When maintaining and repairing outdoor machinery, it is essential to have a clear understanding of the internal structure and individual components. Proper knowledge helps ensure effective repairs and extends the life of the equipment. Whether you’re replacing worn-out pieces or performing routine upkeep, identifying the correct parts and their functions is crucial for smooth operation.

Familiarizing yourself with the different elements of your machine can save time and money. A detailed look at the various sections allows you to pinpoint the source of issues and make informed decisions about replacements. Clear visual aids and reference guides play a significant role in achieving this understanding.

Regular maintenance is key to ensuring that everything functions properly for years to come. Knowing what each component does and how it interacts with others will prevent costly repairs and improve overall efficiency. By following a structured approach, you can keep your equipment in top condition, ready for use whenever needed.

In order to properly maintain and repair equipment, it is important to understand the layout and structure of its essential elements. Every machine consists of multiple components that work together to ensure optimal performance. Recognizing how each part functions and interacts can significantly improve the maintenance process and avoid unnecessary downtime.

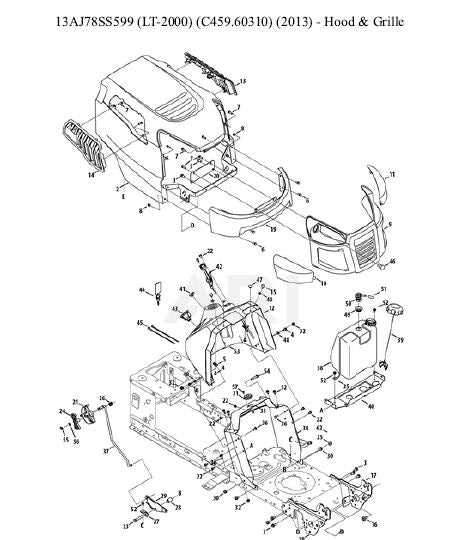

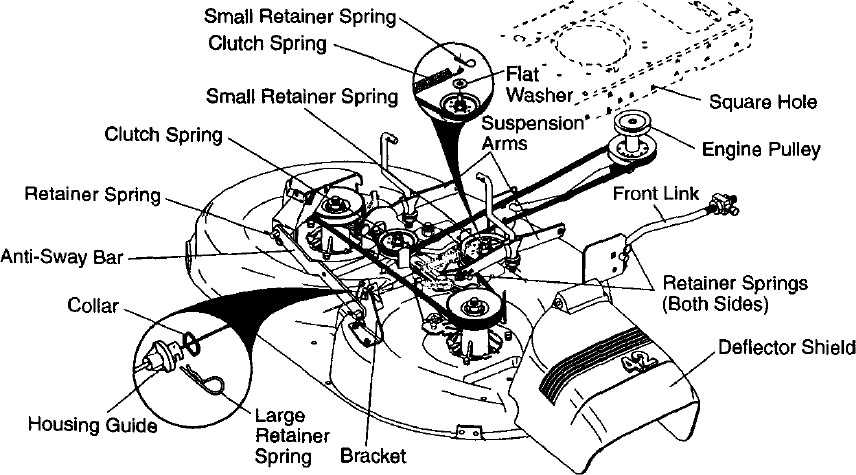

The breakdown of a machine is often illustrated through detailed reference materials that clearly depict the position and relationship between individual components. These visual aids serve as an essential tool for anyone seeking to troubleshoot, replace, or repair specific sections of the machinery.

| Component | Function | Location |

|---|---|---|

| Engine | Powers the system | Central area |

| Drive Belt | Transfers motion | Front section |

| Wheels | Provide movement | At the base |

| Battery | Stores power | Side compartment |

Understanding these components and their layout helps with effective troubleshooting and repairs. By referencing these guides, operators can easily find specific pieces, identify issues quickly, and perform necessary tasks with confidence. This knowledge is crucial for prolonging the life and reliability of any machine.

