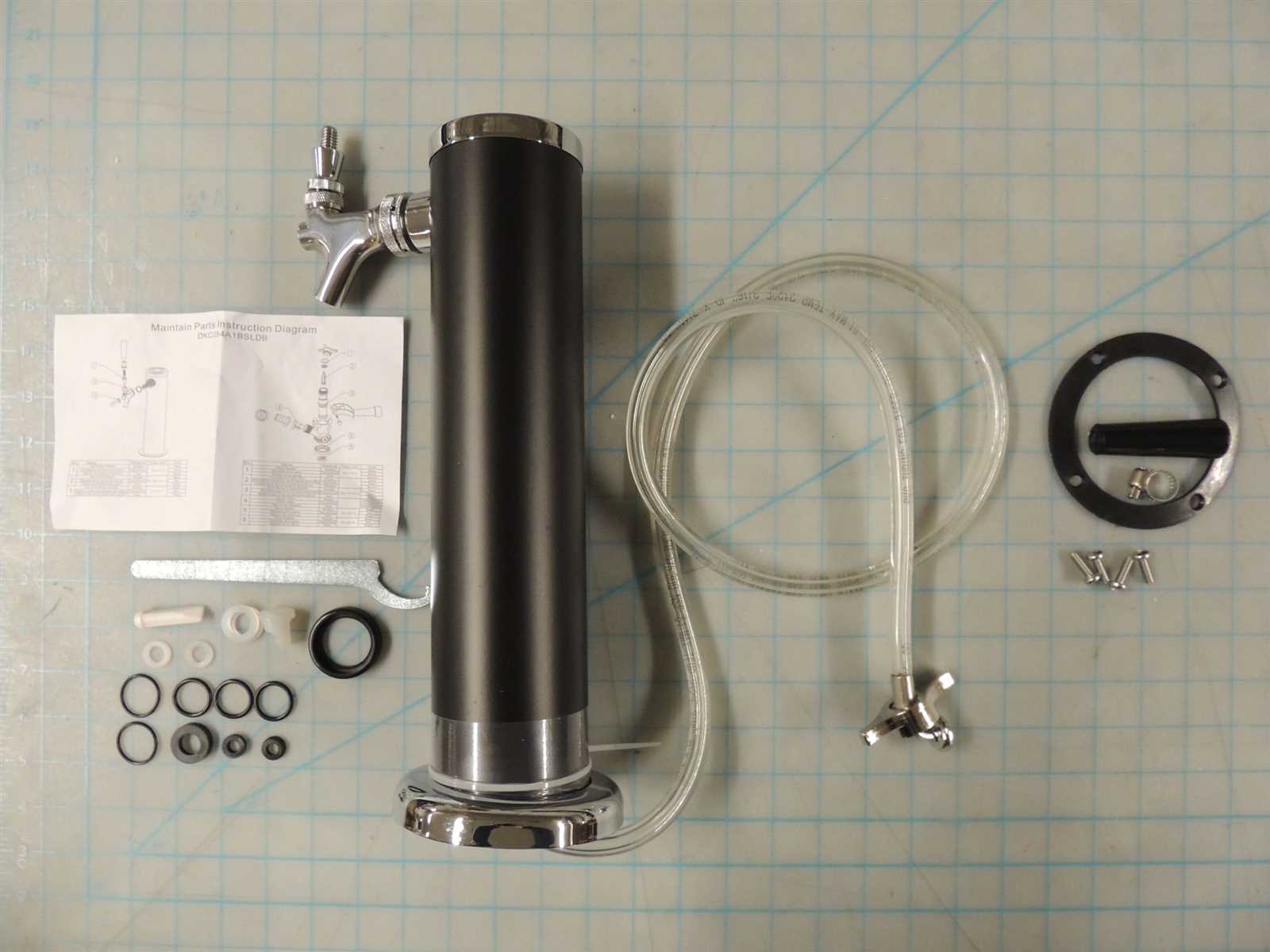

Every dispensing system relies on a series of interconnected components that ensure smooth and efficient operation. These systems, whether for beverages or other liquids, require precise assembly and maintenance to function optimally. Understanding the roles of each element can help in troubleshooting, cleaning, and upgrading your setup.

The various elements work together to control flow, pressure, and consistency, making it crucial to know how they fit into the larger mechanism. Each piece has its own function, but when combined, they contribute to a seamless experience for both the user and the machine. Proper knowledge of these components can extend the lifespan of the entire system.

