Properly maintaining your outdoor machinery requires a clear understanding of its internal components. When a breakdown occurs or a replacement is needed, knowing how each part functions can make the repair process more straightforward. Identifying the right pieces and their connections helps prevent costly mistakes and ensures efficient performance over time.

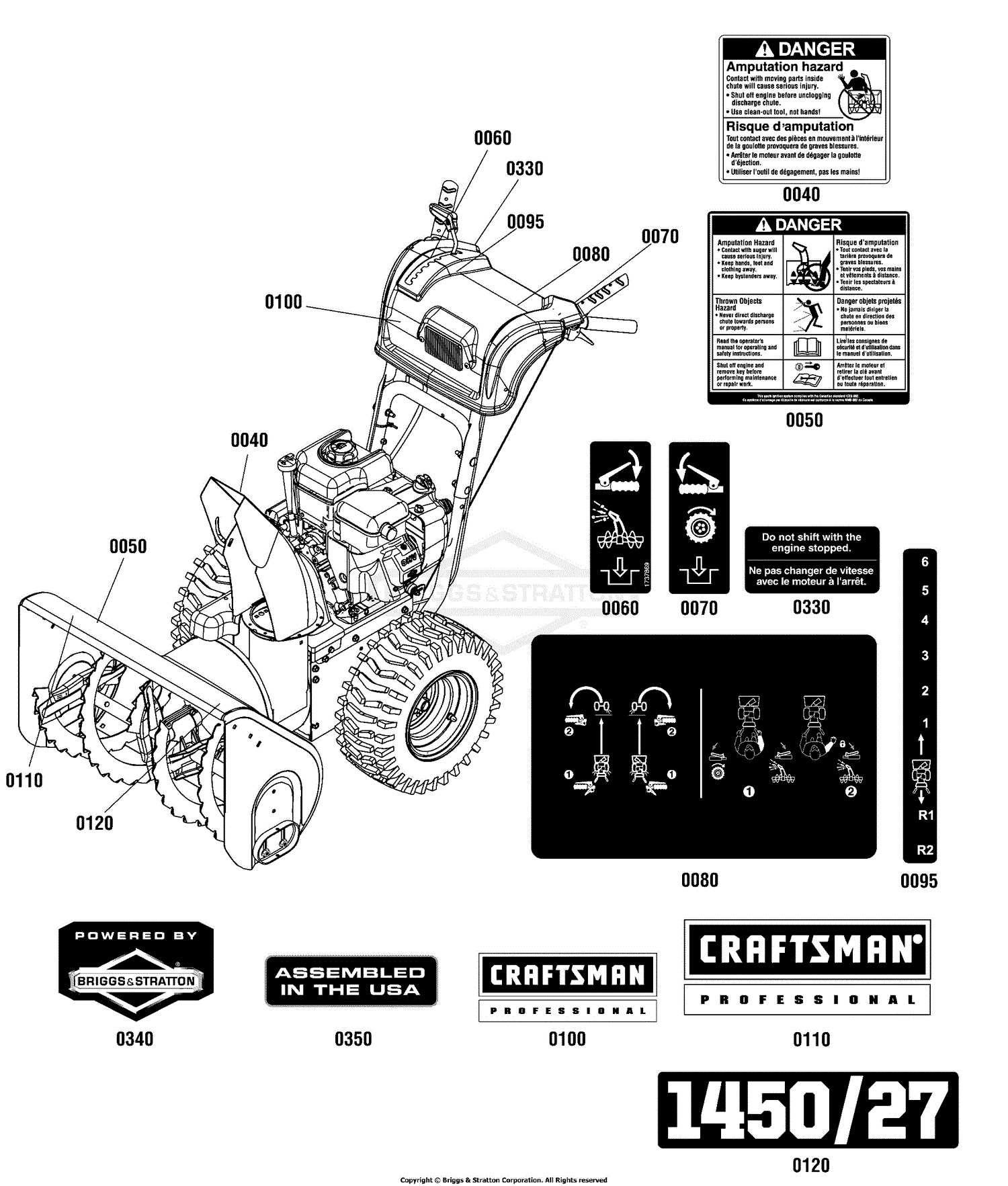

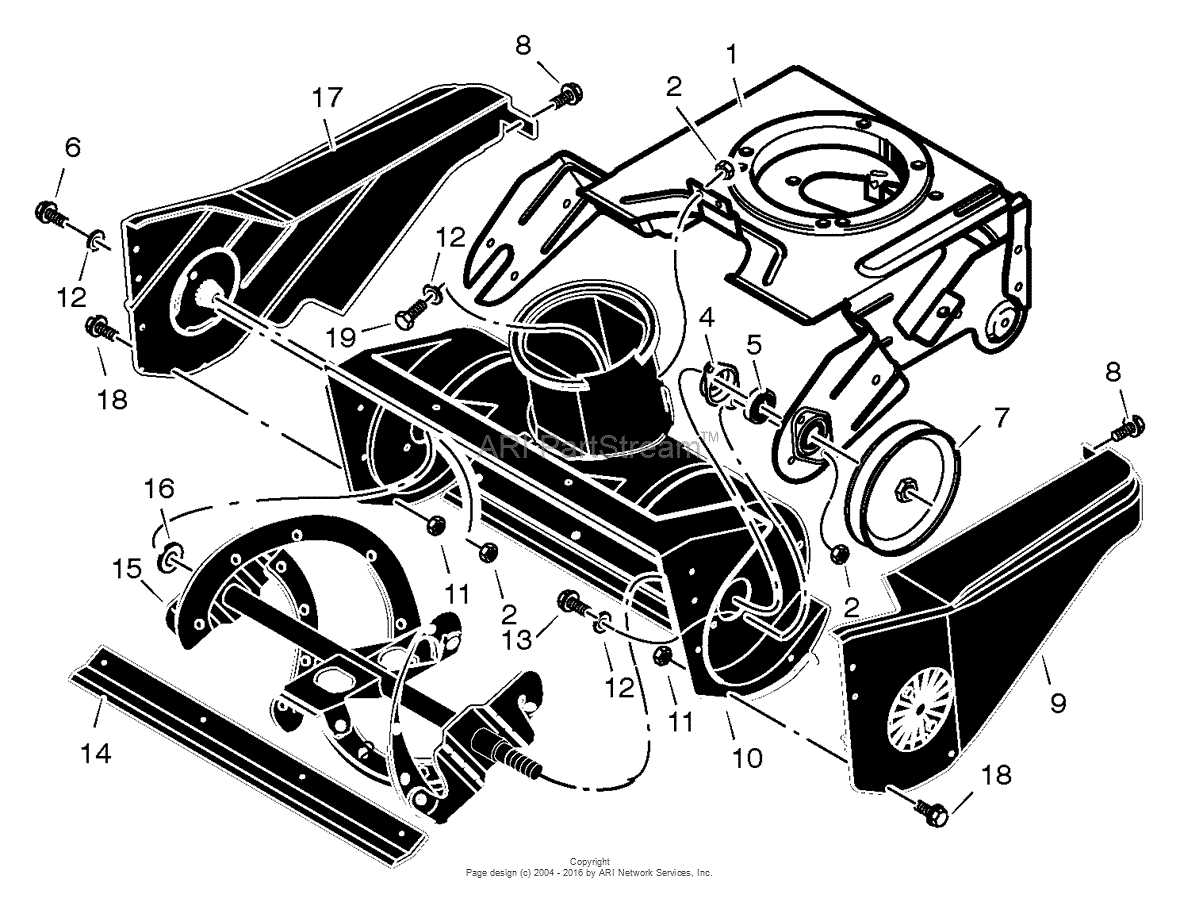

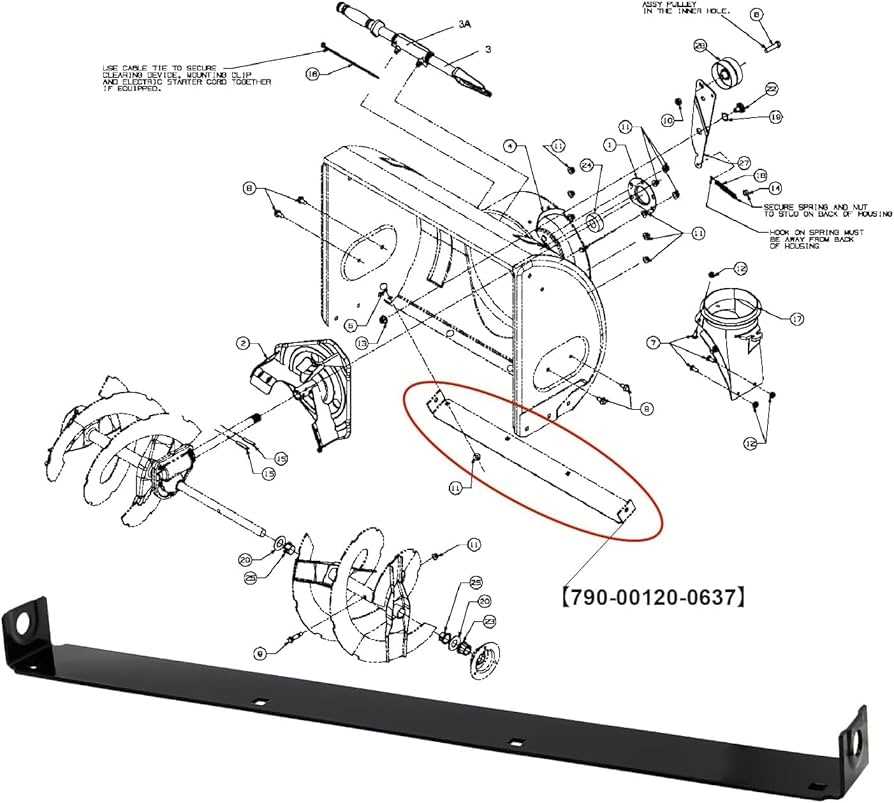

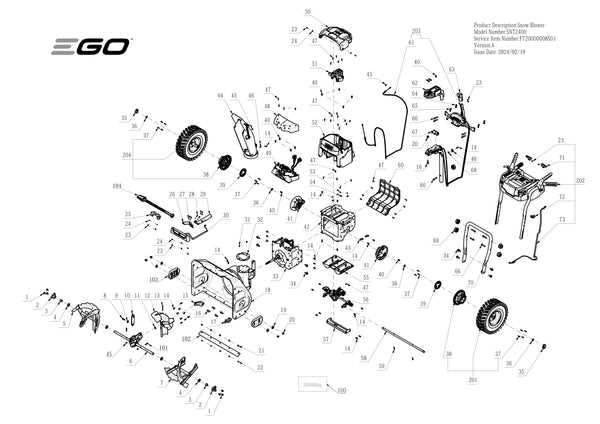

Detailed illustrations and guides are invaluable tools when navigating through the assembly and repair of your machine. These visual resources highlight key elements, providing insight into their locations and functions. With this knowledge, you can confidently troubleshoot issues and perform maintenance tasks on your equipment.

