When dealing with powerful outdoor machinery, understanding the internal structure is crucial for proper maintenance and repairs. This guide will provide an insightful overview of the essential components that make up a 26 horsepower machine, focusing on how they work together to ensure smooth operation.

Proper knowledge of these key components allows users to troubleshoot, replace worn-out parts, and optimize performance. Whether you’re a mechanic or a hobbyist, having a clear visual representation and understanding of the core elements can make all the difference in achieving reliable functionality.

With this information, you can confidently approach any task, knowing exactly where to focus your attention and how to handle the machinery efficiently.

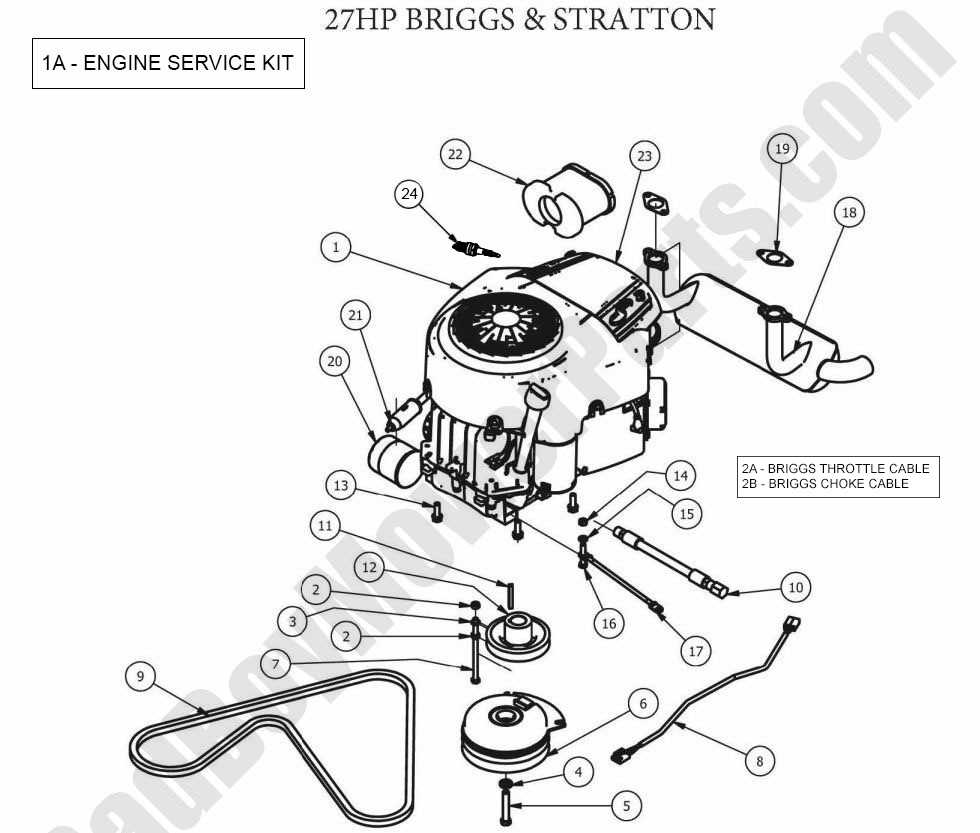

Overview of 26 HP Engine Components

Understanding the fundamental elements that drive a 26 horsepower outdoor machine is essential for effective maintenance and performance. Each component plays a vital role in the overall function, contributing to the power output and efficiency of the system. By identifying these key parts, users can ensure smoother operation and pinpoint issues quickly when troubleshooting.

The main components consist of critical systems such as the fuel delivery mechanism, ignition system, cooling structures, and mechanical linkages that connect them all. These systems are designed to work in harmony, facilitating reliable power generation and distribution for various tasks, from lawn care to more demanding outdoor projects.

Recognizing how these pieces fit together can significantly enhance your ability to diagnose problems, replace damaged items, and extend the lifespan of the machinery.

Detailed Breakdown of Engine Parts

Breaking down the core components of a 26 horsepower machine helps to understand how each function contributes to its performance. Every element, from the fuel system to the cooling system, works together to provide optimal power output. By analyzing each piece individually, users can better appreciate the complexity behind this powerful tool and how it operates efficiently.

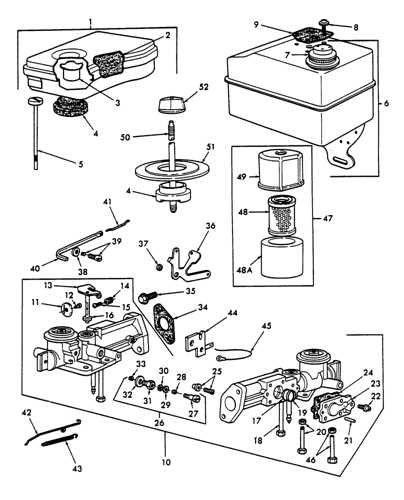

Fuel and Air Delivery Systems

The fuel system is responsible for ensuring a steady supply of fuel to the internal combustion area. It includes the fuel tank, pump, carburetor, and filters, all designed to deliver the right mixture of air and fuel to power the machinery. Any issue within this system, such as a clogged filter or malfunctioning carburetor, can impact the engine’s performance.

Ignition and Mechanical Systems

Another essential section involves the ignition and mechanical systems. The ignition system initiates the combustion process, utilizing spark plugs, coils, and flywheels. Meanwhile, mechanical systems such as pistons, crankshafts, and camshafts work to convert the energy created from combustion into motion, enabling the machine to perform various tasks effectively.

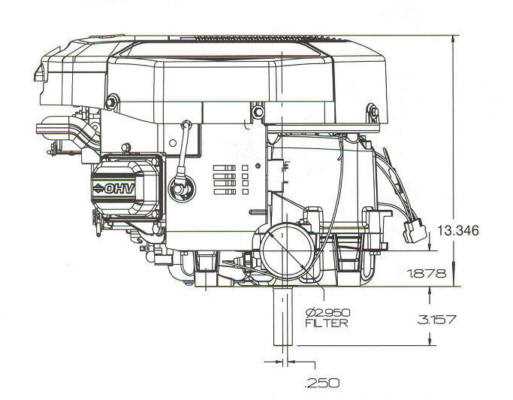

Understanding the Diagram for Maintenance

A clear visual representation of the internal components is an invaluable tool when it comes to maintaining powerful outdoor machinery. This schematic serves as a guide, offering detailed insights into how each component is interconnected, which helps in identifying potential problems and performing accurate repairs. Knowing how to interpret these visuals is crucial for effective troubleshooting and ensuring the longevity of the equipment.

With the diagram, users can easily locate specific areas that need attention, whether it’s for cleaning, lubrication, or replacement. By understanding the layout, maintenance tasks become more manageable, allowing individuals to take proper care of their machinery and keep it running smoothly over time.