Understanding the various components of a well-functioning piece of equipment is essential for efficient performance and maintenance. Every element plays a crucial role in the overall functionality, ensuring that the system operates smoothly. From the smallest parts to the larger assemblies, the precise arrangement of components is what keeps everything in harmony.

Keeping these components organized allows for quick repairs and minimal downtime, contributing to a seamless experience. Recognizing how these parts interact with one another ensures that users can handle common issues and improve the longevity of their equipment.

Understanding the Components of Snapper Mowers

Every machine consists of multiple interconnected elements, each fulfilling a specific function that contributes to its overall operation. Recognizing the key components within your equipment allows for more efficient troubleshooting and maintenance. These crucial elements range from the power source to the mechanisms responsible for motion and control.

When you understand how each part interacts with others, it becomes easier to diagnose any issues and perform necessary repairs. Whether it’s the drive system or the cutting mechanism, knowing their structure and role helps maintain smooth performance for an extended period.

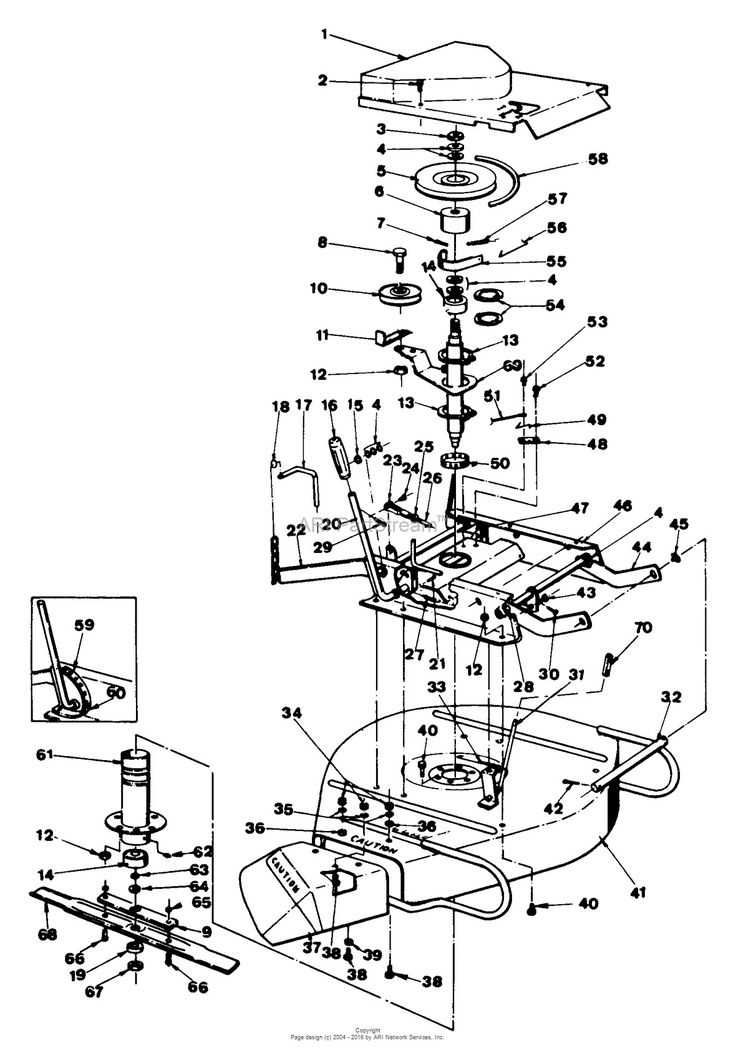

How to Use the Parts Diagram Effectively

Having a visual reference is essential when working with machinery, as it helps users identify and locate individual components with precision. A well-structured illustration allows you to see how each part fits into the overall system and assists in understanding its function. This makes the process of repair or maintenance more straightforward and less time-consuming.

Step-by-Step Approach

Start by locating the section relevant to the issue you’re addressing. Carefully study each part, noting any differences in design or position compared to similar components. Focusing on key areas helps pinpoint where potential problems might lie. Pay attention to connecting pieces, as small misalignments can affect overall performance.

Tips for Accurate Troubleshooting

Use the illustration as a guide while inspecting your equipment. If you need to replace a component, compare the damaged part with the image to ensure compatibility. This reduces the chances of purchasing the wrong item and saves time during repairs.

Common Issues and Fixes for Rear Engine Mowers

Machines designed for lawn care often encounter specific issues due to wear and tear, improper usage, or lack of maintenance. Identifying these common problems early can save time and prevent costly repairs. Regularly checking for wear or damage is essential to keep your equipment running smoothly.

Starting Problems

One of the most frequent issues is difficulty starting the system. This could be caused by a faulty battery, clogged fuel lines, or an air filter that is dirty. If the power source isn’t delivering sufficient charge, the first step is to inspect the battery for signs of corrosion or leakage. Ensure all fuel lines are clear and check if the spark plug is clean and functional.

Uneven Cutting or Poor Performance

Another common concern is uneven cutting or poor overall performance. This can stem from dull blades, improper tire pressure, or an unbalanced cutting deck. Regularly sharpening the blades and checking tire inflation can significantly improve the quality of the cut. Balance the cutting deck to ensure even distribution of weight for optimal results.