Every piece of agricultural machinery relies on a network of interconnected elements that work together to ensure smooth operation. Proper understanding of these components can significantly enhance efficiency, reduce wear, and simplify repairs. An organized approach to identifying and maintaining each section of the equipment is key to prolonging its life and optimizing its performance.

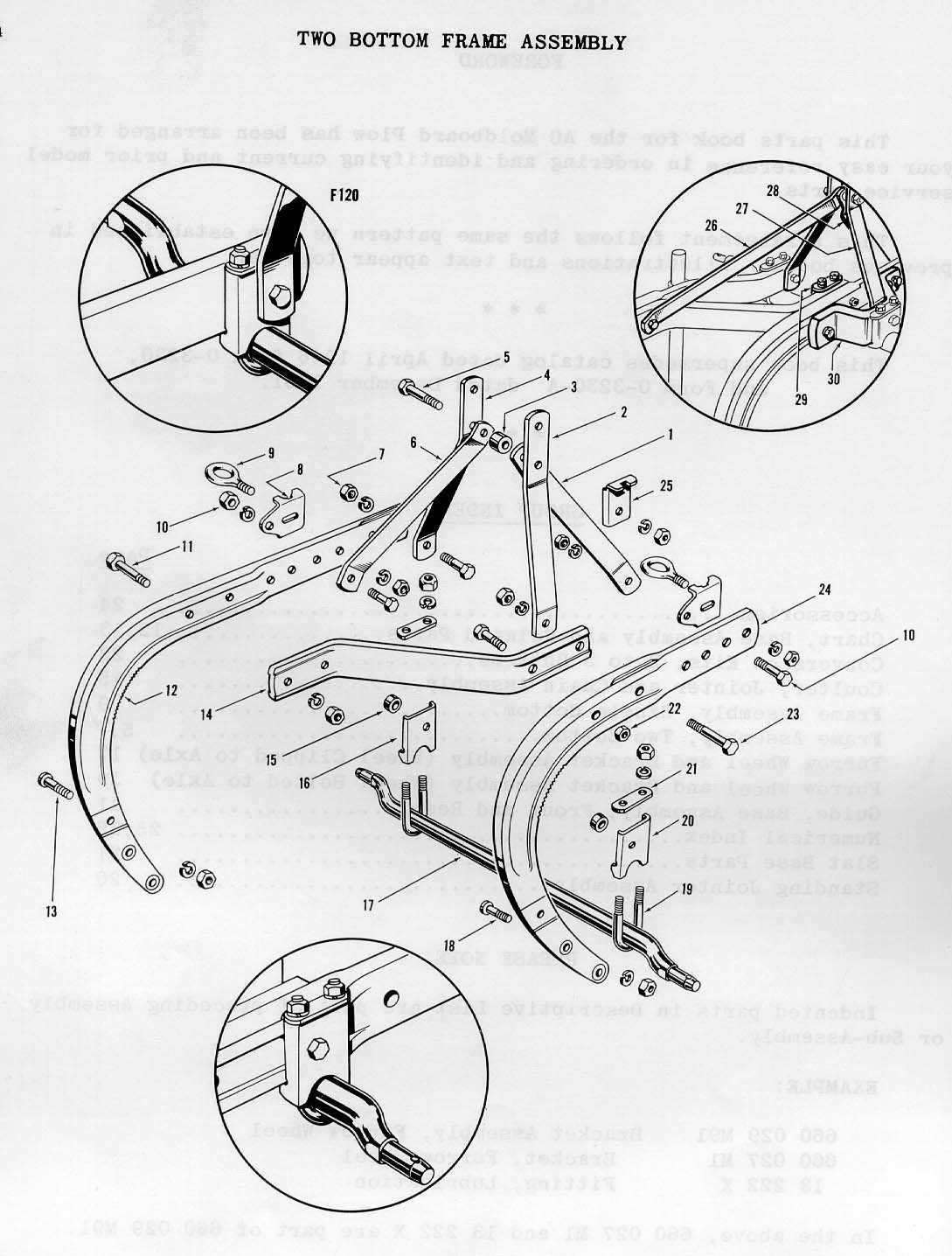

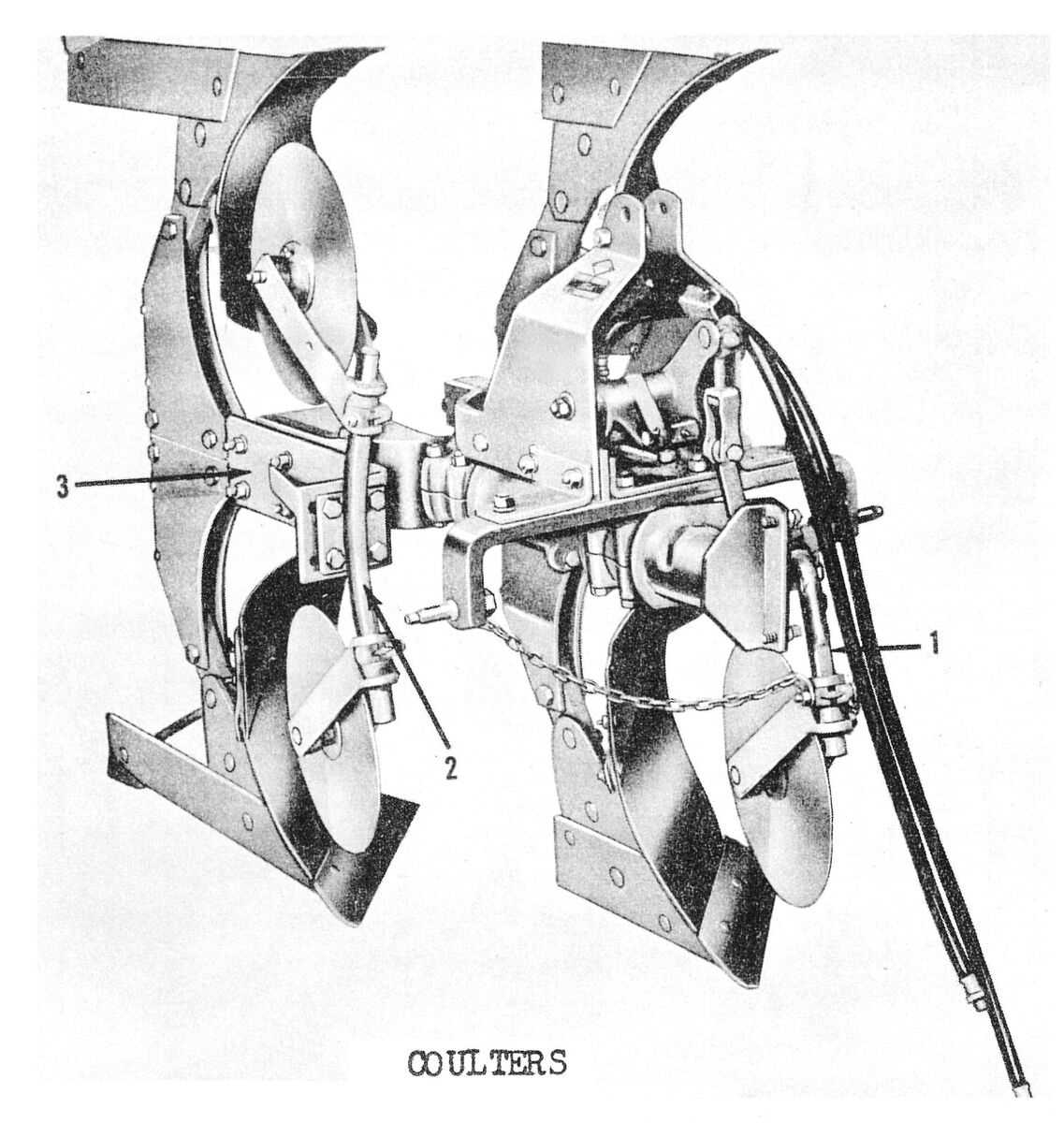

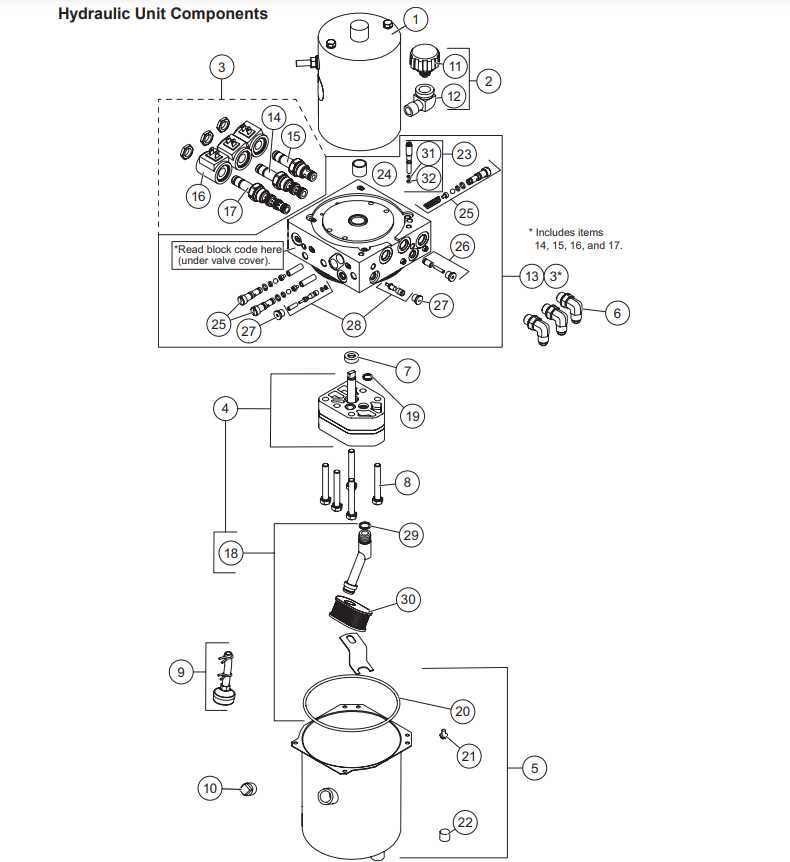

Detailed visual guides can provide valuable insights into how various parts interact with one another, making it easier to troubleshoot and fix issues. A clear overview of these essential elements is crucial for both novice users and experienced operators looking to enhance their knowledge and troubleshooting capabilities.

Understanding the function of each component is not only beneficial for maintenance but also for maximizing productivity in the field. Whether it’s routine upkeep or dealing with a specific malfunction, knowing how each part fits into the larger system is essential for effective management and smooth operation of the equipment.

Understanding the Equipment Components

Every mechanical tool designed for fieldwork consists of various interconnected elements that contribute to its overall performance. These components, whether large or small, are crucial to the proper functioning of the system, each serving a specific role that supports the overall task. Recognizing these parts and understanding how they interact is essential for effective maintenance and efficient operation.

