When working with machinery, it’s essential to have a clear understanding of its internal mechanisms. Knowing how the various components interact with each other ensures that the system functions smoothly and efficiently. By familiarizing yourself with the different parts, you can troubleshoot issues, perform necessary repairs, and maintain the overall health of the equipment.

Proper maintenance involves recognizing each element’s role and how they contribute to the machine’s overall performance. With the right knowledge, you can handle simple adjustments or more complex fixes without the need for professional assistance. This article will guide you through the process of identifying the crucial components and understanding their functions.

Whether you are an enthusiast or a professional, having a visual reference of the parts can significantly enhance your ability to work with and maintain machinery. With this information, you will be well-prepared to tackle maintenance tasks confidently and effectively.

Understanding the 25 HP Kohler Engine Parts

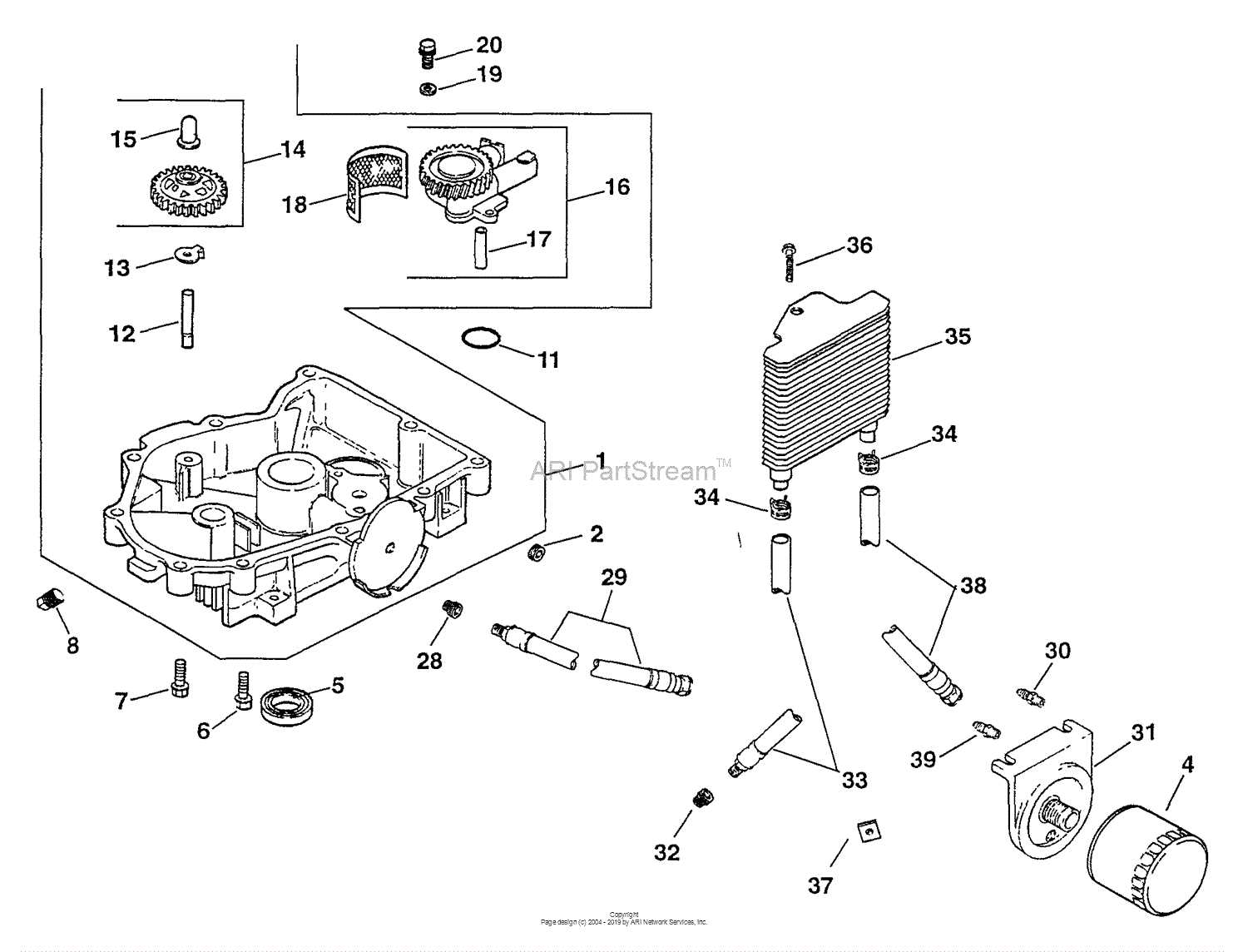

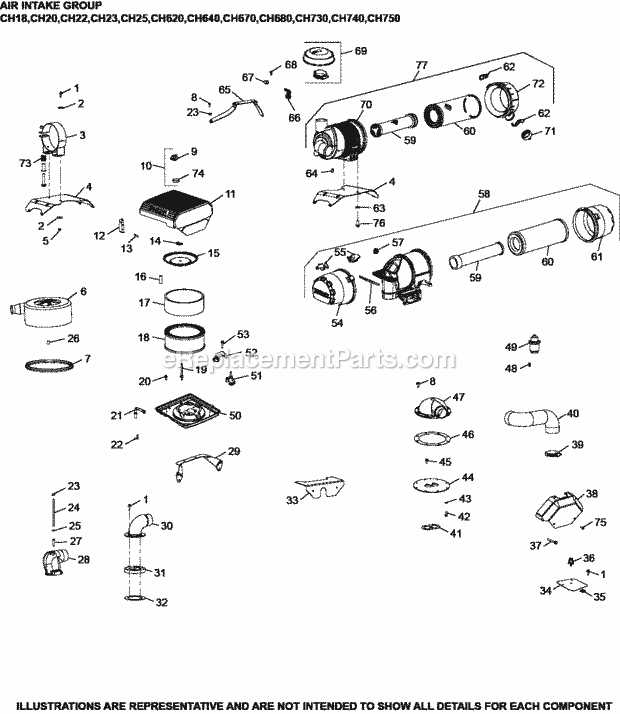

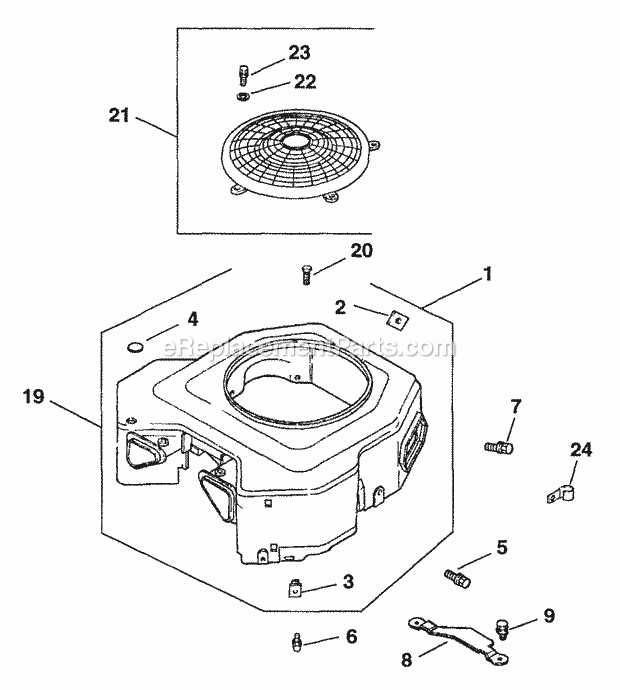

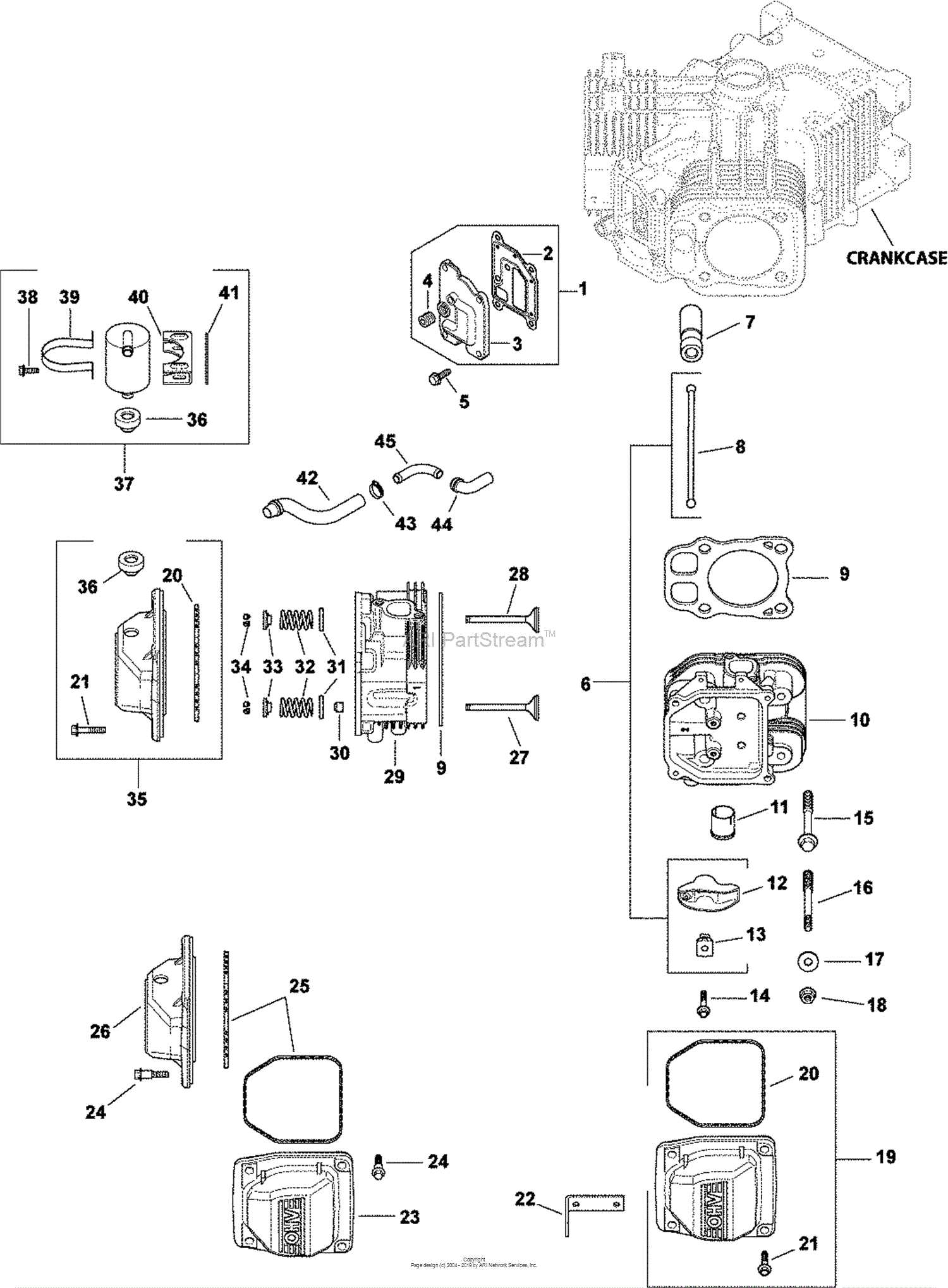

Each machine is built with a variety of key elements that work together to ensure smooth operation. Recognizing the function of each component allows for better understanding and effective maintenance. In this section, we will explore the main components that make up a 25 HP unit, focusing on their roles and how they interact within the system.

