Maintaining agricultural equipment in optimal working condition requires a deep understanding of its individual elements. Knowing how each component interacts ensures smooth operation and prevents costly breakdowns. For any farming or mechanical project, having a clear overview of the machine’s structure can make a significant difference in its long-term performance.

When addressing maintenance or repairs, it’s crucial to have a clear reference guide that breaks down the various components. Such a guide helps in identifying parts that need attention and provides insight into how to troubleshoot common issues. Understanding these connections is essential for both amateur and professional users.

Efficient repair and maintenance depend on recognizing the specific parts that play critical roles in overall functionality. By learning to read and use a detailed reference chart, you can approach repairs confidently, ensuring your equipment is always ready for use in the field. Whether you’re a first-time user or an experienced operator, these tools are indispensable for optimal equipment care.

Understanding Ford 3000 Tractor Components

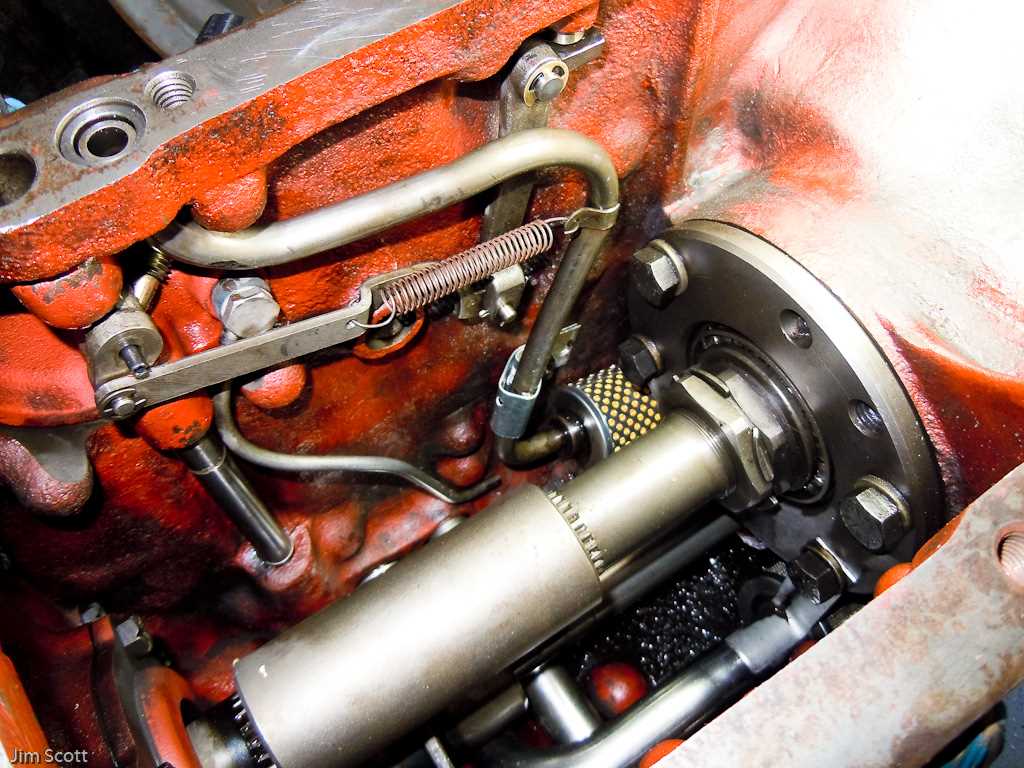

In any complex machine, every element plays a crucial role in its overall performance. A clear understanding of how these individual components work together is essential for ensuring smooth and efficient operation. From the engine to the hydraulic system, each part contributes to the overall function of the equipment, and knowing how to identify and maintain them can significantly improve longevity and productivity.

Recognizing the major components, such as the drive system, cooling mechanism, and electrical setup, allows for more effective troubleshooting and repairs. A detailed analysis of these sections helps operators understand their importance and recognize when something may be malfunctioning. Proper care of each system ensures reliability and minimizes downtime, which is particularly valuable during peak working seasons.

Efficient maintenance depends on understanding the purpose and placement of each component. With a thorough knowledge of the machine’s internal structure, operators can perform regular inspections, identify potential issues early, and make repairs before they become major problems. This proactive approach reduces repair costs and enhances overall equipment efficiency.

