Commercial plumbing systems are made up of several essential components that work together to ensure smooth operation. Knowing how these elements function and how they are interconnected is crucial for proper maintenance and repair. In this section, we will explore the various parts and their roles in the functionality of plumbing systems used in restaurants, kitchens, and other high-traffic environments.

Key Elements of Plumbing Systems

The basic structure of a plumbing fixture includes several main pieces that control water flow, manage temperature, and prevent leaks. These components are usually designed for durability and high performance in demanding settings. Understanding the design and purpose of each part helps in troubleshooting and repairs.

Main Components

- Handles and Levers: These are used to control water flow and temperature.

- Valves: They regulate the passage of water through the system, ensuring proper pressure and temperature.

- Sprayers: These accessories provide a focused stream of water for specific tasks, such as rinsing dishes or cleaning surfaces.

- Seals and O-Rings: These prevent leaks by creating tight seals between moving parts.

Maintenance and Troubleshooting

Regular maintenance is vital to keep the system functioning efficiently. Over time, parts may wear out or become damaged, leading to leaks or inconsistent performance. Recognizing the signs of malfunction and knowing which components need attention can help in extending the lifespan of the fixture.

Common Problems and Solutions

Some of the most frequent issues encountered with plumbing systems include:

- Leaks: Often caused by worn-out seals, O-rings, or loose connections. Replacing these components can restore proper function.

- Low Water Pressure: A clogged aerator or a malfunctioning valve may be the culprit. Cleaning or replacing these parts can resolve the issue.

- Temperature Control Issues: This could be due to a faulty temperature control valve. Replacing the valve can solve the problem.

By regularly inspecting and replacing key components, you can ensure the system remains in top condition, minimizing downtime and improving performance.

Understanding Plumbing Fixture Components and Their Functionality

Proper knowledge of the components that make up a plumbing fixture system is essential for efficient maintenance and repair. These elements work together to ensure optimal performance, from regulating water flow to preventing leaks. Understanding how to interpret system schematics and identifying each component’s role can save time and effort when addressing issues in commercial settings.