The different sections of the machinery are often labeled to highlight their functions, which allows users to easily identify any issues or areas that require attention. By understanding the purpose of each part, operators can more effectively troubleshoot, replace damaged components, or perform routine checks that enhance the longevity of the equipment.

Properly maintaining each element helps prevent unnecessary wear, ensuring that the machine performs at its best for longer periods. Familiarity with these components also aids in making informed decisions when it comes to repairs, upgrades, or adjustments, leading to increased productivity and a smoother operation overall.

Identifying Key Components in the Visual Guide

When examining any mechanical tool, recognizing the most essential elements is crucial for proper operation and maintenance. By focusing on the primary sections and their unique functions, users can quickly determine which components are most integral to the machinery’s efficiency. This knowledge simplifies the process of troubleshooting and repair, making it easier to identify potential issues before they become significant problems.

Familiarizing yourself with the main components allows you to understand the overall structure and how each part contributes to the machinery’s performance. Key elements are typically highlighted in guides to ensure clear identification, and understanding these features ensures smoother navigation during maintenance tasks. Accurate identification is the first step in ensuring that all components are functioning optimally, allowing for faster and more effective repairs when necessary.

Once the primary parts are identified, it becomes easier to pinpoint areas that require attention. Whether performing regular upkeep or troubleshooting unexpected malfunctions, knowing the key components helps in making informed decisions. By recognizing these elements, users can enhance the equipment’s overall longevity and maintain peak performance throughout its use.

Tips for Maintaining Your Equipment

Regular maintenance is essential for ensuring that any piece of machinery continues to function smoothly and efficiently. By following a few simple practices, users can extend the life of their equipment and avoid costly repairs. Routine checks, proper cleaning, and timely adjustments are all important steps in keeping everything in optimal condition.

Routine Inspections and Adjustments

Performing regular inspections is one of the most effective ways to prevent unexpected malfunctions. Look for any signs of wear or damage, particularly on the critical components that experience the most stress during use. Tightening bolts, lubricating moving parts, and adjusting settings according to manufacturer recommendations can prevent larger issues from arising.

Cleaning and Proper Storage

Keeping your equipment clean is just as important as ensuring it is mechanically sound. Dirt and debris can cause unnecessary strain on various components, so it’s vital to clean all sections thoroughly after use. Additionally, storing the equipment in a dry, sheltered area protects it from rust and other environmental damage, ensuring it remains in working order for the long term.