Every vehicle consists of a complex system of individual elements working together seamlessly to ensure smooth operation. Recognizing how these components interact is essential for both enthusiasts and those seeking to perform maintenance or repairs. The arrangement and functionality of each element play a crucial role in the overall performance and longevity of the machine.

Identifying these essential units allows for a deeper understanding of their specific roles. Whether you’re troubleshooting or simply learning more about the intricate design of your vehicle, knowing where each part fits into the larger structure is invaluable.

Proper knowledge of these systems also aids in diagnosing common issues, pinpointing where problems may arise, and making informed decisions during repairs. Understanding the relationship between each unit is key to maintaining peak performance and preventing costly mistakes down the road.

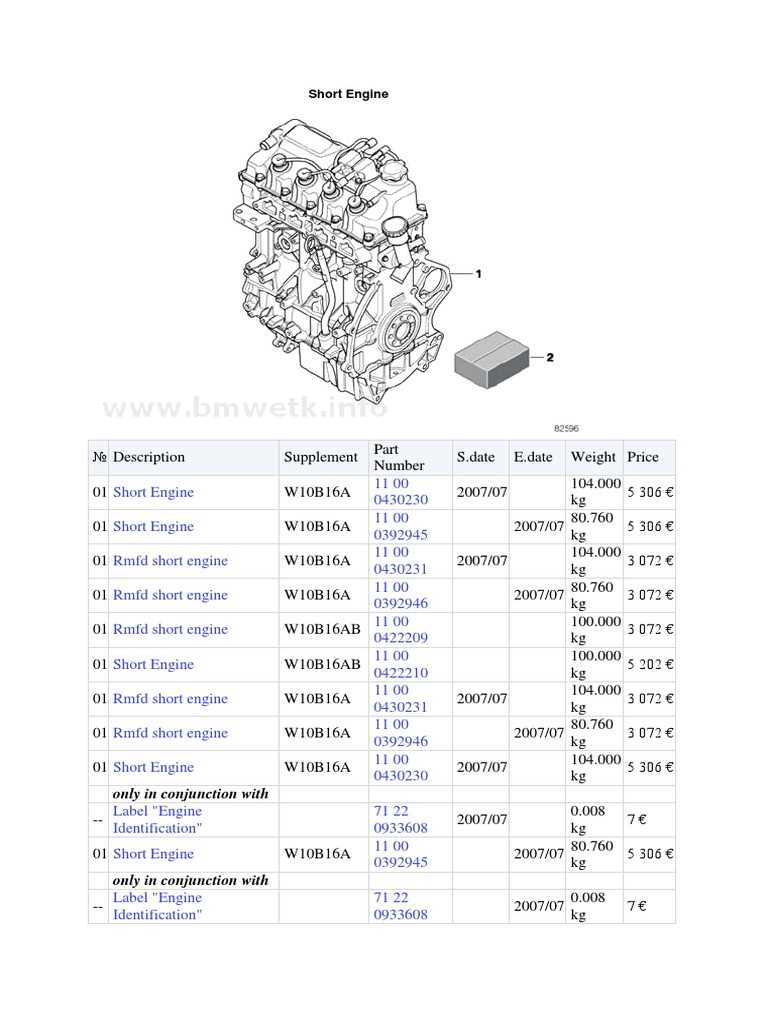

Mini Cooper Engine Overview

In any modern automobile, the internal system responsible for transforming energy into mechanical movement is composed of various intricate elements working in unison. Understanding how these key units interact provides insight into the vehicle’s performance, efficiency, and longevity. A well-coordinated assembly ensures the overall reliability and function, even under demanding conditions.

Key Systems and Their Roles

The core structure involves numerous subsystems such as the fuel supply, air intake, and exhaust processes. These components ensure that the vehicle operates efficiently, providing optimal power output while maintaining fuel economy. Each unit has its dedicated function, from ensuring smooth fuel combustion to regulating airflow for improved engine response.

Maintenance and Care

Proper upkeep of the critical units in the system prevents premature wear and ensures sustained performance. Regular inspection of key components, such as the fuel injectors, cooling system, and sensors, is vital. Keeping these elements in good working order can significantly extend the lifespan of the entire assembly, reducing the risk of costly repairs and unexpected breakdowns.

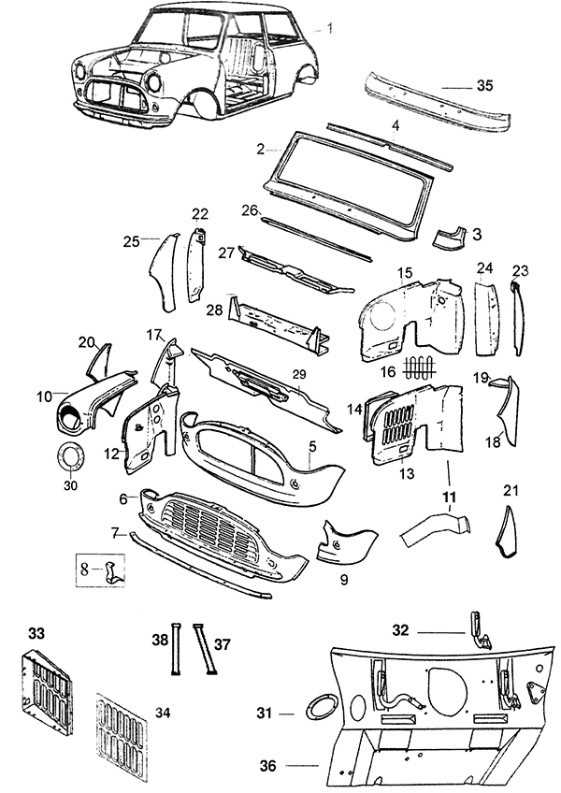

Key Components and Their Functions

Each vehicle relies on a set of vital elements that work together to facilitate movement and maintain smooth operation. These individual units perform specific tasks that contribute to the overall performance, efficiency, and reliability of the machine. Understanding their roles is crucial for anyone interested in maintaining or repairing the vehicle.