Whether you’re a beginner or a seasoned user, familiarizing yourself with the structure of your machinery can save time and improve overall efficiency. Understanding the components inside your equipment is essential for long-term upkeep and ensuring that it operates smoothly season after season.

Understanding the Components of Your Outdoor Equipment

Knowing the key elements of your outdoor machinery helps ensure smooth operation and effective troubleshooting. Each component plays a crucial role, whether it’s for movement, power, or control. Understanding how the parts fit together makes it easier to identify problems and perform necessary repairs.

Key Components and Their Functions

Each section of your equipment is designed to perform a specific function that contributes to its overall performance. The major groups can be broken down as follows:

- Engine and Power System – Responsible for generating the force required to operate the machine.

- Drive Mechanism – Transmits power from the engine to the moving parts, allowing your equipment to function as intended.

- Handling and Steering – Includes controls and mechanisms that allow for easy maneuvering and direction adjustments.

- Collection and Discharge System – Manages the intake, movement, and expulsion of debris or material.

Importance of Regular Inspection

Routine checks and familiarity with the setup of your machine can prevent wear and damage to individual components. It’s important to regularly inspect the following areas:

- Examine the engine for any signs of wear or malfunction.

- Check the drive components for alignment and any visible damage.

- Ensure the handling mechanisms are responsive and not obstructed.

- Inspect the discharge system for any blockages or breakdowns.

