Maintaining heavy machinery is crucial for ensuring its longevity and optimal performance. Understanding the intricate network of its various components plays a key role in troubleshooting and repair. A clear visual breakdown helps identify issues and supports efficient fixes, ultimately reducing downtime during farming operations.

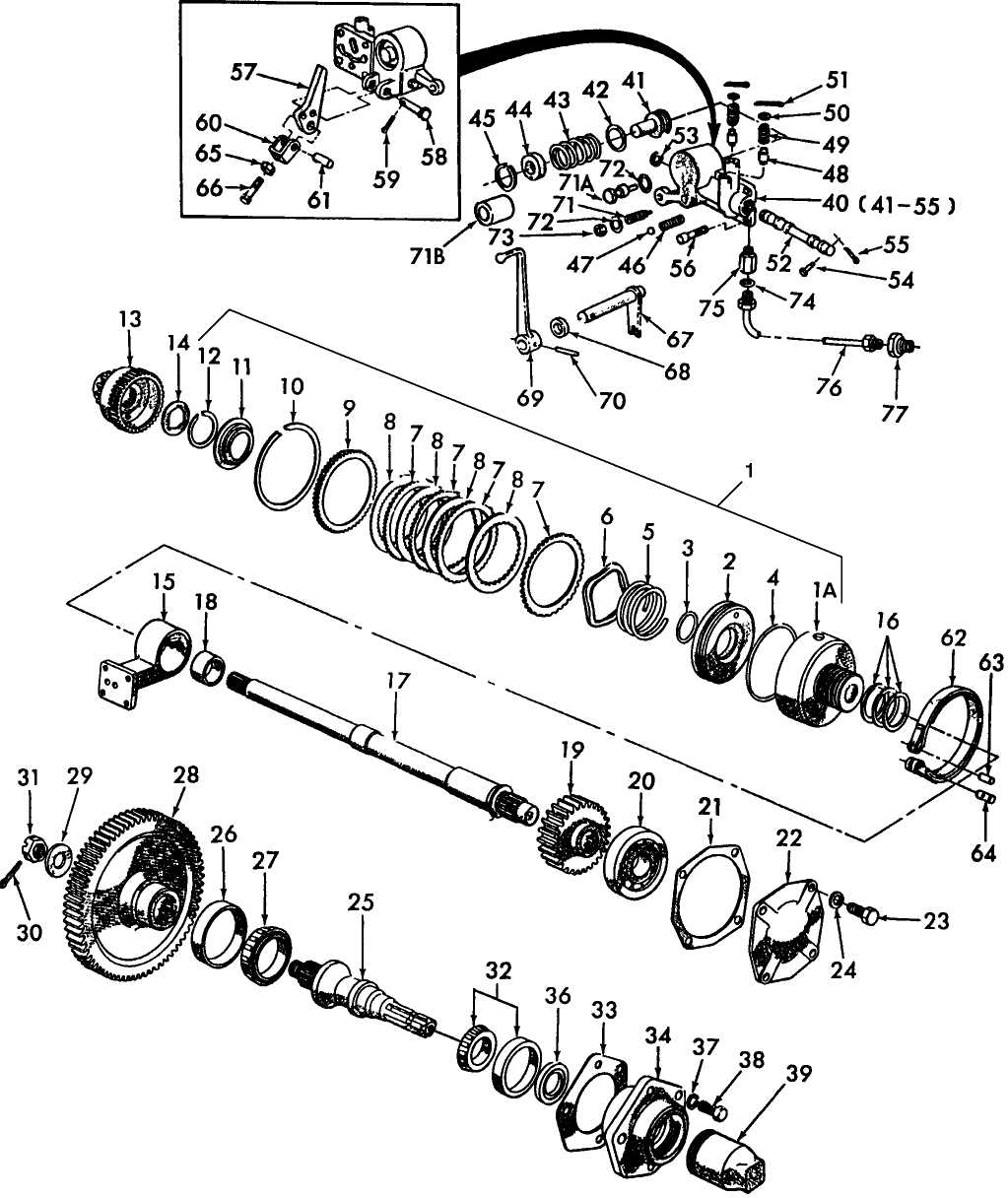

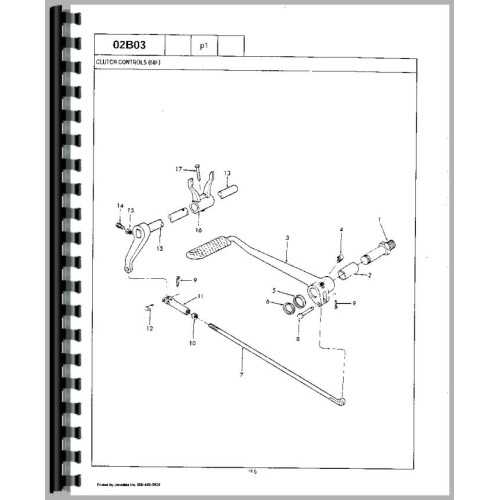

Accurate identification of each piece and its function is essential for anyone looking to maintain or restore a machine. Knowing where parts are located and how they interact is the first step in avoiding costly repairs and extending the lifespan of the equipment. By studying the layout and understanding the connection between each element, operators can effectively keep the machine in working order.

Whether you’re a seasoned mechanic or a first-time owner, having access to a well-organized schematic can make all the difference when facing mechanical challenges. The ability to quickly locate and replace defective components will ensure that the machinery operates at its best for years to come.

