When it comes to maintaining your machinery, having a clear visual reference of its components is essential for ensuring smooth operation and avoiding costly repairs. Identifying the various elements of a machine helps in troubleshooting and identifying wear or damage early on, ultimately extending the equipment’s lifespan. Knowing how to access and interpret this information is key to effective maintenance.

Detailed schematics offer a clear breakdown of all significant components, allowing for an easier understanding of their connections and functions. These guides are invaluable resources for anyone looking to carry out repairs or perform regular maintenance tasks independently.

With the right tools and knowledge, performing simple repairs becomes manageable, empowering you to take better care of your machinery. Whether you are a seasoned professional or a beginner, this visual aid can make the difference between success and failure when dealing with mechanical issues.

Understanding the Ford 1910 Tractor Parts

Every piece of equipment is made up of various elements, each serving a specific function that contributes to the overall performance and reliability of the machine. In order to maintain and repair this equipment effectively, understanding the role of each component is crucial. Identifying individual sections and understanding their relationship with other parts ensures that all functions are optimized and working in harmony.

Key Components and Their Functions

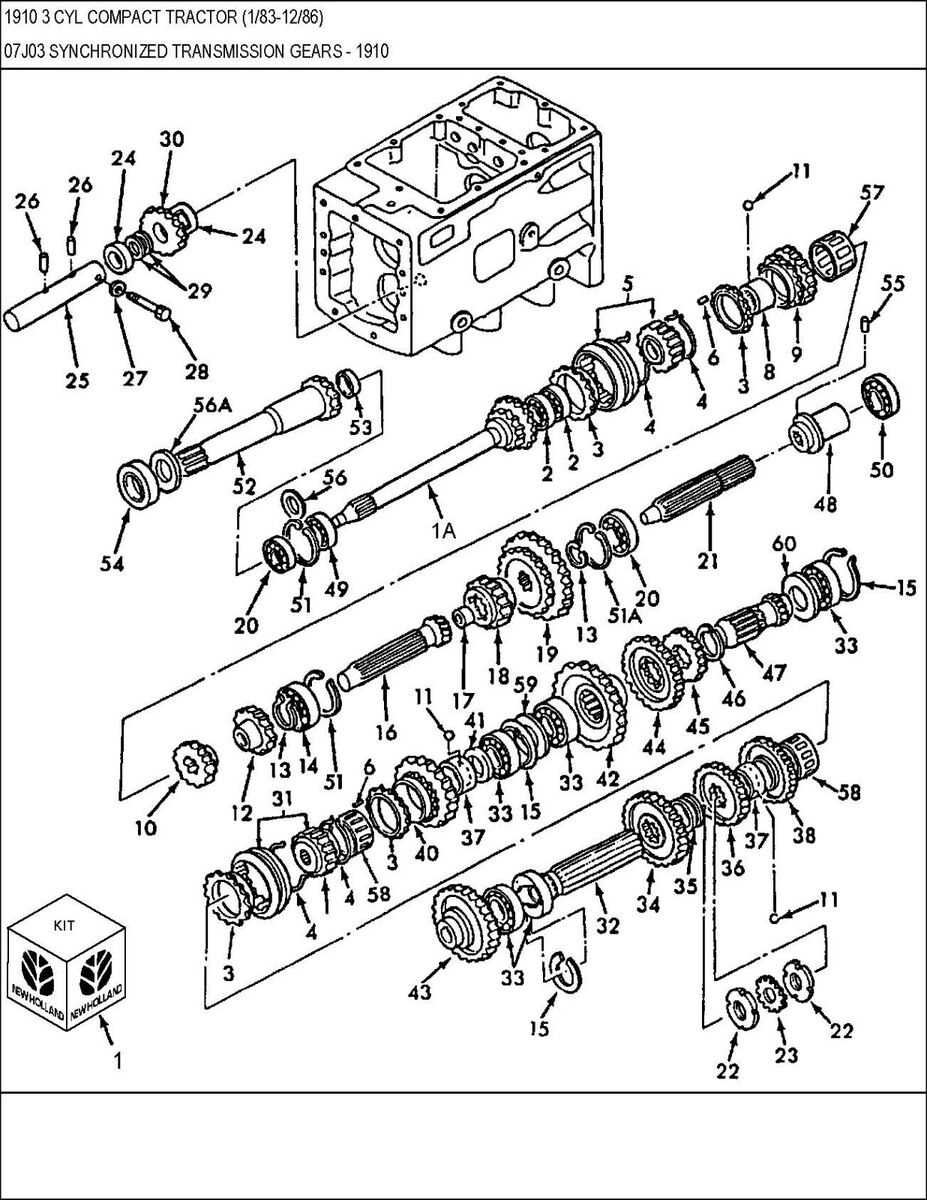

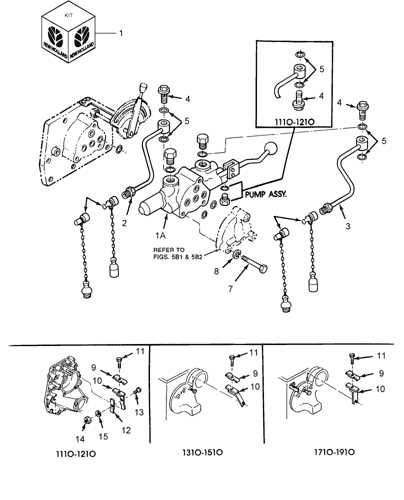

At the core of the system are several critical units that manage power, mobility, and stability. The engine assembly is the heart of any machine, while transmission and axle components are vital for controlling movement. The hydraulic system plays a key role in ensuring that the equipment remains responsive and flexible under different working conditions. Understanding how each unit contributes to the whole allows for better care and quicker fixes when issues arise.

Common Maintenance Areas

While every component has its own importance, certain parts often require more attention due to their frequent use and wear. Regular checks of fuel systems, brakes, and belts can prevent many common issues. Ensuring these high-use components are in good condition extends the life of the entire machine and keeps it running smoothly. Having a detailed reference for these areas helps identify potential problems before they become major repairs.