Regular maintenance ensures that each part remains in good working condition, allowing for efficient operation and reducing the need for costly repairs.

How to Read an Equipment Assembly Guide

Understanding visual guides for your equipment is essential for quick and accurate repairs. These illustrations provide a clear layout of the different components and how they are connected. Being able to read and interpret these guides properly helps in identifying the correct parts, their orientation, and the order in which they should be assembled or replaced.

Familiarizing Yourself with the Symbols

Many guides use specific symbols and notations to represent various parts. These markings are universally recognized and can indicate several things such as:

- Part Identification Numbers – Each component is assigned a unique number for easy reference.

- Arrows – Show the direction in which components should be placed or moved.

- Part Size and Specifications – Sometimes, measurements or size specifications are listed beside the symbols to aid in proper replacement.

- Connection Points – Indicate where parts must be joined together.

Step-by-Step Interpretation of the Guide

When interpreting the guide, it’s important to follow a step-by-step approach:

- Start by locating the part number or the area of concern in the illustration.

- Ensure the symbols match with the real-world components for better accuracy.

- Check the directional arrows or connection points to understand the proper alignment.

- Verify each piece’s size or specifications against the parts available for replacement.

By following these steps, you can avoid errors and perform effective repairs or replacements with confidence.

Common Issues and Component Identification

Knowing the most common issues that arise in your outdoor equipment helps in diagnosing problems quickly. Often, these issues can be traced back to a specific malfunctioning part or wear in the components. Properly identifying the problem areas is essential for effective repairs and maintenance.

Frequent Problems and Their Causes

Understanding the typical issues that occur with outdoor machinery can guide you to the correct solution. Some of the most frequent problems include:

- Engine Stalling – May be caused by a clogged fuel system or faulty spark plug.

- Loss of Power – Often results from a malfunction in the drive system or a worn-out belt.

- Unusual Noise – Can indicate a problem with the gearbox or bearings.

- Difficulty in Movement – Usually due to issues in the transmission or drive mechanism.

How to Identify Malfunctioning Components

To identify which part is causing the issue, it’s important to perform a systematic check:

- Listen carefully to unusual sounds and locate the source of the noise.

- Inspect the belts and drive components for any visible damage.

- Check for leaks or cracks in the fuel or exhaust systems.

- Ensure all connections are secure and free from obstruction.

By performing these checks, you can narrow down the possible malfunctioning parts and proceed with the necessary repairs or replacements.