In this guide, we will explore the key elements involved in the dispensing process, offering a clear breakdown of their functions and how they interact. With a deeper understanding, you can ensure your equipment stays in top condition, preventing potential issues and improving overall performance.

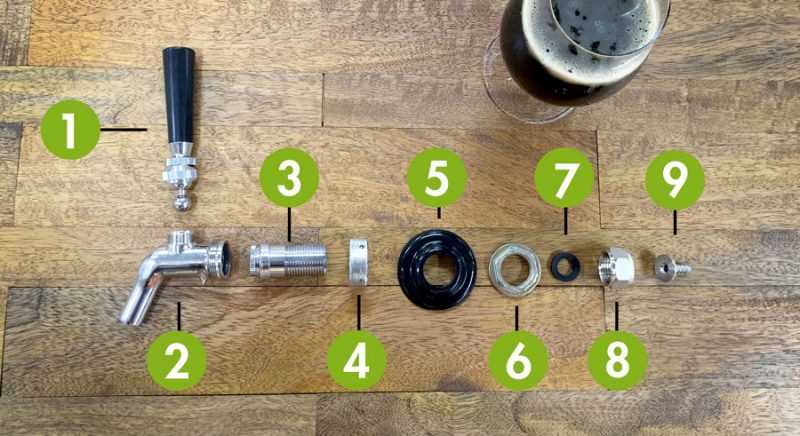

Understanding Beer Faucet Components

In any liquid dispensing system, the efficiency and functionality depend on a variety of crucial elements working in harmony. These components are designed to control the flow, pressure, and temperature of the liquid, ensuring a consistent and smooth delivery. Each part serves a specific purpose, contributing to the overall operation of the system. Understanding these individual elements is essential for proper setup, maintenance, and troubleshooting.

The central mechanism that regulates the flow of the beverage involves several interconnected pieces. These components include mechanisms for controlling pressure, as well as those that manage temperature and volume. When assembled correctly, these pieces allow for an optimal dispensing experience, whether in a home setup or commercial environment. Knowing how these elements function together will help ensure your system operates at peak efficiency.

Proper maintenance of these components is also critical. Regular cleaning and occasional replacements of worn-out parts can prevent malfunctions, ensuring long-term performance. Recognizing the key components and understanding their roles allows for easier diagnostics and more effective care of your dispensing system.