Understanding the Agricultural Machine Components

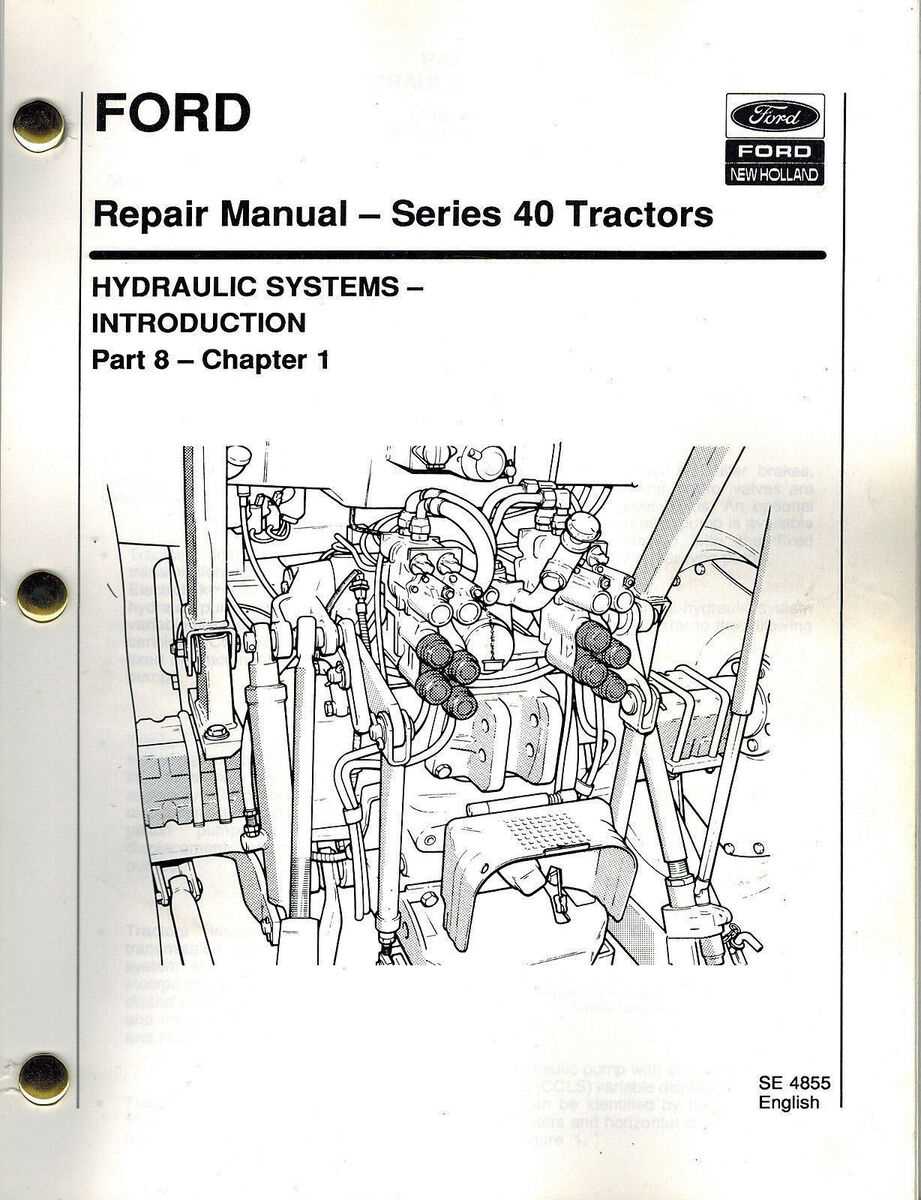

Every machine designed for farming relies on a series of interconnected systems that work together to provide power and functionality. These systems include the engine, hydraulic components, transmission, and various control mechanisms, each serving a specific role. Understanding how these elements function and interact ensures efficient operation and simplifies maintenance tasks.

The engine is the heart of the machine, providing the necessary power to drive all other systems. The hydraulic system, on the other hand, plays a vital role in facilitating lifting and moving heavy loads. The transmission ensures that the right amount of power is transferred to the wheels, allowing the operator to control speed and direction. Together, these systems form a cohesive unit, with each part contributing to the overall effectiveness of the machine.

Familiarity with these components is essential for troubleshooting and repair. A well-maintained understanding of their locations and functions enables operators to quickly diagnose issues, replace faulty elements, and keep the machine running smoothly. A clear grasp of the entire setup ultimately minimizes downtime and ensures the equipment remains reliable in the field.

Common Issues and Parts Replacement Tips

In any piece of agricultural equipment, frequent wear and tear can lead to a range of operational issues. These problems often arise from the constant strain placed on key systems like the engine, transmission, and hydraulic components. Recognizing the most common issues early can prevent costly repairs and downtime in the field.

One of the most common problems faced by operators is engine overheating. This can occur due to a malfunctioning radiator, worn-out cooling hoses, or insufficient coolant levels. Regularly checking these components and replacing them as needed is vital to maintaining engine performance. Another frequent issue is worn belts or damaged pulleys, which can cause the machine to lose power or efficiency. Replacing these items promptly can help avoid more serious mechanical failures.