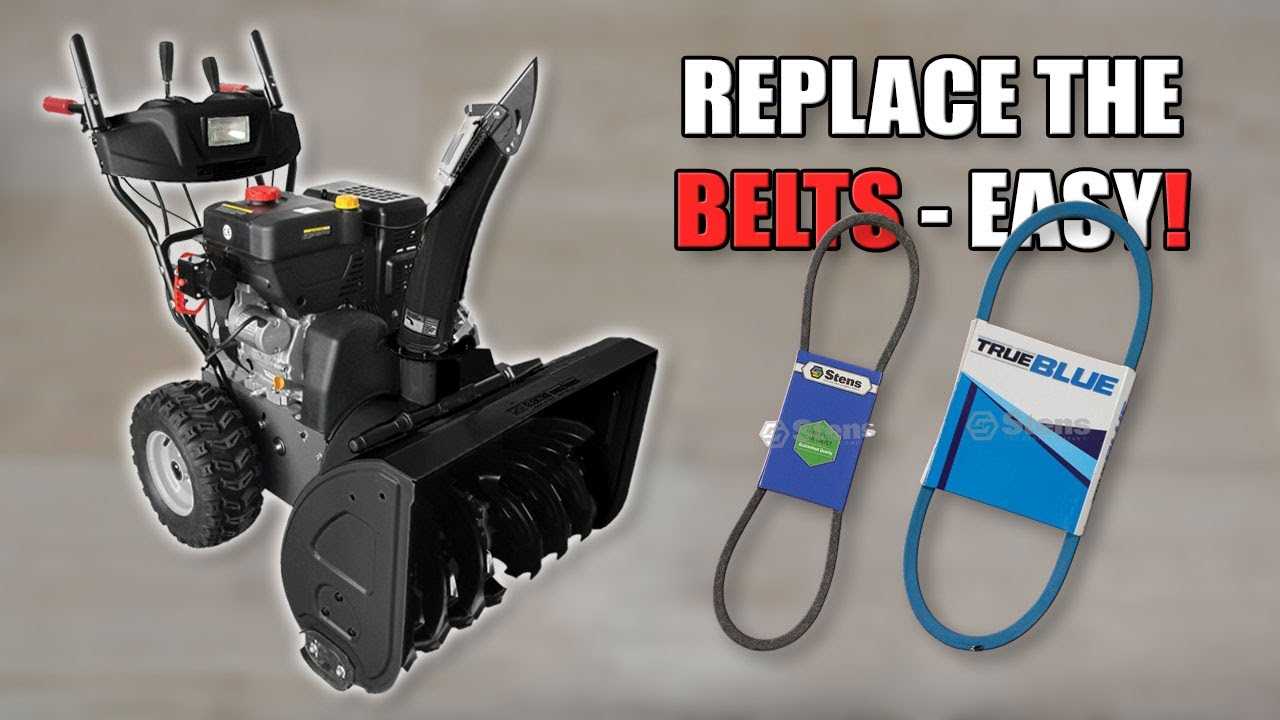

Replacing Faulty Components on Outdoor Equipment

When a component of your machinery malfunctions or wears out, replacing it promptly can prevent further damage and ensure optimal performance. Understanding how to properly remove and install new parts is crucial for maintaining efficiency. This section covers the general process of replacing malfunctioning components on various models, offering practical advice for effective repairs.

Before beginning, always ensure the equipment is turned off, and any residual power is disconnected. This is critical for safety when handling internal components.

Step-by-Step Guide for Replacing Faulty Components

Follow these basic steps when replacing faulty components:

- Identify the malfunctioning component through inspection or using a visual guide.

- Gather the necessary tools and replacement parts that match the specifications.

- Carefully remove the damaged component, taking note of its placement and connections.

- Install the new component, ensuring it is aligned and securely fastened.

- Test the equipment to verify that the replacement was successful and the issue is resolved.

Common Components and Replacement Process

Below is a table summarizing some common components that may need replacing and the general process involved:

| Component | Signs of Failure | Replacement Process |

|---|---|---|

| Drive Belt | Slipping, loss of movement | Remove the cover, detach old belt, install new belt, reassemble |

| Fuel Line | Leaks, poor fuel flow | Detach fuel lines, replace with new hoses, secure connections |

| Blade Assembly | Worn edges, inefficient cutting | Remove old blades, align and attach new blades, tighten fasteners |

Following these steps ensures the proper replacement of components, helping maintain the equipment’s longevity and performance. Always refer to the equipment’s manual or diagram to ensure compatibility with replacement parts.

Maintaining Your Outdoor Equipment for Longevity

Proper maintenance is key to extending the life of your outdoor machinery and ensuring it performs efficiently over time. Regular care helps prevent wear and tear, reduces the risk of major breakdowns, and allows you to address small issues before they become costly problems. Implementing a consistent maintenance routine is an investment in both time and money, as it can avoid unnecessary repairs and replacements.

Essential Maintenance Practices

To keep your equipment running smoothly, consider these basic maintenance steps:

- Clean after every use – Remove any debris or buildup that could affect performance.

- Lubricate moving parts – Keep gears, handles, and other components well-lubricated to reduce friction and prevent damage.

- Inspect fuel lines and filters – Regularly check for clogs or leaks in the fuel system, and replace filters as needed to maintain proper flow.

- Sharpen blades or augers – Keep cutting or moving components sharp to ensure efficient operation.

Seasonal Maintenance Checklist

In addition to regular upkeep, be sure to follow a seasonal maintenance routine to prepare your equipment for each use:

- Before winter, check the engine oil and change it if necessary.

- Inspect the fuel system for any leaks or damage, and refill with fresh fuel.

- At the end of the season, clean and store the equipment properly to prevent rust or degradation over time.

- Perform a full inspection before starting the next season to ensure all components are in working condition.

By committing to regular care and addressing minor issues promptly, you can ensure your machinery remains reliable and efficient for many seasons to come.