Every piece of machinery used in agriculture consists of various elements that work together to ensure smooth operation and efficiency. Knowing the specific components and how they interact can significantly improve both performance and maintenance. This section will guide you through the essential parts of a typical farming machine and how to identify each one in detail.

Proper knowledge of these elements is vital for maintaining the equipment in top condition, preventing wear, and solving common issues. A clear understanding helps operators make informed decisions about repairs, replacements, and adjustments needed for optimal functionality. Additionally, this information can assist in extending the lifespan of the machine while reducing downtime.

By familiarizing yourself with the structure and key features of agricultural machinery, you can ensure efficient planting and other related tasks. This overview will give you a deeper understanding of the important sections and their roles in the overall mechanism of the equipment, making maintenance tasks simpler and more precise.

Exploring the Essential Components of Agricultural Machinery

Understanding the individual components of farming equipment is crucial for maintaining and operating it effectively. Each machine consists of various elements that play specific roles in the overall functionality. A comprehensive breakdown of these components can help operators identify, repair, and maintain the equipment efficiently, ensuring it performs at its best throughout its lifespan.

Key Elements of Agricultural Machines

The structure of farming machinery includes a variety of interconnected parts, each designed for a particular task, such as soil preparation, seeding, or fertilization. Some of the primary elements include the transmission system, seed delivery mechanisms, and the frame that supports the entire assembly. Understanding the function of each piece is essential for diagnosing issues and ensuring smooth operation.

Common Wear and Tear in Agricultural Equipment

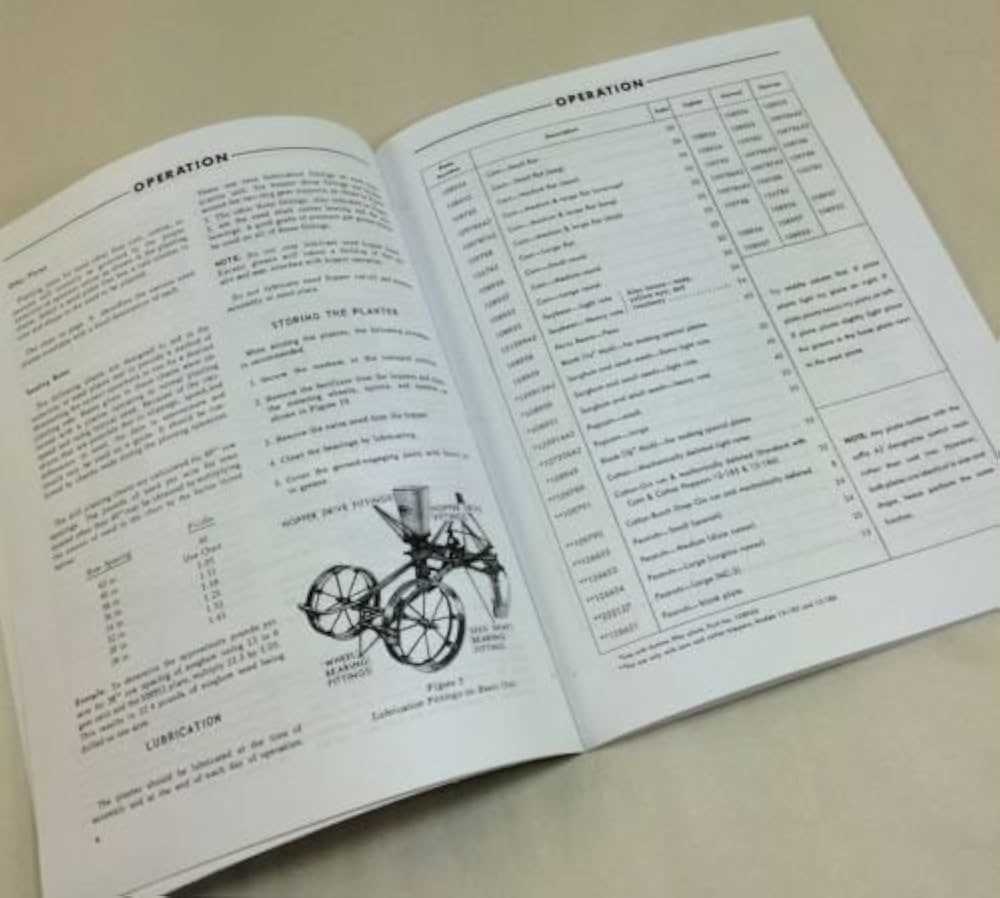

As with any machinery, certain components are more prone to wear due to the constant stresses of operation. Areas such as the seed hoppers, wheels, and mechanical drives can experience significant wear over time. Regular inspection and timely replacement of these parts are necessary to avoid major malfunctions and downtime. Proper care of these elements ensures long-lasting, efficient performance.