How to Use the Parts Diagram Effectively

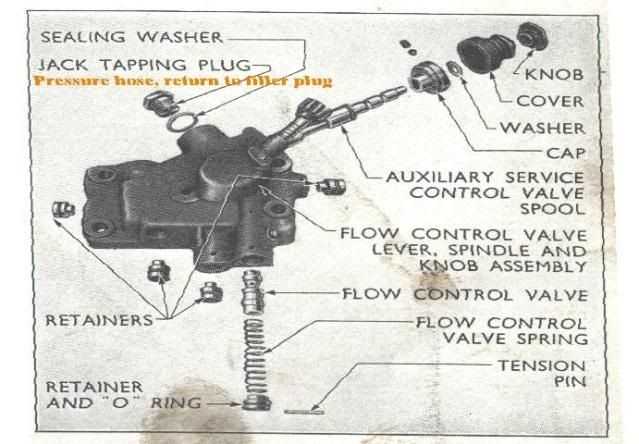

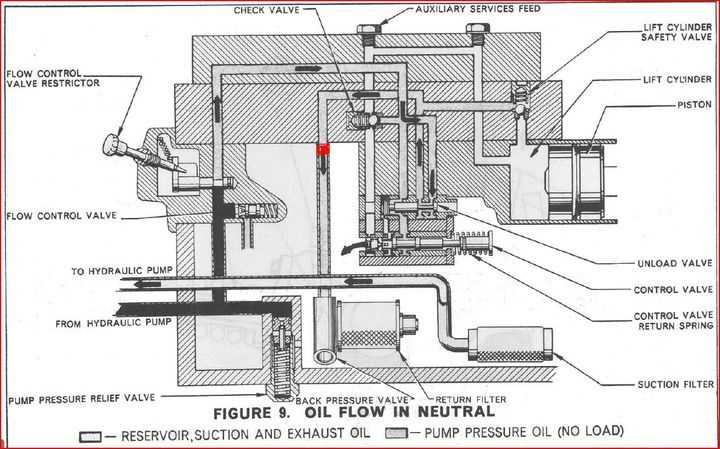

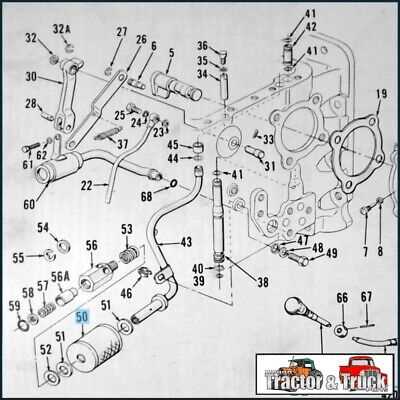

Understanding how to navigate a component reference guide is essential for maintaining and repairing machinery. Such a guide provides a visual map of the various sections, showing the correct positioning and relationship between parts. By learning to read and interpret these charts, operators can quickly identify the exact part that needs attention, streamlining the repair process and reducing unnecessary guesswork.

Start by familiarizing yourself with the layout of the guide. Most references are organized into sections based on the machine’s key systems, such as the engine, transmission, and hydraulics. Focus on the area you need to work on and find the corresponding diagram for that specific system. Pay attention to the part numbers and descriptions, as they will help you order replacements or perform maintenance more efficiently.

Effective use of the guide also involves understanding how the components fit together within the machine. This knowledge allows for quicker troubleshooting and identification of potential issues. With regular reference to the guide, you’ll develop the confidence to handle repairs independently, ensuring your equipment remains in top condition and minimizes downtime.

Common Issues and Replacement Parts for Ford 3000

Every machine experiences wear and tear over time, and understanding the most frequent issues can help minimize costly repairs. Common problems often arise from the engine, electrical system, or transmission. Identifying these issues early and replacing faulty components ensures smooth operation and prevents further damage.

One of the most common issues is with the fuel system, where clogged filters or failing injectors can lead to performance drops. Similarly, electrical problems such as faulty alternators or worn-out batteries are frequent causes of operational failures. Transmission issues, including worn-out gears or seals, can also cause the machine to lose power or operate inefficiently.

To address these problems, it’s important to have access to reliable replacement components. Ensuring you have the correct parts for each system, whether it’s a fuel filter, electrical component, or transmission seal, is crucial for maintaining optimal performance. Regular maintenance and timely replacement can extend the lifespan of your equipment and help avoid major breakdowns.