How to Read the Parts Diagram

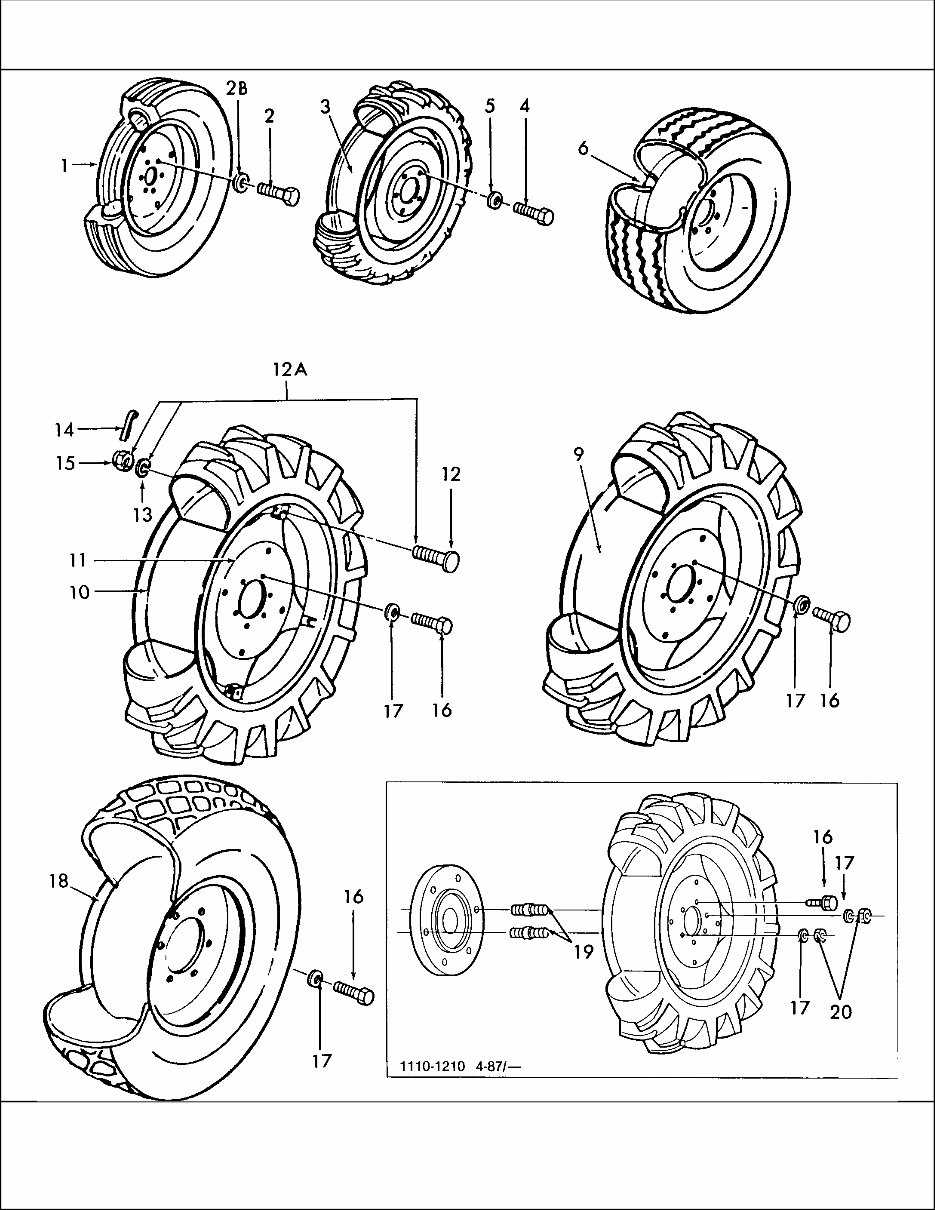

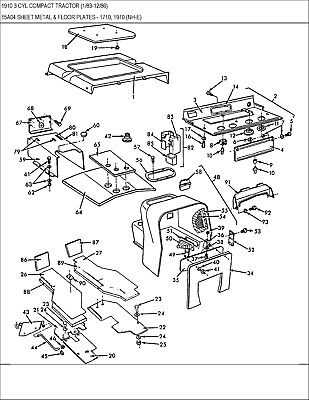

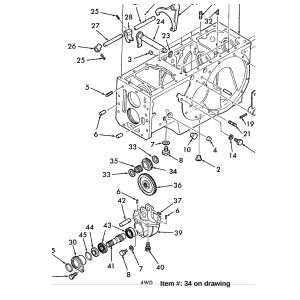

Understanding how to interpret technical schematics is an essential skill for anyone maintaining or repairing machinery. These visual guides break down complex systems into easily recognizable components, allowing users to quickly identify individual elements and their relationships within the entire assembly. Learning how to read these illustrations not only helps in understanding the machine’s structure but also aids in troubleshooting and part replacement.

The first step is to familiarize yourself with the symbols and notations commonly used. Each part is represented by a unique symbol or image, with accompanying labels to indicate their names or functions. These references provide a visual map that correlates directly to the physical components. Additionally, the schematic will often include numbers or codes next to the parts, which can be cross-referenced with a parts catalog for accurate ordering or identification.

Next, pay attention to the layout and connections between components. A good schematic will show how different units are interconnected, whether they operate together or influence one another. By following the flow of lines and arrows, it becomes easier to understand how the system works as a whole and where potential issues may arise.

Common Ford 1910 Tractor Part Replacements

Over time, some components of machinery experience wear and tear, requiring replacement to maintain proper functioning. Regular maintenance and timely replacements can prevent unexpected failures and ensure the equipment continues to perform at its best. Recognizing which parts are most likely to need replacement helps in managing repairs and avoiding downtime during critical work periods.

High-Wear Components

Several components are more susceptible to damage due to frequent use or harsh operating conditions. Items such as belts, hoses, and filters often require replacement after a set period of usage. These parts play essential roles in ensuring smooth operation, and their degradation can lead to performance issues or even complete breakdowns. Monitoring their condition and replacing them regularly can help extend the life of the machine.

Common Mechanical Replacements

Other key mechanical parts, such as bearings, seals, and gaskets, are also commonly replaced as they age. These elements are critical for maintaining proper alignment, preventing leaks, and ensuring efficient power transfer. Regular inspection can catch early signs of damage, allowing for prompt replacement before they cause major issues. Additionally, replacing worn-out mechanical components improves overall system efficiency and reliability.