Understanding the layout of machinery components is essential for effective maintenance and repair. By familiarizing yourself with the arrangement of each part, you can troubleshoot issues with ease and ensure the equipment functions properly. A well-organized schematic or layout can provide clarity when working with complex systems.

Knowing how to read these configurations allows users to spot worn-out or damaged pieces early, which can save both time and money in the long run. The information provided can help owners make informed decisions when performing routine checks or replacing parts.

Whether you’re a seasoned technician or a DIY enthusiast, having a clear understanding of the mechanical setup is a valuable skill. This guide aims to simplify the process, providing you with the knowledge necessary to tackle repairs and maintenance effectively.

Understanding the Craftsman Tiller Parts Layout

Familiarizing yourself with the layout of machinery components is key to effective maintenance. When you have a clear understanding of how each element fits together, troubleshooting and repairs become much simpler. A comprehensive arrangement helps users identify which components require attention, ensuring that issues are addressed promptly.

Each section of the system serves a specific function, and recognizing these roles is essential when working with the equipment. This knowledge allows operators to assess the state of various elements and make informed decisions about necessary replacements or adjustments.

In this guide, we break down the layout into logical groups, providing a clear overview of key components and their interactions. Whether you are conducting routine maintenance or fixing specific issues, knowing the system’s structure will empower you to handle repairs more confidently and efficiently.

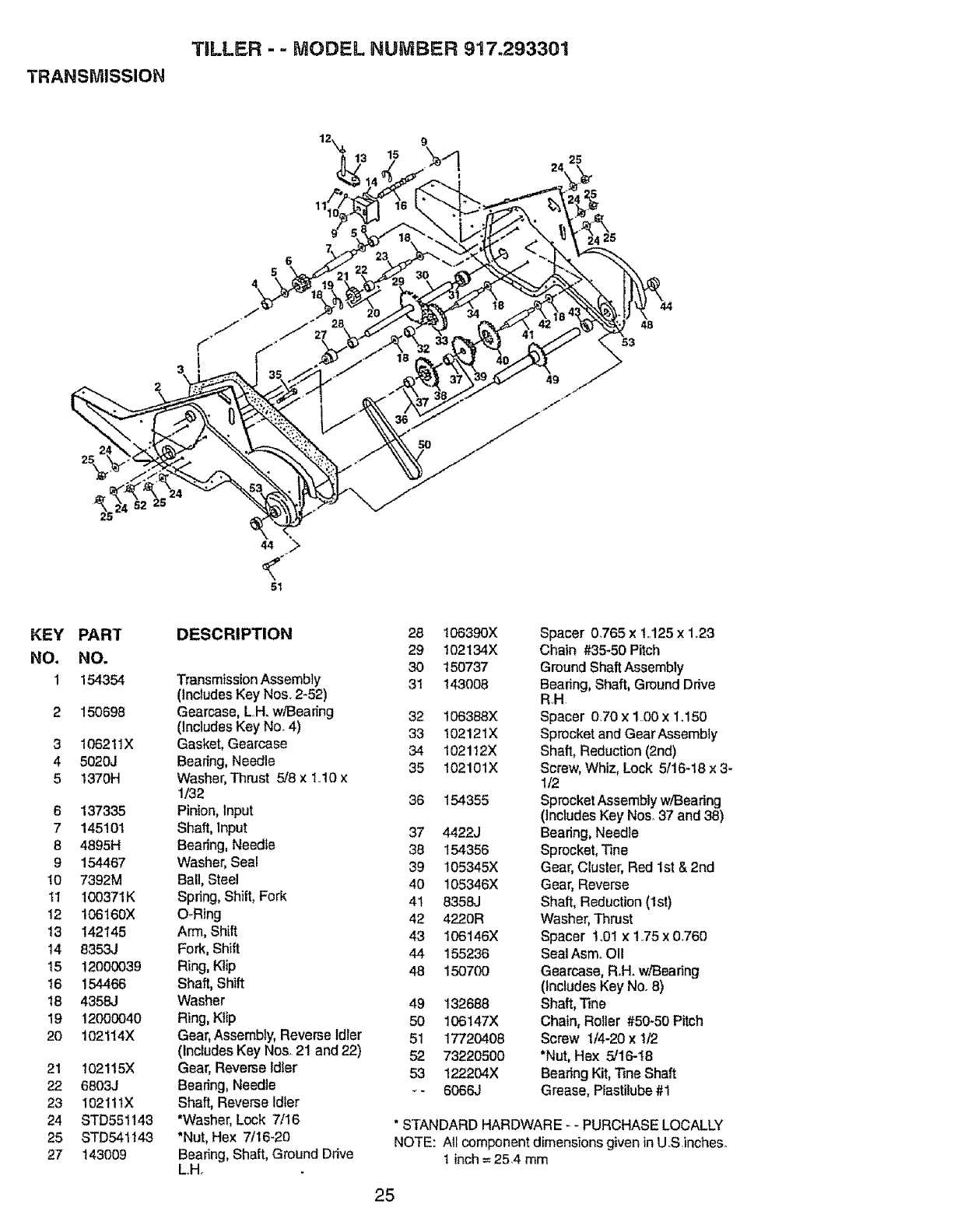

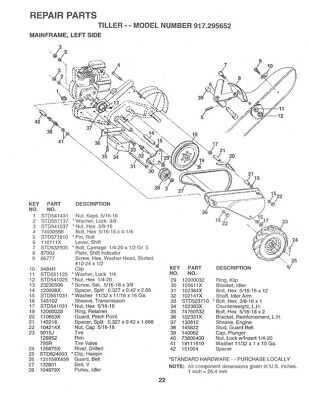

How to Identify Key Components in the Diagram

Understanding how to locate essential elements in a schematic is critical for efficient repairs and maintenance. Recognizing individual components and their specific roles in the system allows users to pinpoint issues quickly. A well-structured layout clearly marks each part, making it easier to identify what needs attention.

Focus on the larger sections first, as they typically house the most important elements. From there, narrow down to smaller components and connections that might be more intricate but equally vital. Being able to read the visual cues will help ensure that no part is overlooked during the diagnostic process.

Additionally, understanding common symbols and notations used in these layouts can significantly reduce the time spent on identifying the right parts. This knowledge enables a more streamlined troubleshooting process, ultimately leading to a faster and more accurate repair.

Maintenance Tips Using the 917 Parts Diagram

Proper upkeep of machinery requires regular inspection of key components to ensure everything is functioning optimally. With a clear understanding of the system’s layout, it’s easier to identify worn-out or malfunctioning parts before they cause major issues. This proactive approach can help prevent costly repairs and extend the lifespan of the equipment.

Start by checking high-wear areas, such as moving parts and connections that experience the most friction. These components often need more frequent attention to avoid breakdowns. Use the layout as a guide to systematically inspect each element, ensuring that nothing is missed.

Pay attention to any signs of corrosion or damage that could affect the system’s efficiency. For example, connections that show wear might require lubrication or tightening, while cracked parts should be replaced promptly. Regular checks, informed by the schematic, will help maintain smooth operation and prevent unexpected failures.