Understanding the internal structure of household machines is essential for effective maintenance and repair. Every device is made up of different elements, each with a specific function to ensure proper operation. Knowing these components allows for quicker diagnostics when issues arise, saving time and effort.

By examining the visual layout of these elements, users can easily pinpoint where problems might occur and how to address them. This knowledge not only simplifies the troubleshooting process but also empowers individuals to handle minor repairs themselves.

Maintenance is key to prolonging the lifespan of any device, and having a solid grasp of its construction plays a significant role. A well-maintained machine functions more efficiently, reducing the need for costly repairs and enhancing overall performance.

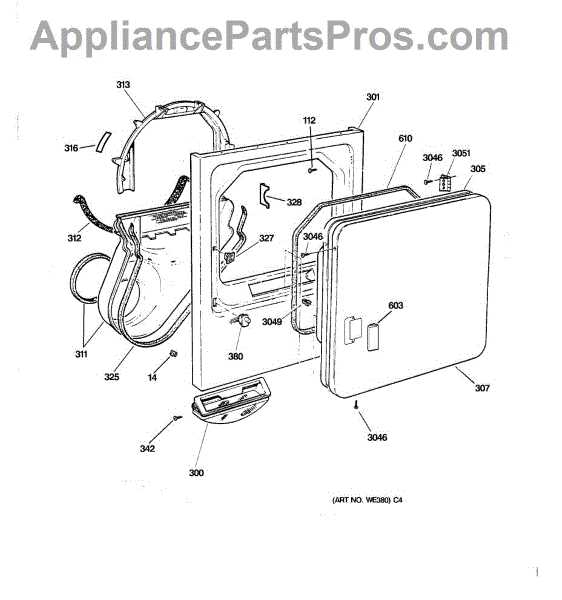

Understanding GE Electric Dryer Components

When it comes to household appliances, recognizing the different elements that work together to make a machine function is crucial. Each part serves a unique role, ensuring smooth operation and effective performance. Familiarizing yourself with these components helps in troubleshooting, maintenance, and extending the life of your appliance.

Here are some key parts commonly found in these machines:

- Heating Element: Responsible for generating the necessary heat for drying clothes.

- Drum: The rotating cylinder where clothes are placed for drying.

- Motor: Powers the drum and other moving components of the machine.

- Thermostat: Monitors the temperature inside the appliance to prevent overheating.

- Ventilation System: Ensures hot air is expelled from the unit safely and efficiently.

Each of these components plays a critical role in ensuring your appliance works as expected. Understanding how they interact allows for better decision-making when it comes to repairs or replacements.

Identifying Key Parts in the Diagram

When examining the layout of a machine, it’s important to recognize the various components and understand their specific functions. A clear understanding of each element allows for quicker troubleshooting and easier repairs. This knowledge is especially valuable when diagnosing issues or replacing faulty components.

Key elements in the internal structure often include:

- Heating Unit: The mechanism that generates the heat required for drying items.

- Rotating Drum: This is where the items are placed and spun to dry them effectively.

- Drive Motor: Responsible for powering the movement of the drum and other related functions.

- Thermal Sensor: Monitors and regulates the internal temperature to prevent overheating.

- Exhaust System: Directs hot air outside to ensure the appliance operates efficiently.

Identifying these key components within the structure helps users understand how the machine operates and can pinpoint specific areas that may need attention when performance issues arise.

How to Troubleshoot GE Dryer Issues

When an appliance stops working as expected, troubleshooting becomes essential to identify the source of the problem. A methodical approach helps to pinpoint the issue quickly, reducing downtime and avoiding unnecessary repairs. By understanding the functions of key components, users can assess potential malfunctions and take corrective actions.

Here are some common troubleshooting steps to follow:

- Check the power supply: Ensure that the appliance is properly connected and receiving power.

- Examine the heating mechanism: If items aren’t drying effectively, it could be due to a faulty heating unit.

- Inspect the drum: If the drum isn’t turning, the drive motor or belt may need attention.

- Test the temperature control: A malfunctioning thermostat can prevent the machine from reaching the desired temperature.

- Clear the venting system: Blockages in the ventilation can reduce efficiency and cause overheating.

By following these steps, you can often identify the root cause of the issue and determine whether a simple fix or a more detailed repair is necessary.