Every complex machine relies on a variety of interconnected components, each playing a crucial role in ensuring optimal performance. Whether you’re troubleshooting, performing maintenance, or upgrading, it’s essential to have a clear understanding of how each part functions and fits into the whole system.

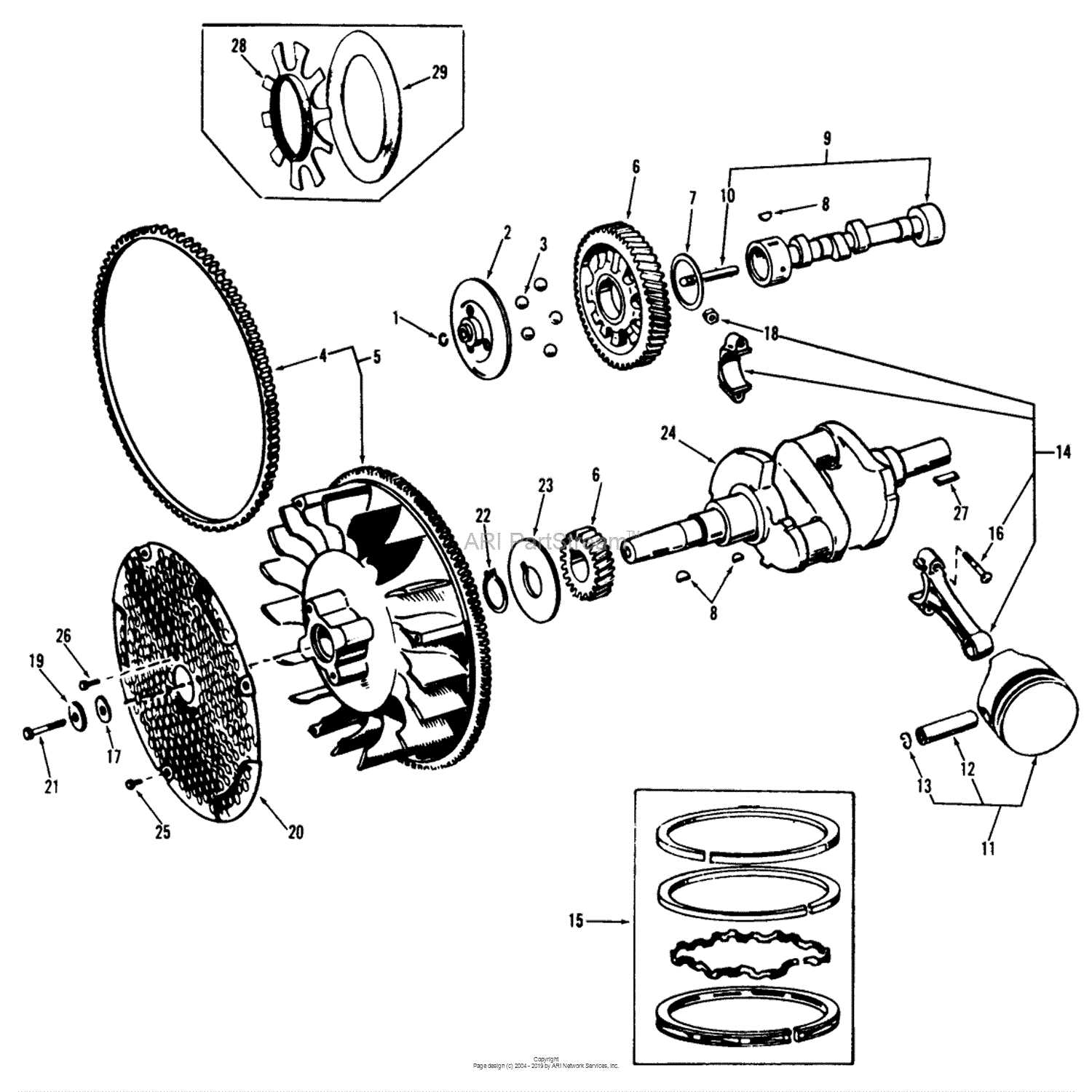

Identifying specific components and knowing their exact location can greatly simplify repairs and maintenance. A detailed visual representation can serve as an invaluable tool for both novice and experienced users, allowing them to efficiently navigate the intricacies of the system.

By examining these detailed representations, you can easily pinpoint issues, prevent common malfunctions, and ensure the longevity of your equipment. Understanding how each individual piece works together is the first step toward mastering the repair and maintenance process.

Understanding Onan Engine Components

To maintain and repair complex machinery, it’s essential to have a clear grasp of the various elements that make up the system. Each component has a unique function, but when combined, they work in harmony to ensure the equipment operates efficiently and reliably. Recognizing these components and understanding how they interconnect can significantly simplify troubleshooting and maintenance tasks.

