Proper maintenance of outdoor machinery is crucial for ensuring efficient performance during the colder months. Whether you are dealing with a powerful machine for clearing pathways or another tool, understanding the structure and functionality of its components can save time and effort. With the right knowledge, diagnosing issues and carrying out repairs becomes a much simpler task.

Familiarizing yourself with the individual parts of your equipment helps you identify potential problems early and avoid costly repairs. Each component plays a specific role in the overall operation, and knowing how they fit together makes troubleshooting far easier. Being able to recognize common issues also prevents unnecessary downtime when conditions outside require immediate action.

Knowing the layout and functionality of each part can make all the difference when trying to restore equipment to its optimal condition. A clear guide to the structure of your machine will help you understand which elements may need attention, ultimately keeping your equipment in top shape throughout the season.

Understanding Craftsman Snow Blower Components

Each machine designed for winter maintenance consists of several critical elements, each playing a vital role in its overall functionality. Knowing how these individual components work together can help you better manage repairs, maintenance, and even performance optimization. Recognizing the key parts and their positions allows for smoother troubleshooting and repairs when problems arise.

Main Mechanisms of Operation

At the heart of every outdoor equipment machine is the system responsible for propulsion and clearing. Understanding the movement of these critical mechanisms ensures that you can effectively handle issues related to power transfer and material handling. A breakdown of these core mechanisms can help identify where malfunctions are occurring and which parts are responsible.

Supporting and Auxiliary Elements

Along with the main operational components, there are several auxiliary systems that provide support and enhance functionality. These include safety features, control systems, and parts that regulate the performance of the machine in various conditions. Familiarity with these additional components can aid in preventing unnecessary wear and improving the longevity of the equipment.