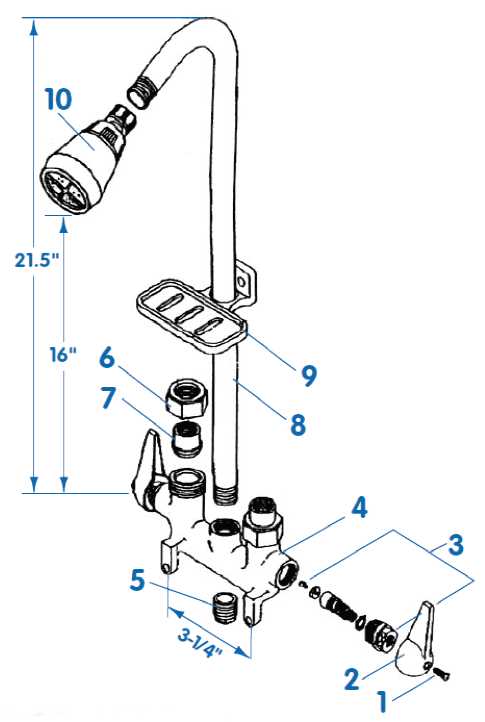

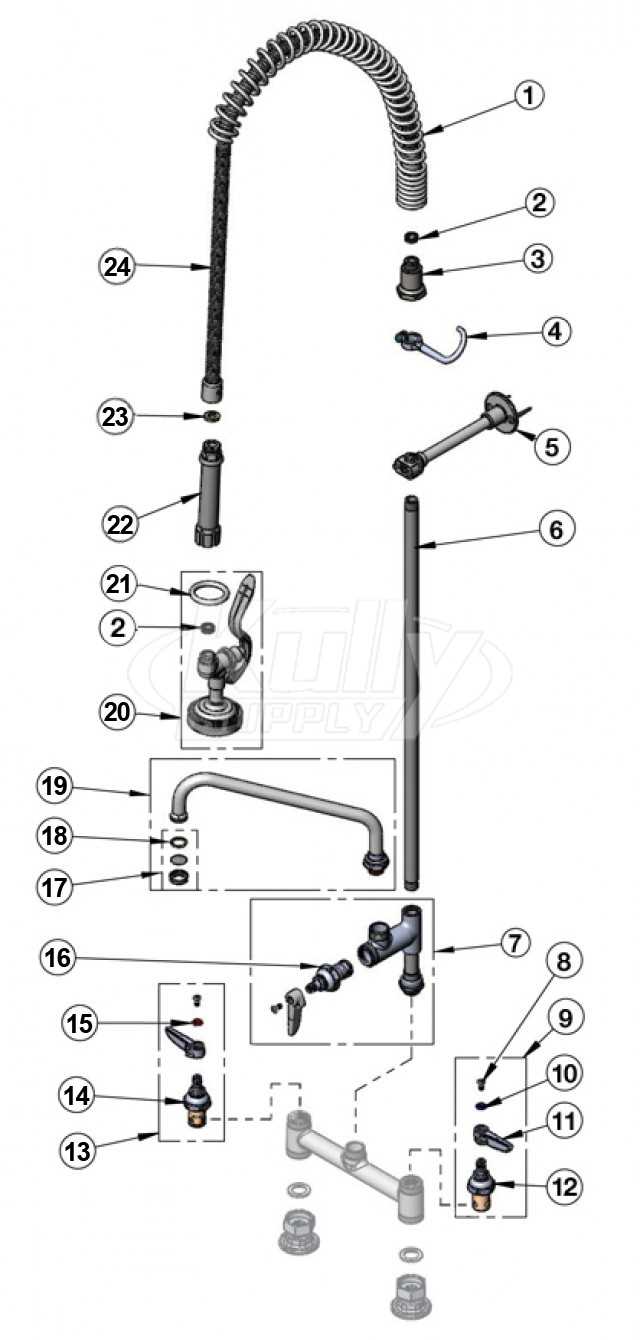

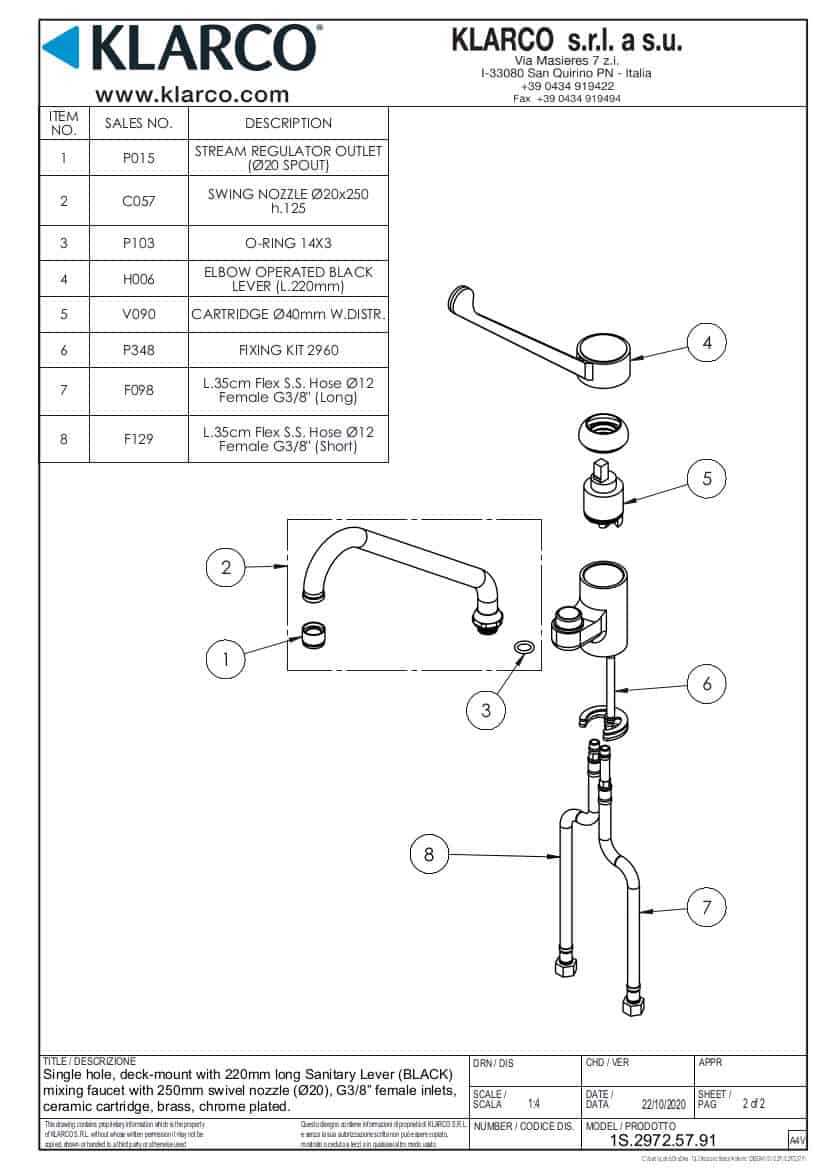

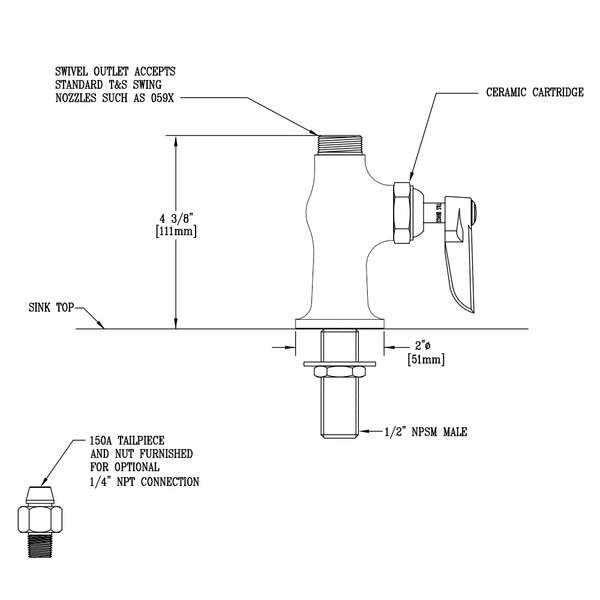

Reading system schematics is crucial for identifying parts and understanding their interconnections. A well-structured schematic offers a clear visualization of each piece’s location and function, making troubleshooting much easier. Recognizing how components interact helps in making informed decisions when replacing or repairing elements within the fixture system.

Some of the essential components in any plumbing setup include control mechanisms, pressure regulators, and seals. These parts work together to maintain consistent water flow and temperature, as well as to prevent unwanted leaks or malfunctions. Familiarity with their placement and function is key for performing repairs quickly and efficiently.

Each fixture contains specific mechanisms that manage water temperature, pressure, and flow. Identifying these components in a diagram allows for accurate diagnosis of issues and speeds up repairs. Knowing which part to target when an issue arises helps prevent unnecessary disassembly or confusion during the troubleshooting process.

Common issues in plumbing systems often stem from worn-out seals, malfunctioning valves, or clogs in the water flow system. Recognizing these problems early can lead to swift resolutions. Solutions often involve replacing or adjusting components, such as seals, valves, or pressure regulators, ensuring the system operates as intended for an extended period.