In the world of automotive repair and maintenance, having a clear understanding of the various components and how they fit together is essential for effective troubleshooting and improvements. Whether you’re a mechanic or an enthusiast, recognizing how each part contributes to the overall performance can make a significant difference.

Every vehicle system consists of numerous interrelated elements, each serving a unique purpose. From the major assemblies to the intricate smaller parts, knowing their roles helps in maintaining smooth operation and identifying issues early. This guide will help you visualize the connections and functions of key components within a typical setup.

Detailed exploration of each unit will empower you to recognize potential problems, perform repairs more accurately, and even enhance performance. A deeper understanding will ultimately lead to a more efficient and durable system.

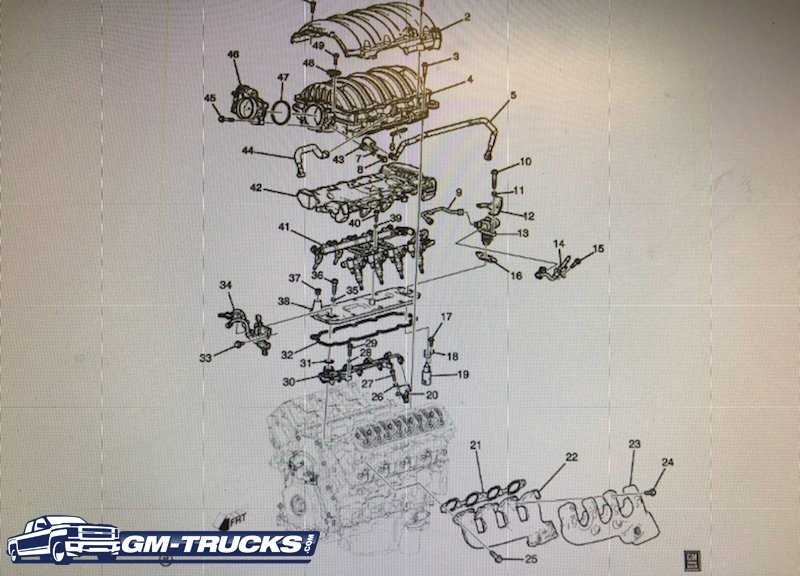

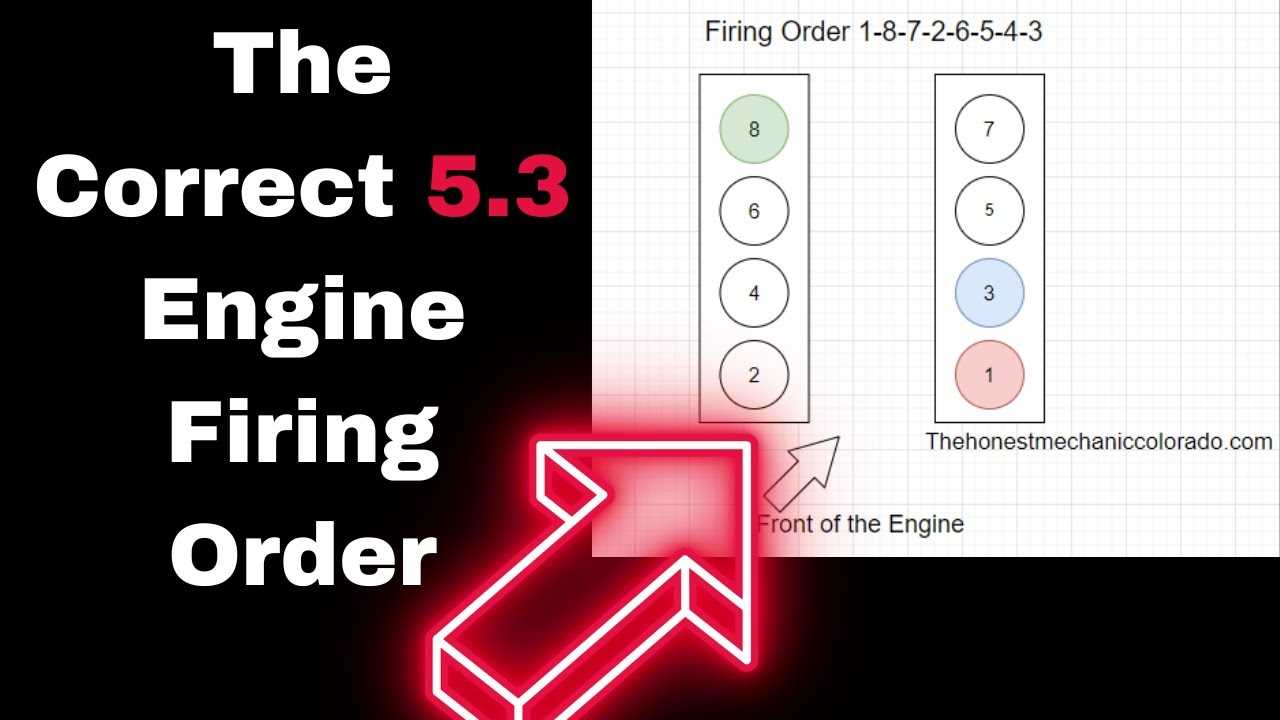

Vortec Engine Components Breakdown

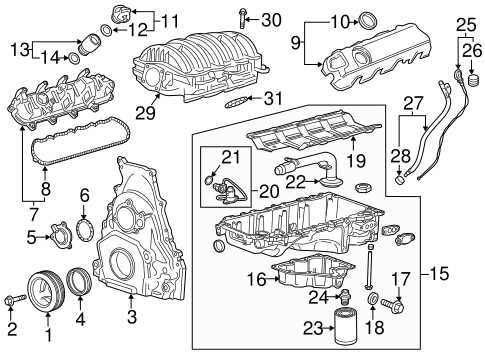

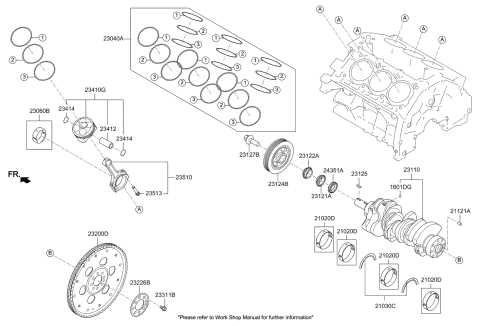

Understanding the key units within an automotive power system is essential for both maintenance and performance optimization. Each assembly plays a vital role in ensuring the vehicle runs efficiently, with the smooth coordination of all the individual components driving the system’s overall functionality.

The core structure consists of several interconnected elements, each designed for a specific task. The combustion chamber, intake, and exhaust systems are crucial in fuel management and power generation. Meanwhile, the lubrication system ensures the smooth operation of moving parts, while the cooling system regulates temperature to prevent overheating. Every section is vital for achieving the balance needed for effective operation.

By examining each assembly closely, one can better understand how they interact and depend on one another. Whether for routine maintenance or troubleshooting, recognizing the distinct functions of each unit allows for faster repairs and better performance management.

Understanding the Key Engine Parts