Fuel and Air Delivery Systems

The components responsible for the intake of air and fuel are critical in regulating combustion efficiency. The air intake system ensures that clean air flows into the combustion chamber, while the fuel delivery system ensures the correct amount of fuel reaches the engine for optimal performance. Proper coordination between these systems leads to effective combustion and energy production.

Cooling and Exhaust Mechanisms

Effective temperature control is essential to prevent overheating and ensure safe operation. The cooling system, which includes the radiator and thermostat, regulates heat levels. At the same time, the exhaust system channels waste gases away from the engine, minimizing harmful emissions while improving overall efficiency. Both systems play an integral role in maintaining safe operating conditions and performance.

Understanding Engine Assembly Layout

The arrangement of critical components within a vehicle’s power unit follows a precise layout that ensures the optimal functioning of all systems. Each part has a designated position to facilitate efficient energy transfer, temperature regulation, and overall performance. Understanding this structure allows for better maintenance and troubleshooting by providing insight into how each unit supports the others.

Central Components in the Layout

At the heart of the layout are the following key components:

- Fuel System: Ensures the proper delivery of fuel to support combustion.

- Air Intake: Regulates airflow into the system for efficient fuel combustion.

- Cooling System: Maintains optimal operating temperatures by dissipating heat.

- Exhaust System: Channels waste gases out of the unit to reduce emissions.

Interaction and Efficiency

The proper interaction between these core elements maximizes efficiency. The layout is designed to ensure smooth energy conversion while minimizing fuel consumption and harmful emissions. Each system works in harmony, with temperature control mechanisms, air-fuel mixtures, and waste expulsion working together to optimize performance and longevity.

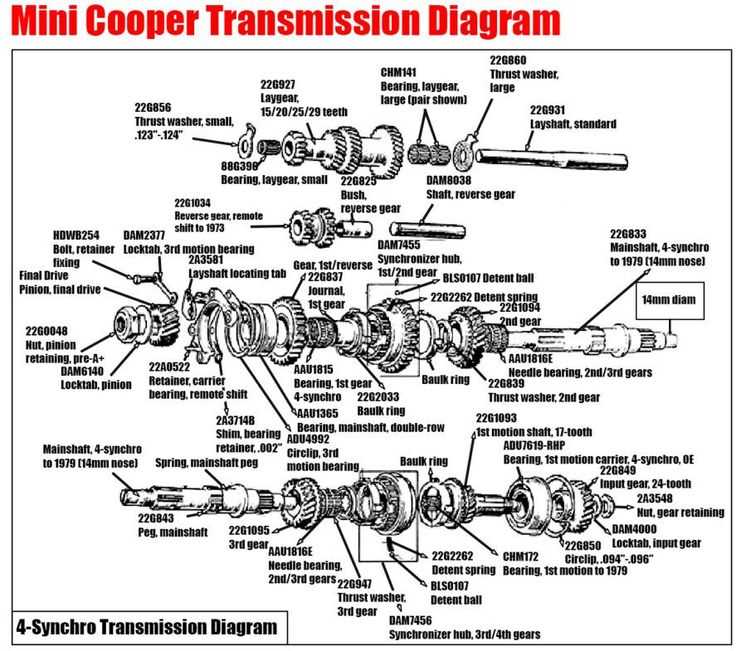

How Parts Work Together Efficiently

The success of any mechanical system lies in how its individual units collaborate to achieve a common goal. Efficient operation depends on the seamless interaction between key elements, ensuring that energy flows smoothly from one process to another. Proper coordination of these components helps optimize overall performance, reduce waste, and enhance reliability.

Interdependency of Systems

Each subsystem relies on the others to function correctly. For instance, the fuel delivery mechanism relies on precise air intake to ensure the correct air-fuel mixture. In turn, the cooling system works to maintain the optimal temperature for both fuel combustion and power generation. This interdependent structure ensures that all systems work in harmony, allowing for balanced operation under various conditions.

Optimizing Performance and Reducing Wear

Efficient interaction also plays a significant role in minimizing wear and tear. When each unit operates within its designed parameters and supports the others as intended, the entire system runs smoothly, which reduces the likelihood of mechanical failure. Regular maintenance and proper calibration of these systems ensure that they continue to function optimally, enhancing the lifespan and performance of the vehicle.

Common Issues with Engine Parts

Over time, the individual components within a mechanical system can experience wear and tear, leading to a range of potential issues that affect overall performance. Identifying these common problems early on can help prevent costly repairs and ensure the longevity of the vehicle. Understanding how each element may malfunction is key to effective troubleshooting and maintenance.

One of the most frequent concerns involves issues with the fuel delivery system, which can lead to poor combustion efficiency. This may manifest as sluggish acceleration or reduced power. Additionally, improper air intake can result in inefficient fuel consumption, affecting both performance and fuel economy. Cooling system malfunctions can also lead to overheating, causing severe damage if left unaddressed.

Another common issue is related to the exhaust system, where blockages or leaks may cause the buildup of harmful gases, impacting both performance and emissions. Regular inspection and maintenance of these critical elements can prevent such problems and help keep the vehicle running smoothly.