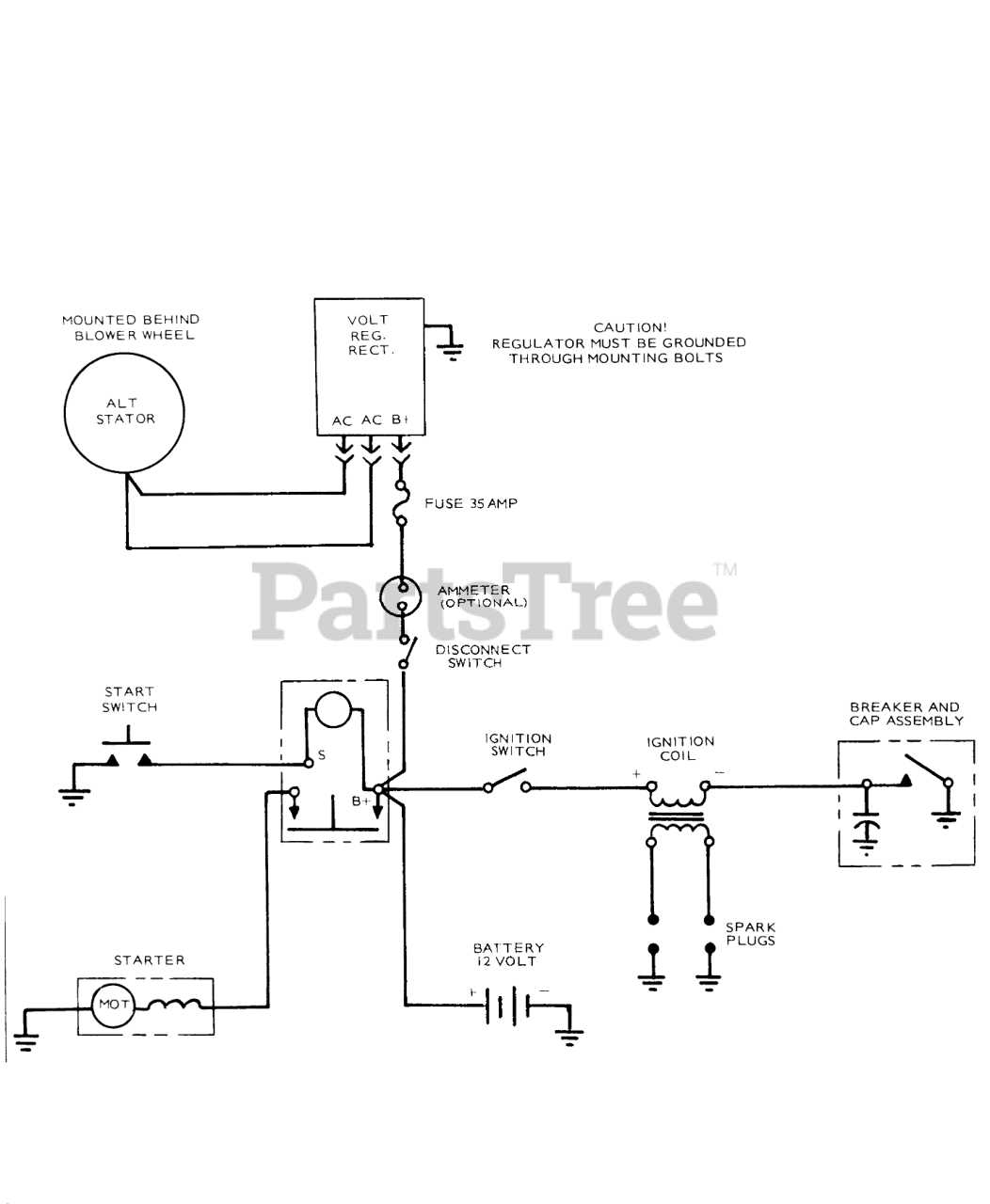

Identifying key elements such as the ignition system, fuel delivery, and exhaust components is the first step in diagnosing any issues. Each part serves a specific role in powering the system, and knowing how they interact is crucial for effective repairs.

Maintenance of these crucial components involves regular inspection and timely replacement of worn-out parts. Understanding their structure and function helps identify potential weak spots before they lead to serious damage, ultimately saving time and costs in the long run.

How to Read Onan Engine Diagrams

Understanding visual representations of mechanical systems is a critical skill when it comes to diagnosing issues or performing maintenance. These illustrations offer a detailed map of how various components are arranged and how they interact. Knowing how to interpret these visuals can save time and reduce the complexity of repairs.

Start by familiarizing yourself with the symbols and labels used to represent different parts. Often, these diagrams include a combination of lines, shapes, and annotations that correspond to real-world components. Pay attention to the layout, as it shows the physical relationship between each element, helping you visualize how the system functions as a whole.

It’s also important to understand the flow paths shown in these illustrations. Whether it’s the path of fluids, electrical circuits, or mechanical movements, the diagrams often indicate the direction in which each element operates. By following these paths, you can quickly identify areas where issues may arise and where intervention is needed.

Common Issues in Onan Engines and Fixes

Machines often face a variety of challenges that can impact their overall performance. Identifying these common issues early can prevent further damage and ensure the system runs efficiently. From fuel supply problems to electrical malfunctions, understanding the most frequent causes of trouble can help in applying the right solutions.

Fuel and Ignition Problems

One of the most common issues is a disruption in the fuel or ignition system. Problems like clogged fuel filters, faulty spark plugs, or improper fuel delivery can cause the equipment to run poorly or fail to start. Regularly checking the fuel system and replacing old filters or plugs can resolve many of these issues.

Electrical and Overheating Issues

Electrical failures, such as dead batteries or damaged wiring, are also frequent culprits behind equipment malfunctions. Overheating due to inadequate airflow or worn-out cooling components is another issue that can impair performance. Ensure proper maintenance of the electrical system and cooling components to avoid these problems.