Every automotive system consists of a variety of components that work together to ensure smooth operation. The primary units involved in generating and controlling power are fundamental for maintaining performance and efficiency. Understanding how these elements interact is crucial for both repairs and optimizations.

At the heart of any power unit are the major assemblies responsible for fuel intake, combustion, and exhaust expulsion. Supporting systems, such as lubrication and cooling, play an equally important role in keeping everything functioning correctly. When these components are properly maintained, the vehicle runs efficiently, delivering optimal power while minimizing wear and tear.

Each part, no matter how small, contributes to the overall functioning of the system. By knowing the specific role of each assembly, you can diagnose issues more effectively and perform precise repairs when needed. This section will help you identify the core units and understand their interconnected functions.

How to Read the Vortec Diagram

Interpreting the schematic of a mechanical system is crucial for understanding the layout and function of its components. These visual representations serve as blueprints, providing insight into how each unit connects and operates within the larger structure. Familiarity with the symbols and lines used can significantly enhance your ability to troubleshoot or perform repairs efficiently.

When examining a schematic, focus on the main sections that correspond to essential functions, such as power generation, fuel delivery, and exhaust. Pay attention to the directional arrows that indicate the flow of fluids or gases, as these guide the process of combustion and energy conversion. Additionally, the connections between components are highlighted, which is essential for diagnosing issues or planning maintenance.

By mastering the ability to read these visuals, you can pinpoint exact areas that may require attention, whether it’s a specific unit that needs replacement or a malfunctioning connection that needs repair. With this knowledge, you can better understand the system’s design and identify potential problems before they become critical.