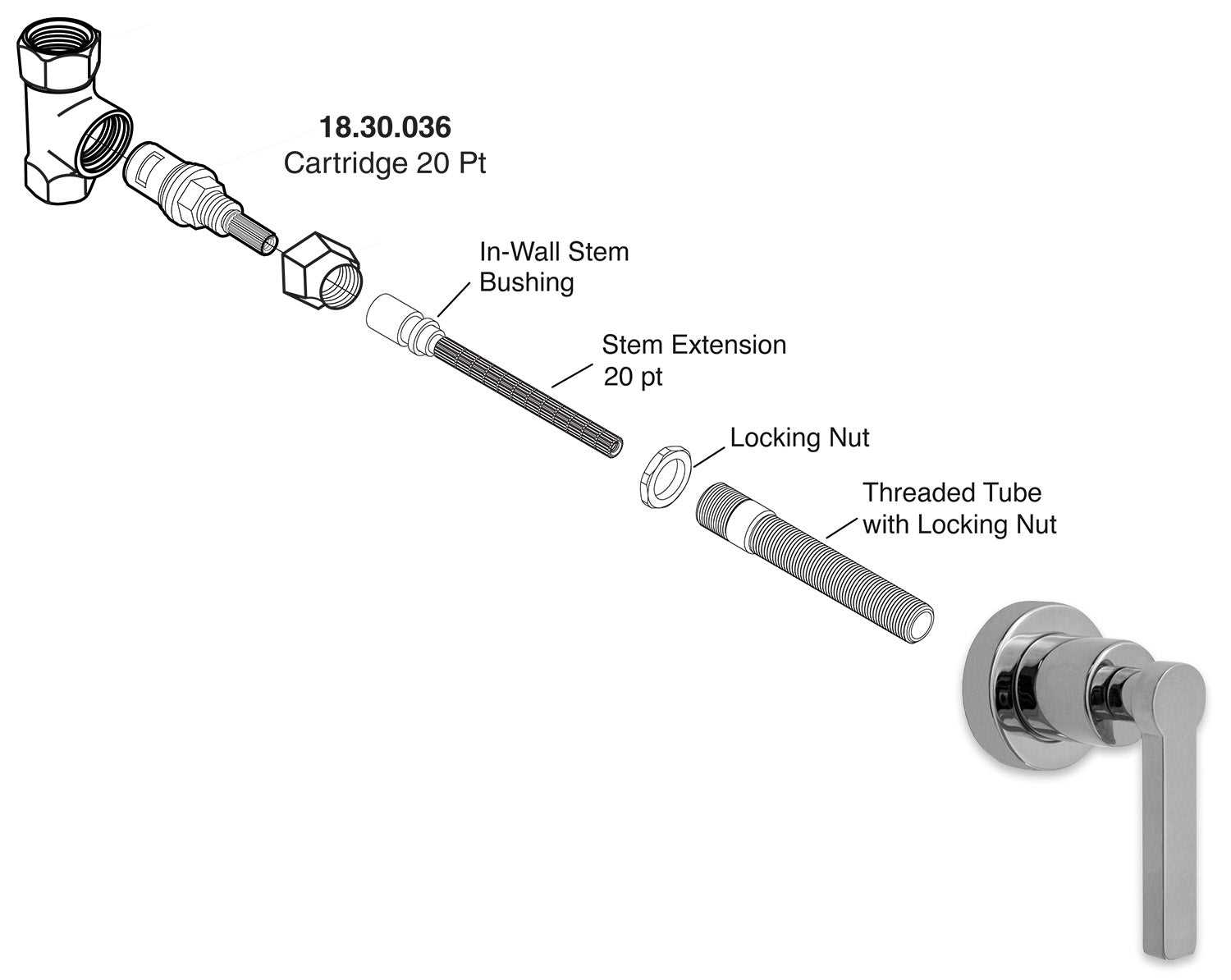

How to Identify Key Faucet Parts

Recognizing the essential components of a dispensing system is the first step toward effective maintenance and troubleshooting. By becoming familiar with the main elements involved, you can easily identify which part might be causing an issue, whether it’s a blockage, leak, or inconsistent flow. Each component has a unique function, and understanding these roles will help you spot them with ease.

The most important elements to identify include the control mechanism, the sealing components, and the flow regulators. These are typically the first areas to check when diagnosing performance problems. The control mechanism allows you to adjust the flow, while sealing components prevent leaks and ensure pressure consistency. Flow regulators are crucial for managing the speed and volume of the liquid being dispensed.

Once you know where each component is located and what it does, it becomes much easier to maintain or replace the necessary parts when needed. Whether you’re dealing with wear and tear or performing routine upkeep, knowing how to identify these key elements will save time and effort in the long run.

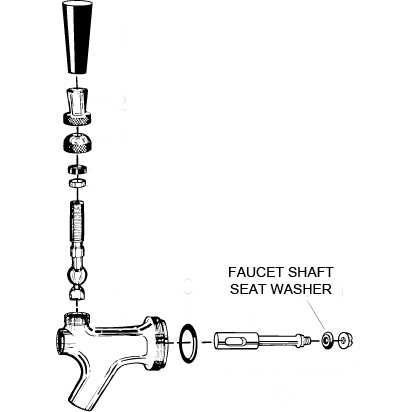

Maintaining Your Beer Faucet System

Regular upkeep of your liquid dispensing system is essential for ensuring consistent performance and longevity. A well-maintained setup not only prevents operational failures but also ensures that the quality of the dispensed product remains high. Routine cleaning, inspecting for wear, and addressing issues promptly can save you time and money in the future.

Routine Cleaning and Sanitizing

One of the most important aspects of maintaining your dispensing system is regular cleaning. Over time, residues can accumulate, affecting both the taste and efficiency of the flow. It is crucial to clean the internal components thoroughly to prevent the buildup of grime or bacteria. Ensure that all accessible parts are sanitized, particularly the areas in direct contact with the liquid. Follow the manufacturer’s guidelines for cleaning intervals and procedures to avoid damaging any sensitive components.

Inspecting and Replacing Worn Components

Another key part of maintaining your system is inspecting for wear and tear. Seals, gaskets, and other moving components can degrade over time due to constant use. Check for any cracks, leaks, or signs of friction that could interfere with smooth operation. Replacing worn-out components promptly will help prevent more serious issues and maintain a steady, trouble-free flow.