When maintaining or repairing machinery, knowing the layout of its components is crucial for efficient troubleshooting and replacement. A clear representation of each individual part allows users to easily identify what needs attention. Whether you’re a novice or an experienced technician, having an accurate map of the internal structure ensures the correct procedures are followed.

Effective repairs rely on recognizing the exact function and placement of each part. Without this understanding, it becomes challenging to perform tasks like replacing faulty elements or upgrading certain features. With the right visual guide, even the most intricate machine can be easily understood and serviced.

Replacing parts without proper knowledge can lead to costly mistakes and unnecessary downtime. Therefore, having access to reliable visual aids is an essential part of any repair process. This guide will provide a detailed overview of the necessary steps to identify, repair, and maintain your equipment with confidence.

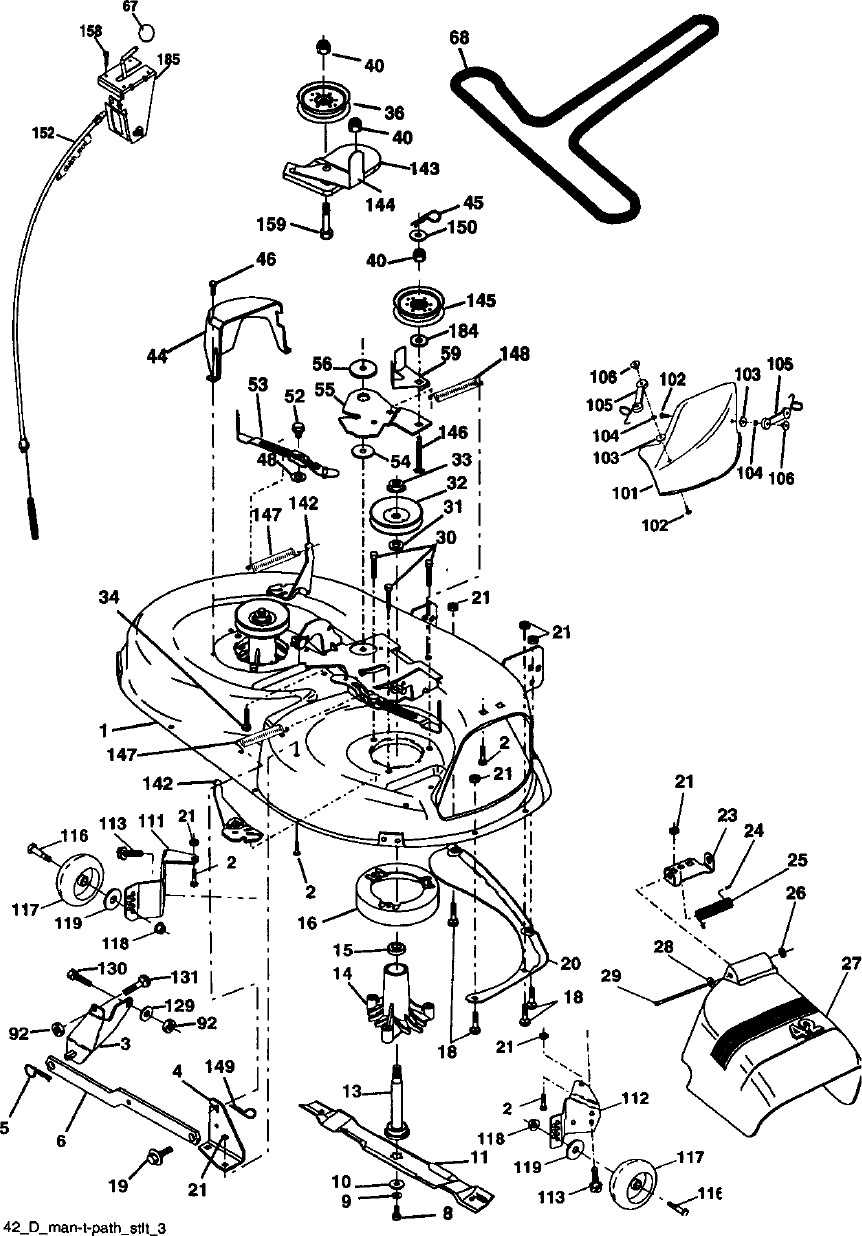

Understanding the Craftsman T3200 Parts Layout

To properly service a machine, it is essential to have a clear understanding of its internal components and how they interact. A well-organized layout can significantly ease the identification and troubleshooting of various elements. With a comprehensive visual representation, users can quickly pinpoint issues and determine what needs to be replaced or repaired.

Identifying Key Components

Each machine has a specific arrangement of parts that work together to ensure optimal performance. The ability to identify major components, such as the engine, transmission, and control system, is vital. A good layout allows you to understand how these parts are connected and helps in determining the most efficient repair process.

Efficient Repair and Maintenance

Once the key components are identified, maintenance becomes more manageable. With a clear understanding of the structure, replacing damaged or worn-out elements becomes a straightforward task. Additionally, this knowledge aids in performing preventive maintenance to avoid future issues, prolonging the machine’s life and ensuring smoother operation.

How to Identify Key Components in T3200

Recognizing essential elements of a machine is the first step in effective maintenance and repair. Understanding the role of each component and its location within the system allows users to easily assess the overall condition and determine the right approach for addressing any issues. With the proper knowledge, you can quickly identify what requires attention and prevent unnecessary repairs.

The most critical components to focus on include the engine, fuel system, transmission, and control systems. Each of these plays a vital role in the smooth operation of the equipment. By knowing where they are situated and how they function together, you can efficiently troubleshoot problems, whether it’s a performance issue or a mechanical failure.

Step-by-Step Guide for Parts Replacement

Replacing damaged or worn components requires a systematic approach to ensure proper installation and functionality. By following a structured guide, you can minimize the risk of errors and ensure that your equipment operates as expected. This process typically involves identifying the faulty element, obtaining the correct replacement, and carefully installing it according to the manufacturer’s specifications.

The first step is to power down and secure the machine to prevent any accidents during the repair. Next, carefully remove any parts obstructing access to the defective component. Once the faulty piece is located, ensure the new part matches the specifications and fits properly before securing it in place. Finally, test the system to ensure everything functions smoothly and that the repair is successful.