Maintaining complex garden machinery requires a clear understanding of its internal structure and key components. By familiarizing yourself with how each part functions, you can ensure smooth operation and prevent unnecessary breakdowns. This guide aims to provide an in-depth look at the essential elements that make up a high-performance gardening tool.

Effective maintenance relies on knowing how the various pieces fit together. Whether you are performing a repair or simply conducting regular checks, understanding the connections between each mechanism will improve your ability to troubleshoot and extend the life of your equipment.

Exploring the inner workings of a machine not only simplifies the maintenance process but also enhances overall efficiency, ensuring that your tool works optimally throughout the season. Knowing where to focus attention and which components need regular care can save both time and money in the long run.

Understanding the Craftsman Tiller Transmission

At the heart of any powerful gardening tool lies a complex system that enables effective soil cultivation. This mechanism plays a vital role in transferring energy from the engine to the working components, allowing the equipment to function smoothly and efficiently. Gaining insight into how this system works helps ensure longevity and reduces the likelihood of mechanical issues.

Key Functions and Role

The core function of this system is to manage the distribution of power, directing it to various sections of the machine that perform the actual digging, cutting, or turning. Without this crucial system, the engine’s power would be ineffective, leading to poor performance or even failure to function. Understanding how this energy is transferred ensures that each part is functioning as intended and provides a foundation for troubleshooting.

Common Issues and Solutions

Like any mechanical system, this setup can face issues over time, especially with heavy use. Problems such as worn-out components or misalignments can reduce efficiency or lead to operational failures. Regular checks and proper maintenance can help identify potential issues early, allowing you to address them before they become major problems. Knowing what to look for, from loose connections to damaged elements, makes it easier to keep your equipment in peak condition.

Key Components of the Rear Tine Mechanism

Understanding the individual components of any complex garden tool is essential for both efficient operation and proper maintenance. Each part within the system works together to facilitate smooth functioning, ensuring the equipment performs at its best. In this section, we will explore the primary elements that contribute to the system’s overall efficiency.

Essential Mechanical Elements

The key components of this system are designed to interact seamlessly with one another, providing stability and power distribution. These elements include drive gears, belts, and rotational mechanisms, which work in unison to ensure that energy is transferred correctly. Each part is integral to the overall operation, with even the smallest malfunction potentially leading to significant performance issues. Recognizing how these components interact helps in diagnosing any faults and performing effective repairs.

Maintenance and Troubleshooting

Regular inspection of these components is critical for avoiding wear and tear that can disrupt functionality. Issues such as misalignment, rust, or damage to moving parts can impact the effectiveness of the entire system. Timely lubrication and careful alignment of these elements can help maintain optimal performance, while early identification of potential problems prevents costly repairs. Understanding the role of each component is key to troubleshooting and ensuring that your equipment remains in top condition.

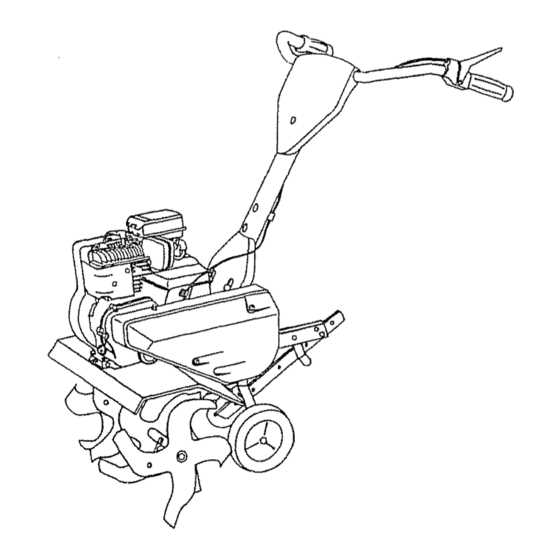

How to Read the Tiller Parts Diagram

To effectively maintain and repair your garden equipment, understanding the layout of its components is essential. A well-constructed visual representation of the system shows how different elements fit together and interact. Knowing how to interpret this visual guide helps you identify parts, their functions, and the steps needed for repair or replacement.

Interpreting Labels and Symbols

The first step in understanding any guide is recognizing the labels and symbols used to represent each component. Each item is typically marked with a unique reference number or letter, which corresponds to a list that provides additional details. These references allow you to quickly locate specific elements and understand their role in the overall system. Proper identification of these markers is crucial to avoid confusion during repairs or assembly.

Identifying the Relationship Between Components

Once you’ve identified the individual components, the next step is understanding how they work together. The arrangement on the visual guide usually shows the flow of energy or motion between parts, helping you grasp how the system functions as a whole. Pay attention to the connections between components and how they are linked by gears, belts, or shafts. By recognizing these connections, you can better diagnose issues and understand how each part contributes to the machine’s performance.