The primary elements include the power delivery system, which ensures that energy is efficiently transferred from the source to the working mechanisms. Additionally, critical systems such as the fuel and exhaust mechanisms play an essential role in optimizing performance. Understanding these basic structures is vital for troubleshooting and maintaining the unit’s long-term health.

Proper care for each component involves not just regular inspection but also knowing how to detect potential issues early. By becoming familiar with the components’ layout and functions, you’ll be better equipped to handle repairs and adjustments, ultimately prolonging the life of the equipment.

How to Identify Key Engine Components

Recognizing the essential components of any mechanical system is crucial for effective troubleshooting and maintenance. Each part plays a specific role, and understanding their layout and function can help in identifying issues before they become major problems. This section will guide you through the process of spotting the most important parts of the system.

Start by focusing on the power transmission unit, which directs energy from the source to the operational elements. Next, pay attention to the fuel system, which ensures that the unit receives the right amount of fuel for efficient operation. The cooling and exhaust components are equally important for maintaining optimal temperatures and ensuring smooth functioning.

Familiarizing yourself with these critical components not only helps in routine inspections but also prepares you to act quickly when a problem arises. With practice, identifying each part and understanding its purpose becomes easier, leading to more effective maintenance and longer-lasting equipment.

Common Maintenance Tips for Kohler Engines

Proper care and upkeep are essential for ensuring the long-term functionality of any machinery. Regular maintenance prevents major issues and helps keep systems running smoothly. In this section, we’ll cover some practical tips that will help extend the life of your equipment and improve its performance.

- Regular Oil Changes: Change the lubricant at recommended intervals to keep internal components well-lubricated and reduce wear and tear.

- Clean or Replace Air Filters: Air filters ensure clean airflow, which is crucial for efficient combustion. Clean or replace them regularly to prevent dirt buildup.

- Check Spark Plugs: Inspect the spark plugs for wear and replace them when necessary. Faulty spark plugs can lead to poor performance.

- Inspect Fuel Lines: Over time, fuel lines can crack or become clogged. Inspect them regularly and replace any damaged sections to avoid fuel delivery issues.

- Monitor Cooling System: Ensure that the cooling system is functioning properly to avoid overheating. Regularly clean cooling fins and check for blockages.

By following these simple yet effective maintenance steps, you can significantly reduce the risk of unexpected breakdowns and ensure the optimal performance of your machine. Regular checks and early intervention will help you avoid costly repairs in the future.