Understanding the internal structure of a heavy-duty machine is essential for proper maintenance and efficient operation. Knowing the individual elements that contribute to the system’s performance allows for effective troubleshooting, repairs, and upgrades. This guide provides a clear breakdown of the key components involved in the complex machinery, helping both new and experienced operators grasp the configuration and functions of each part.

Main Components Breakdown

Every machine operates with a set of interconnected systems, each performing a specific role. These systems work together to ensure smooth operation and optimal performance. A detailed layout of the primary elements allows for better diagnostics and repair strategies. Here are the most essential elements:

- Fuel Delivery System: Transports and injects fuel into the combustion chamber for ignition.

- Cooling System: Regulates temperature to prevent overheating and maintain safe operating conditions.

- Lubrication System: Ensures smooth movement of parts by reducing friction and wear.

- Electrical System: Powers all electronic controls and components, including sensors and wiring.

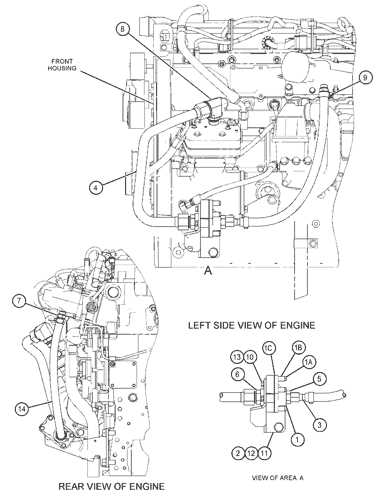

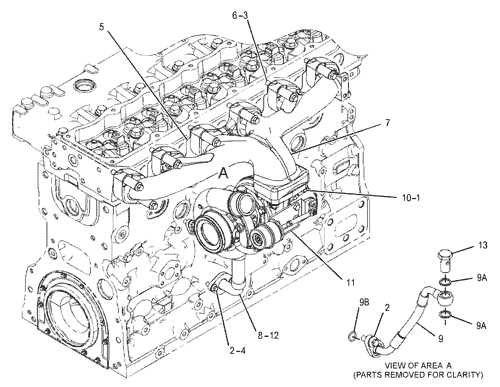

Interpreting the Layout

Having a visual guide helps to quickly identify each component and understand its connection within the broader system. By referring to a schematic or layout, operators can pinpoint the exact location of any malfunction and easily find the corresponding parts for replacement or inspection. A well-detailed chart of the layout assists in streamlining the repair process.

Common Issues and Solutions

Frequent malfunctions are often related to wear and tear, improper maintenance, or incorrect usage. Understanding how to diagnose and address these issues is crucial for keeping the equipment in top condition. Some common problems include:

- Clogged fuel filters: Can lead to fuel delivery issues and engine misfire.

- Cooling system failure: May result in overheating and, if not addressed, could cause permanent damage.

- Worn-out seals: Lead to oil leaks and reduced efficiency in the lubrication system.

By regularly checking these critical elements and ensuring their proper functioning, operators can extend the life of the equipment and reduce costly downtime.

Understanding the Powertrain Mechanism and Key Components

To achieve optimal performance from any complex machinery, understanding the fundamental systems and elements that make it work is crucial. A comprehensive look at how each part operates and interacts with others can greatly enhance efficiency and longevity. Knowing how to read detailed representations of these systems can also assist with diagnosing issues and streamlining repairs.

Key Parts of the Power System

The power mechanism relies on various interconnected parts that work in harmony to drive performance. Each component plays a vital role in ensuring the smooth operation of the system, including:

- Fuel System: Transports and regulates fuel flow for combustion.

- Cooling Mechanism: Keeps the system within safe temperature limits to avoid overheating.

- Lubrication Mechanism: Reduces friction and ensures efficient movement between parts.

- Electrical Components: Provides power to sensors, control units, and other essential elements.

Breaking Down the Structure

Analyzing the layout of a system allows for easier identification and management of issues. By looking at how each section connects to others, operators can quickly detect potential failures or weaknesses in the setup. A well-detailed representation helps in making informed decisions during maintenance and repairs.

Interpreting Schematic Views enables a clearer understanding of how to identify malfunctioning areas. A visual guide highlights each section’s location and relation to the overall system, making troubleshooting and parts replacement more efficient.

Common Malfunctions and Maintenance Tips

Over time, wear and tear may cause issues with the parts that make up the system. Some common problems include:

- Clogged fuel pathways: Can lead to fuel starvation, causing power loss.

- Overheating: Caused by cooling system failure, leading to potential damage.

- Oil leaks: Result from worn seals, reducing lubrication efficiency and increasing wear.

Regular maintenance and timely repairs can significantly reduce these issues, ensuring continuous performance and minimizing costly downtime.