When it comes to keeping machinery running smoothly, having a clear understanding of its individual components is essential. Each part plays a specific role, and recognizing how they fit together ensures better performance and longevity. This knowledge is especially valuable when it comes to repair or routine servicing tasks.

Identifying and diagnosing issues becomes much easier when you are familiar with the structure of the system. Whether you’re troubleshooting or performing maintenance, knowing what each element looks like and how it functions can save time and effort. Regular inspection of these elements is critical for optimal functionality.

Maintenance and care are at the core of extending the life of any mechanical system. By following proper procedures and using the correct tools, you can keep your equipment operating at peak efficiency. Understanding the layout and function of each component allows for quicker fixes and fewer costly repairs.

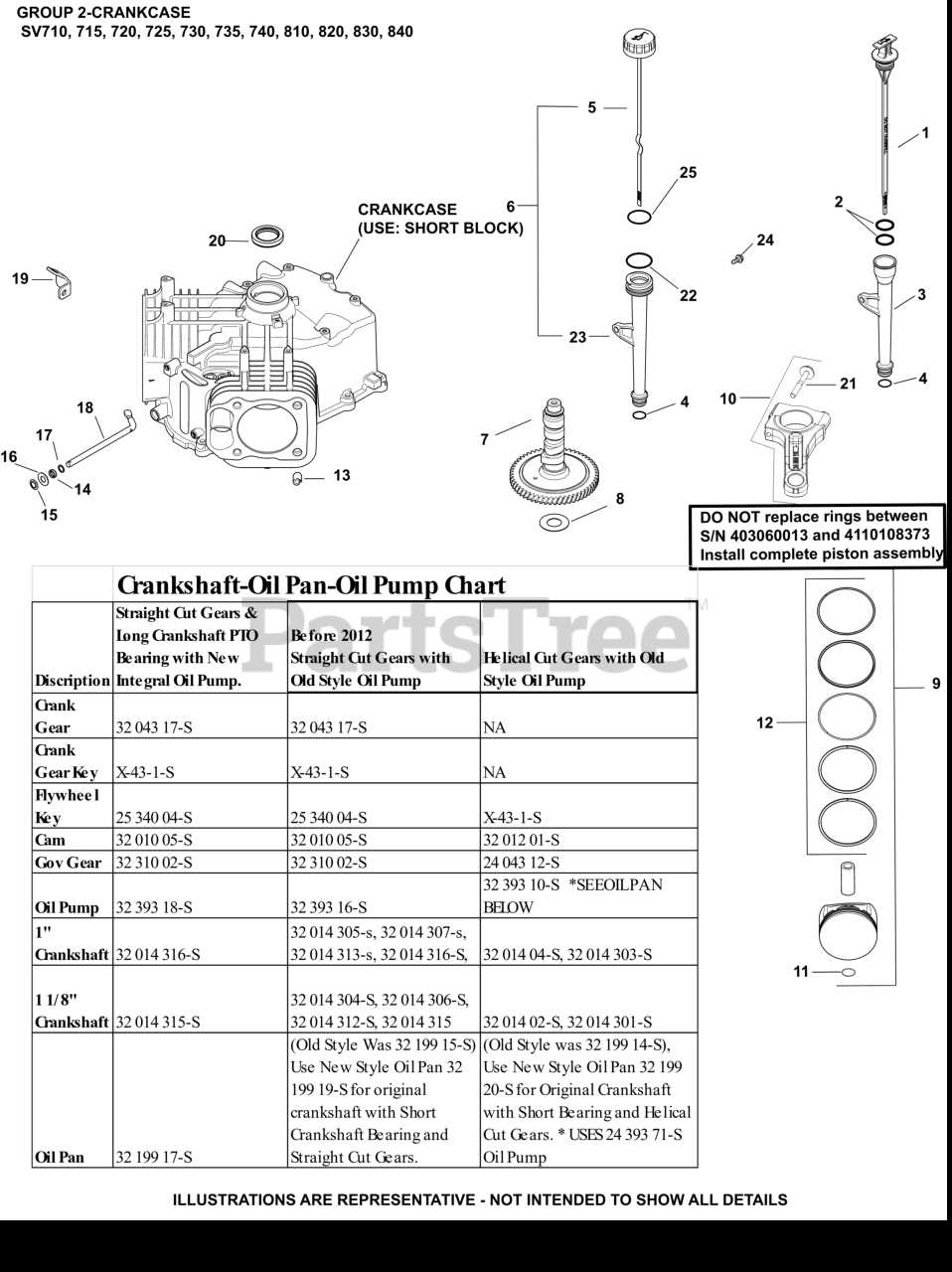

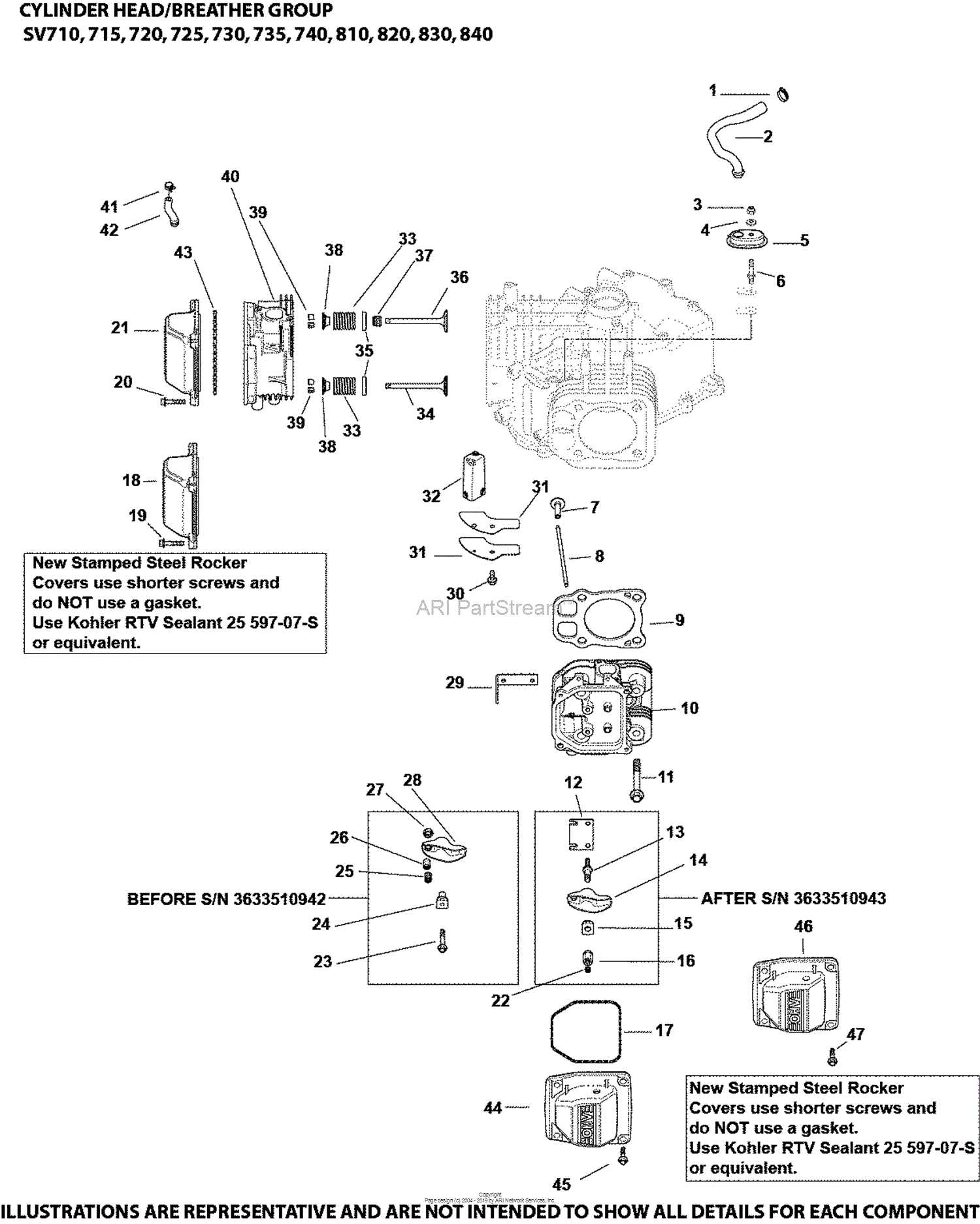

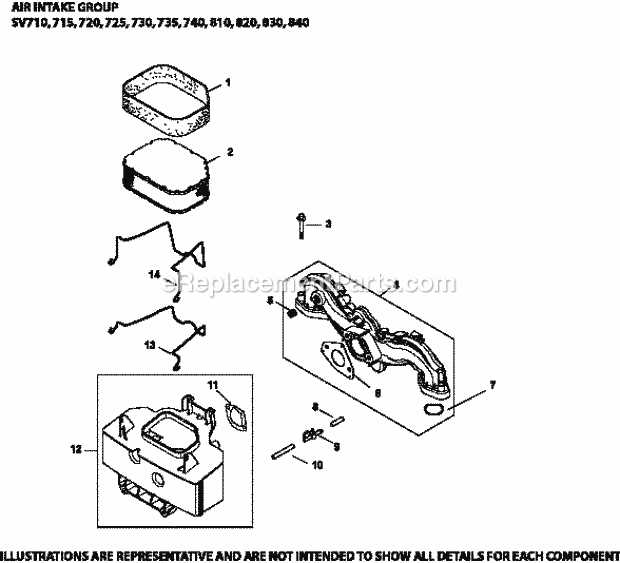

Understanding 26 HP Kohler Engine Components

The heart of any machinery lies in its individual elements, each serving a specific function to keep everything running efficiently. From the fuel system to the exhaust, each component plays a crucial role in ensuring proper operation. Having a thorough understanding of these pieces is vital when it comes to troubleshooting and regular upkeep.