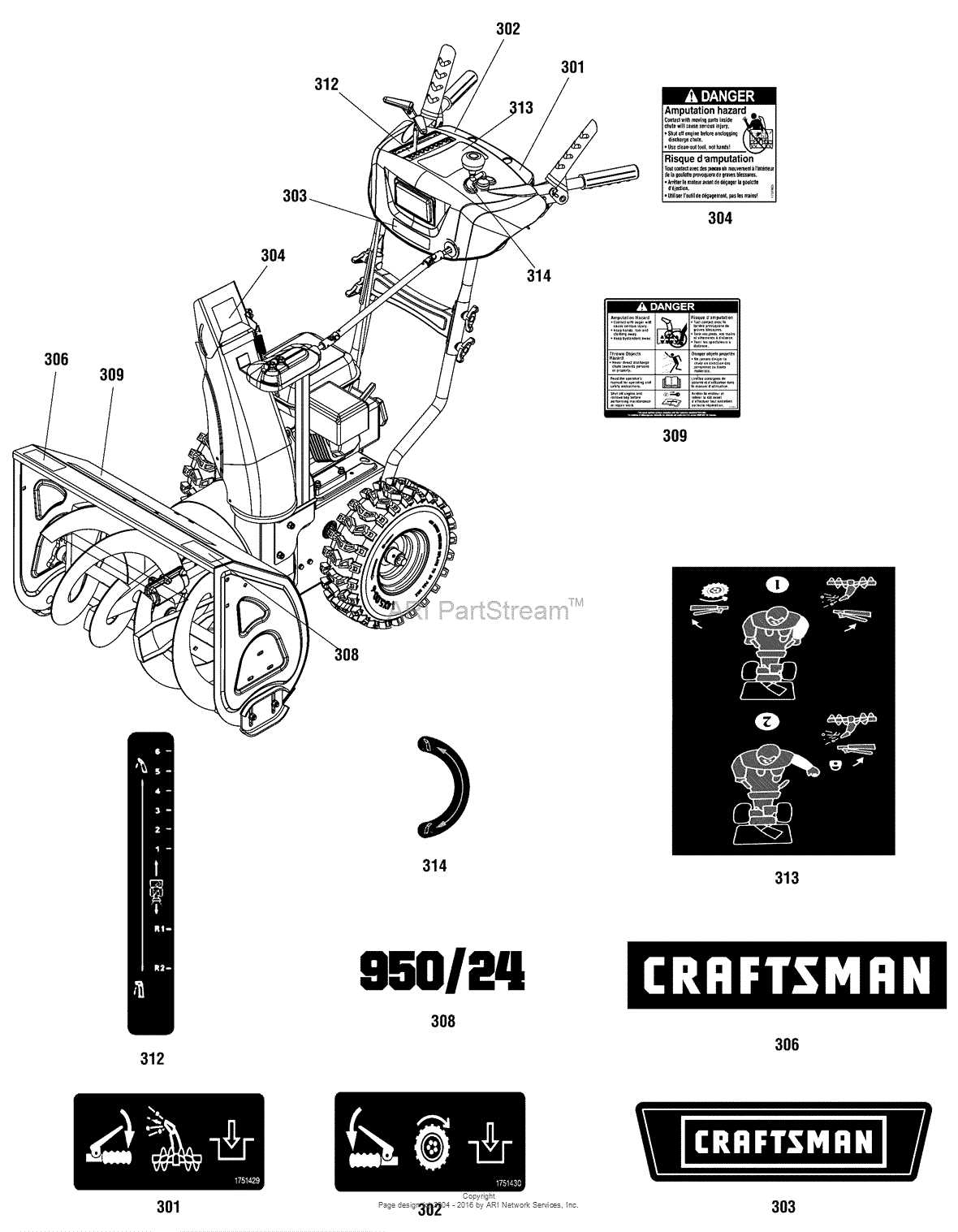

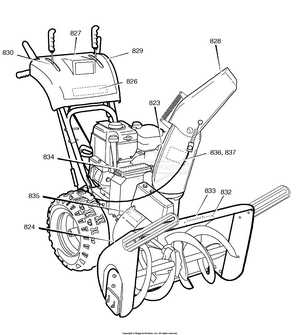

How to Read a Snow Blower Parts Diagram

Understanding technical drawings of machinery is essential for anyone looking to repair or maintain their equipment. These visual guides provide a clear representation of each component’s position and function, making it easier to identify issues and determine the correct solutions. Learning how to read such schematics can significantly improve the repair process, saving both time and effort.

Identifying Key Components

The first step in interpreting these illustrations is identifying the main components. Most diagrams will categorize parts into groups based on their function, such as power transmission, control mechanisms, and structural supports. By becoming familiar with the terminology and visual indicators used in these schematics, you can quickly locate the part you need to examine or replace.

Understanding Labels and Numbering

Each component in the diagram is usually accompanied by a label or number that corresponds to a list of part descriptions. These labels can help you cross-reference the diagram with actual parts catalogs or online resources, making it easier to find the exact item you need. Pay close attention to these identifiers to ensure you order the right parts for your repair or maintenance task.

Common Craftsman Snow Blower Repairs

Every machine that operates in demanding conditions is subject to wear and tear, especially after prolonged use. When issues arise, it’s important to know the common areas that often require attention. Regular maintenance and prompt repairs can extend the life of your equipment, ensuring it continues to perform effectively when needed most.

Engine and Power System Troubleshooting

One of the most common issues faced by users is a malfunctioning power system. This could be caused by faulty spark plugs, fuel line blockages, or improper fuel mixtures. Diagnosing and addressing these problems early on can prevent larger engine failures down the road. Regular checks of fuel systems and spark plugs will help avoid inconvenient breakdowns.

Drive and Chute Mechanism Repairs

The drive system and chute components are often subjected to intense stress during use. Over time, belts, cables, and gears may become worn or misaligned. Addressing these problems promptly by adjusting or replacing parts can improve both the machine’s performance and safety. Ensuring these elements are in good working condition is vital to maintaining efficiency during operations.