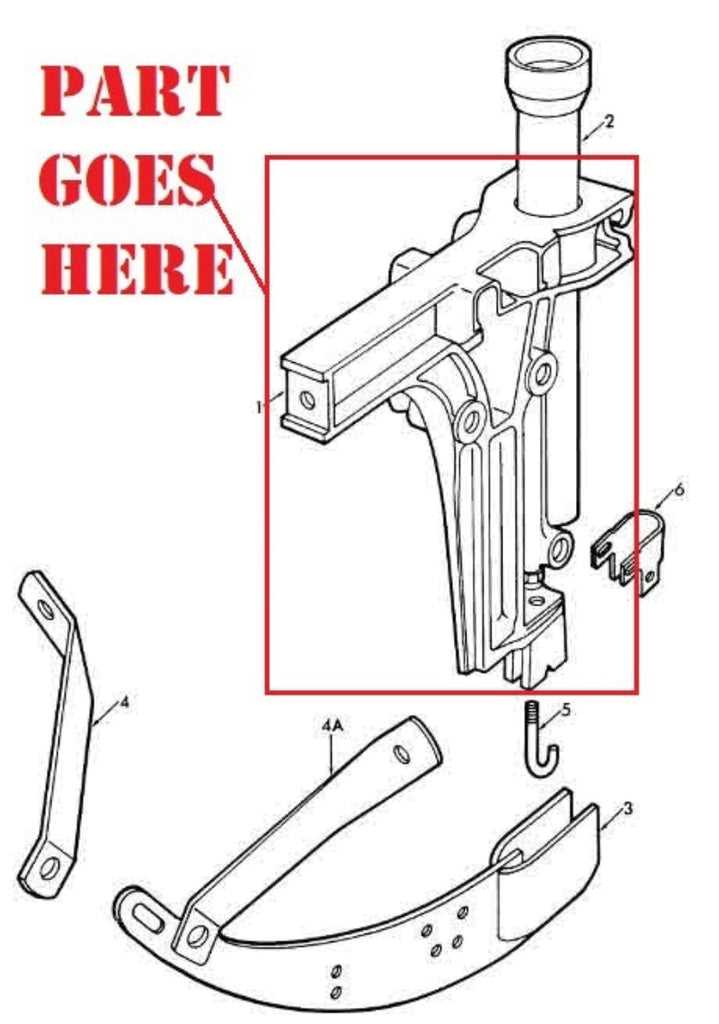

Identifying Key Components in the Diagram

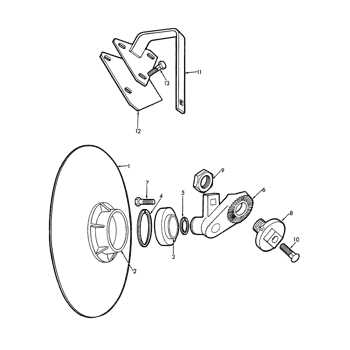

To ensure the proper functioning of any piece of agricultural equipment, it is essential to recognize the various elements that make up the machine. A clear illustration of these components allows operators to easily identify individual parts and understand their relationships. By reviewing a detailed schematic, users can pinpoint the exact locations of critical mechanisms, helping them troubleshoot issues more effectively.

Key sections typically include the transmission system, which transfers power to the working parts, and the seed delivery system, responsible for accurate planting. Additionally, the frame that supports all parts and provides stability plays a central role. Recognizing these critical components helps maintain efficiency and prolong the lifespan of the machinery.

Common Problems with Agricultural Machinery

While modern farming equipment is designed for durability, it is not immune to issues that can affect performance. Over time, components may wear down or become misaligned, causing malfunctions. Identifying and addressing these problems promptly is essential to avoid costly repairs and minimize downtime during the growing season.

Seed Delivery Issues

One of the most frequent problems in agricultural machinery is improper seed delivery. This can be caused by blockages in the seed hoppers or malfunctions in the distribution system, leading to uneven planting. Regular maintenance and cleaning of the seed delivery components are necessary to ensure smooth operation and precise seed placement.

Transmission and Drive Failures

The transmission system, responsible for transferring power to various parts, can sometimes experience failures due to wear and tear. Common issues include slipping gears or worn-out belts, which can cause reduced efficiency or complete mechanical failure. Regular inspection and timely lubrication of moving parts can help prevent such issues from occurring.

Diagnosing Issues in Planting Machinery

Properly diagnosing problems with agricultural equipment requires a systematic approach to identify the root causes of malfunctions. Whether the issue lies within the mechanical, electrical, or hydraulic systems, early detection can save time and money by preventing further damage. A thorough understanding of each machine’s components is crucial for pinpointing specific faults and taking corrective action.

Start by examining the most common issues such as inconsistent seed placement, uneven row spacing, or mechanical failures. Checking the operational components such as the drive system, seed metering devices, and soil engagement parts can help uncover potential problems. Regular checks and routine maintenance should always be part of any diagnostic process to maintain optimal performance.

Essential Maintenance for Agricultural Equipment

Regular upkeep is vital to ensure the smooth operation of farming machinery. Preventative care not only extends the lifespan of the equipment but also ensures it functions at peak performance, minimizing downtime during critical planting periods. Proper maintenance includes both routine checks and more detailed inspections to detect potential issues before they become serious problems.

Key Maintenance Tasks

- Inspect seed delivery mechanisms for wear and blockages.

- Lubricate moving parts such as gears and wheels to reduce friction.

- Check the condition of belts and adjust tension as needed.

- Clean and calibrate the seed meter system to ensure accurate planting.

When to Perform Maintenance

- Before the start of each planting season to ensure readiness.

- After any heavy use to check for signs of wear and tear.

- Following any unexpected malfunction or breakdown to prevent further damage.