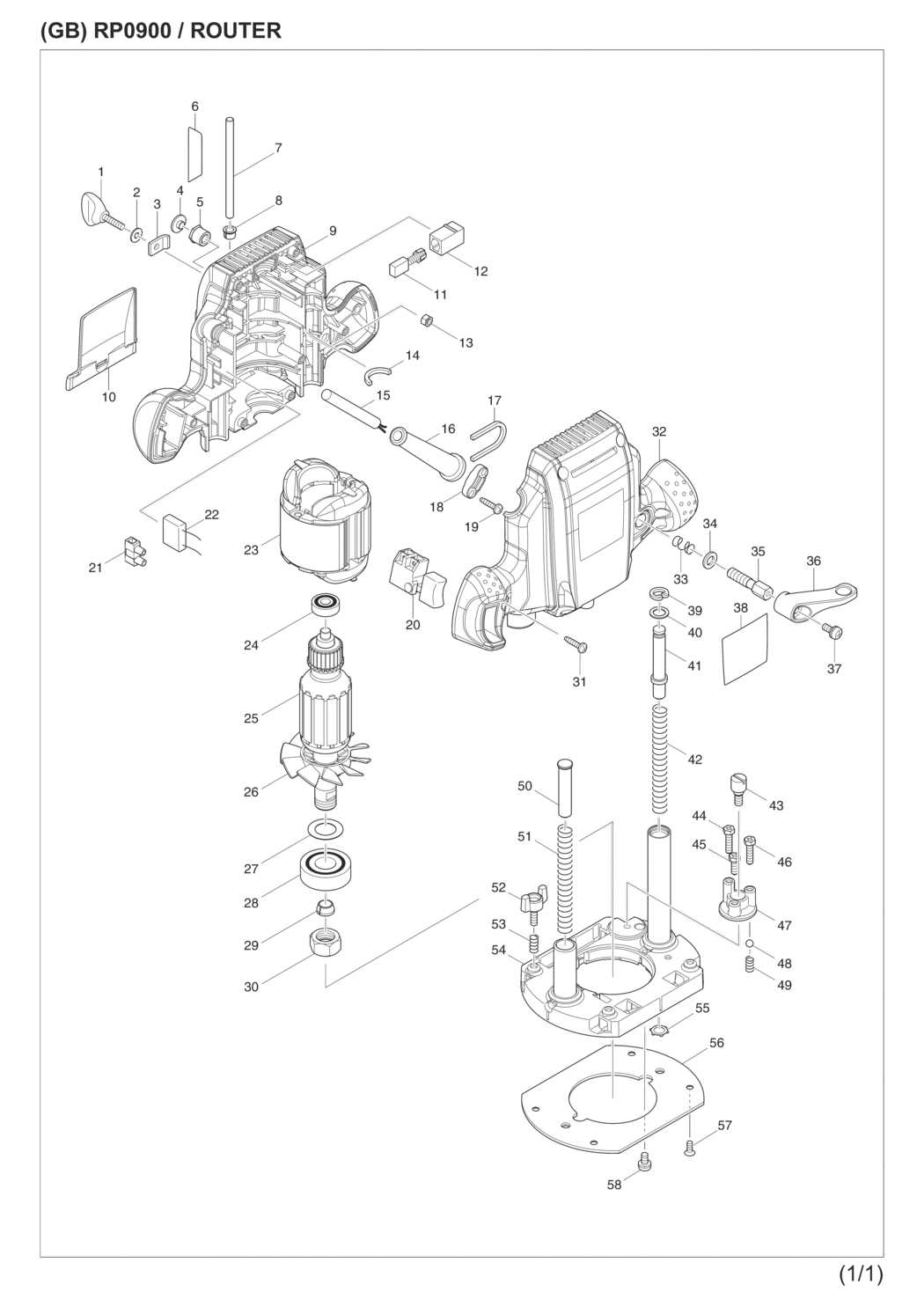

When working with precision tools, it is essential to have a clear understanding of each individual component. Knowing the function and location of each piece allows for efficient use and proper care. Proper maintenance ensures longevity and peak performance, reducing the risk of damage or malfunction.

Identifying and understanding the various parts of your equipment can seem overwhelming at first, but with the right guidance, it becomes a straightforward task. Recognizing the role of each element will help you troubleshoot any issues and perform necessary repairs with confidence.

Whether you’re a professional or a hobbyist, maintaining your tools through regular checks and replacements can significantly improve their reliability. This guide will provide the necessary insights to ensure your tool remains in top working condition for years to come.

Understanding Power Tool Components

Every precision tool consists of various elements that work together to perform complex tasks. Recognizing how each part contributes to the overall function is crucial for both effective use and maintenance. Whether you’re looking to repair or upgrade your equipment, having a clear understanding of these components can make the process much easier.

Main Functionality of Key Components

At the heart of any power tool are the key components that drive its primary functions. These may include the motor, the housing, the power switch, and the adjustment mechanisms. Each of these pieces works in tandem to allow for smooth operation, enabling the tool to complete its intended tasks with precision. Understanding how they fit together is fundamental for anyone looking to perform repairs or improvements.

Common Issues and Troubleshooting

Familiarity with the individual parts also makes it easier to identify common issues. From power failures to malfunctioning controls, knowing what each component does can help pinpoint the problem more quickly. Troubleshooting becomes more efficient when you are aware of the possible causes linked to specific elements, making maintenance and repairs less daunting.

How to Identify Tool Components

Recognizing the different elements of a tool is essential for effective use and maintenance. Identifying each component allows you to better understand the functionality and troubleshooting process, ensuring the equipment performs optimally. Knowing the key features also helps when it comes time for repairs or replacements.

Steps to Identify Key Components

There are several approaches you can take to accurately identify the various parts of your tool:

- Consult the user manual for a detailed list of components and their functions.

- Examine the tool visually, noting any labels or markings that indicate part names.

- Use online resources or reference guides to cross-check component images and terminology.

- Look for specific features such as the power switch, motor housing, or adjustment knobs that distinguish key parts.

Common Elements to Look For

Most tools consist of a few core components that are essential for operation. Some of the most common ones include:

- Motor Housing: The casing that holds the motor and related electrical components.

- Power Switch: The mechanism used to turn the tool on and off.

- Adjustment Mechanisms: Knobs or levers used to control settings like speed or depth.

- Base or Footplate: The stable platform that supports the tool during use.

Maintaining Your Power Tool

Proper care and upkeep of your equipment are essential for ensuring long-lasting performance and preventing common issues. Regular maintenance helps keep all elements in working order, reduces wear and tear, and improves overall efficiency. By following simple steps, you can ensure your tool remains reliable and effective for years to come.

Routine Checks and Cleaning

One of the most important tasks in maintaining your tool is performing routine inspections and cleaning. Over time, dust, debris, and other particles can accumulate inside the housing or around moving parts, leading to decreased performance or damage. Here’s how to keep everything running smoothly:

- Unplug the tool before cleaning to avoid any accidents.

- Use a soft brush or compressed air to remove dust and debris from vents and crevices.

- Clean the exterior with a damp cloth to remove dirt and grime.

- Check for any signs of wear or damage on the exterior and interior components.

Lubrication and Part Replacement

Lubricating the moving components of your tool ensures that they continue to operate smoothly without unnecessary friction. Over time, parts may wear down or become damaged, requiring replacement. To keep your tool in optimal condition, follow these steps:

- Apply lubricant to the moving parts according to the manufacturer’s guidelines.

- Inspect essential components for wear and replace them when necessary.

- Ensure that all screws and fasteners are tightened properly to avoid parts loosening during operation.