Identifying Key Parts of the Equipment

To maintain and troubleshoot machinery, it is essential to identify the key components that make up the system. Each piece plays a crucial role in ensuring the overall functionality of the equipment. Recognizing these elements allows you to pinpoint potential issues and perform repairs efficiently.

Among the most important components, you will find those responsible for generating power, providing mobility, and ensuring proper operation. Familiarity with their location and function will guide you in proper maintenance and replacement when necessary.

- Power Source: Typically located in the central area, this is where energy is generated to drive the machine’s functions.

- Motion Mechanism: This part transmits power to the wheels or other moving sections, enabling movement and operation.

- Control System: The interface that allows the operator to manage settings, speed, and other key functions of the equipment.

- Battery: Located in a compartment, it stores electrical energy that powers the system when needed.

- Transmission: Transforms the engine’s power into motion, transferring energy to the wheels or other mechanical parts.

By clearly understanding where these components are located and their function, operators can make informed decisions when performing maintenance tasks or identifying malfunctioning parts. A structured approach to component identification will reduce troubleshooting time and improve the longevity of the equipment.

When dealing with malfunctioning equipment, a structured approach to repairs is essential for efficiency and accuracy. Following a clear, organized method allows you to identify the problem, replace damaged components, and restore the machine to optimal functioning. This guide will walk you through the necessary steps to ensure that repairs are done correctly and safely.

Preparation for Repair

Before beginning any repair work, it is important to prepare both the equipment and your workspace. Ensure the machine is powered off and disconnected from any power source. Gather all the tools and replacement parts you may need, and clear the area of any obstructions to provide ample space to work.

Identifying and Replacing the Faulty Component

Once you’re ready to begin, identify the malfunctioning component using reference materials and visual guides. After locating the damaged part, carefully remove it by loosening any fasteners or screws that may be holding it in place. Once removed, install the new component, ensuring it is securely fitted and aligned correctly. Double-check the connections to ensure everything is in place before reassembling the equipment.

By following this method, you can tackle repairs with confidence, knowing that you have a systematic plan in place to restore functionality to your machinery.

How to Replace Key Elements

Replacing malfunctioning components is an essential skill for keeping equipment in good working order. By carefully following a set of instructions, you can efficiently remove the damaged part and install a new one, restoring full functionality to the machine. Understanding the process ensures that replacements are done safely and correctly, minimizing the risk of further damage.

Start by ensuring the equipment is completely powered off and disconnected from any energy sources. This step is critical for your safety. Next, locate the faulty part using the machine’s manual or a detailed guide, and assess how it is secured within the system.

Once you have identified the element that needs replacement, use the appropriate tools to carefully remove it. This may involve loosening screws, bolts, or other fasteners that are holding the part in place. After the defective component is removed, install the new one in the reverse order, ensuring all connections are secure and that everything is aligned properly.

Double-check your work before reassembling the machine to make sure the new part is fully functional and the equipment is safe to operate. Regularly inspecting and replacing damaged components will help extend the life of your machinery.

Proper maintenance is key to extending the lifespan and ensuring the reliability of any machine. Regular care and attention to detail can prevent wear and tear, reduce the likelihood of breakdowns, and keep the system running efficiently. By following a consistent maintenance routine, operators can maximize performance and avoid costly repairs in the future.

Start by regularly inspecting the machine for any signs of damage or wear. Check key components such as the power source, moving parts, and structural elements for cracks, rust, or loose connections. Cleaning these parts is equally important, as dirt and debris can cause friction and accelerate deterioration over time.

Another essential part of upkeep is lubricating moving parts to reduce friction and prevent unnecessary wear. Keep all mechanical elements well-lubricated to maintain smooth operation and avoid overheating. Additionally, ensure that any electrical systems are regularly checked and serviced to keep them functioning properly.

By staying on top of routine tasks, you can ensure the equipment remains in excellent condition, ready to perform reliably for years to come.