Key Elements and Their Roles

In a system of this size and complexity, the major components work together seamlessly to deliver power and performance. The combustion system, for instance, ignites the fuel to create energy, while the lubrication system ensures that moving parts operate smoothly without friction. Other key pieces such as the air filtration system and cooling components prevent damage by regulating air intake and temperature.

Importance of Regular Inspection

Routine checks of the system’s components are essential to detect early signs of wear and prevent costly repairs. By staying informed about the functions of each element, you can easily identify areas that may need attention. Regular cleaning, oil changes, and part replacements help extend the longevity of the entire system.

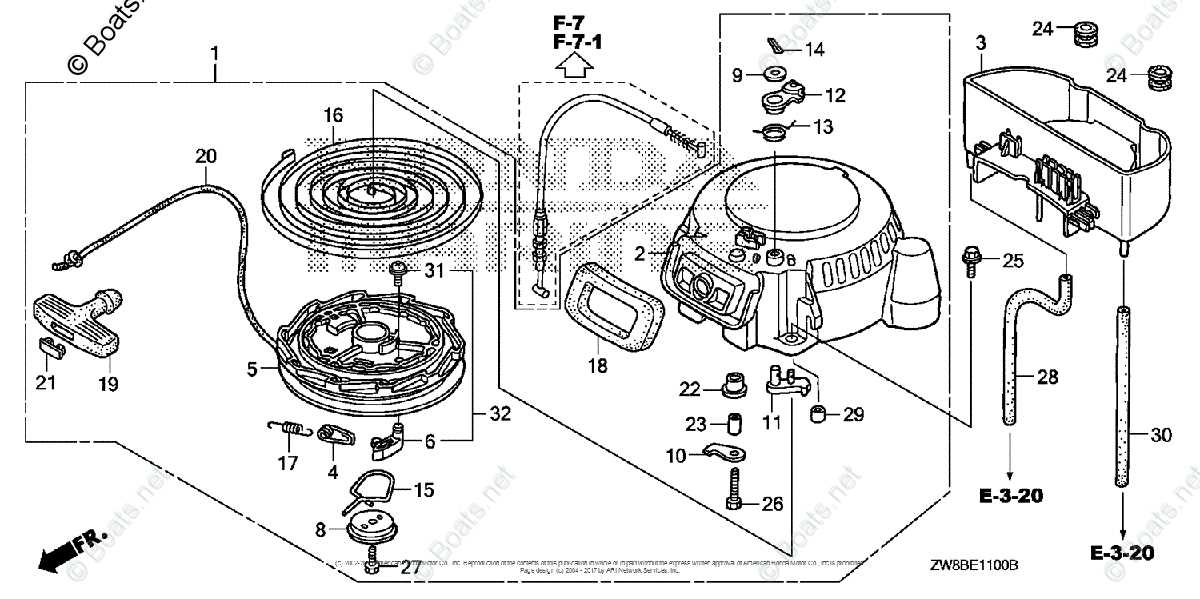

How to Identify Kohler Engine Parts

Recognizing the various elements of a complex mechanical system is crucial for proper maintenance and troubleshooting. Each component has a unique appearance and function that allows it to perform its specific task efficiently. Knowing how to identify these individual parts helps in diagnosing issues and performing repairs accurately.

One of the most important steps in identification is understanding the general layout and structure of the system. Whether you’re dealing with the fuel delivery, ignition, or cooling mechanisms, each section has distinguishing features. Taking note of these features, such as the shape and placement of specific components, will aid in recognizing their function within the larger system.

Labeling and organizing components during disassembly can also prevent confusion. When replacing or repairing any part, always refer to the system’s manuals or a comprehensive reference guide. This ensures that you’re working with the correct component and helps streamline maintenance procedures.

Maintenance Tips for 26 HP Kohler Engine

Proper upkeep is essential for maximizing the longevity and efficiency of any mechanical system. Regular maintenance not only helps avoid unexpected breakdowns but also ensures smooth operation. By staying proactive with routine checks and service tasks, you can avoid costly repairs and keep everything running at peak performance.

Oil changes are one of the most important tasks to perform regularly. Fresh oil ensures that all moving components remain lubricated, reducing friction and wear. Always use the recommended oil type and change it according to the manufacturer’s guidelines for optimal performance.

Another critical area to monitor is the air filtration system. Clean air filters help prevent debris from entering the system, which can cause blockages or damage. Replacing or cleaning the filters regularly is key to maintaining good airflow and efficient combustion.

Coolant levels should also be checked frequently. Keeping the cooling system topped up prevents overheating and maintains safe operating temperatures. Pay attention to any leaks or signs of coolant degradation and address them immediately.

Lastly, inspect the spark plug and fuel system regularly. Over time, spark plugs may wear out and need replacing to ensure proper ignition. Also, keeping the fuel system clean prevents clogs and ensures that fuel flows properly to all necessary components.