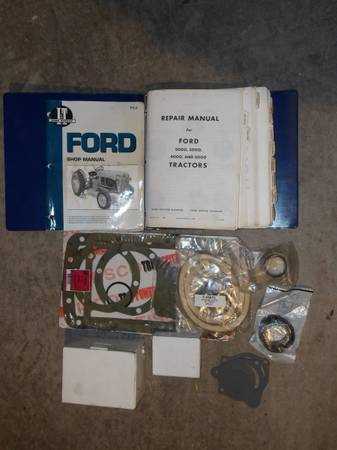

When it comes to replacing components, always opt for high-quality replacements that meet the specifications of your machine. Proper installation and regular maintenance are key to ensuring the longevity of the equipment. Keeping an eye on fluid levels, checking for leaks, and replacing filters at recommended intervals will also help to extend the lifespan of the machinery.

Step-by-Step Repair Process

When tackling repairs on agricultural machinery, a methodical approach is crucial to ensure efficiency and accuracy. By breaking down the repair process into clear, manageable steps, you can address each issue systematically, ensuring nothing is overlooked. This approach not only helps resolve current problems but also prevents future complications.

Start by performing a thorough inspection of the equipment to identify any visible damage or malfunctioning components. This includes checking the engine, hydraulic system, and transmission for signs of wear or leaks. Once the problem areas are identified, gather the necessary tools and replacement components. Carefully follow manufacturer instructions for disassembly, paying attention to the order in which parts are removed to avoid confusion during reassembly.

After replacing or repairing the faulty parts, reassemble the machinery, ensuring all connections are secure and properly aligned. Once the machine is back together, conduct a series of tests to verify that the issue has been resolved. Finally, perform routine maintenance tasks such as fluid checks and filter replacements to keep the equipment in peak condition. Regular follow-up inspections and preventative care will help extend the lifespan of the machine.