Understanding the inner workings of construction machinery is essential for maintaining performance and efficiency. Every heavy-duty machine consists of numerous parts that must work in harmony to achieve optimal results. Knowing how these components are arranged and how they function together is crucial for anyone looking to perform repairs or upgrades on their equipment.

By exploring a detailed illustration of the various sections and elements within an excavator, operators and technicians can identify potential issues early and make informed decisions about necessary replacements. This knowledge not only saves time but also ensures that machinery runs smoothly, minimizing downtime during crucial projects.

In this article, we will dive into the breakdown of an excavator’s essential components, providing a guide that simplifies maintenance and repair tasks. Understanding the layout of the machine can significantly reduce costly mistakes and improve overall operational efficiency.

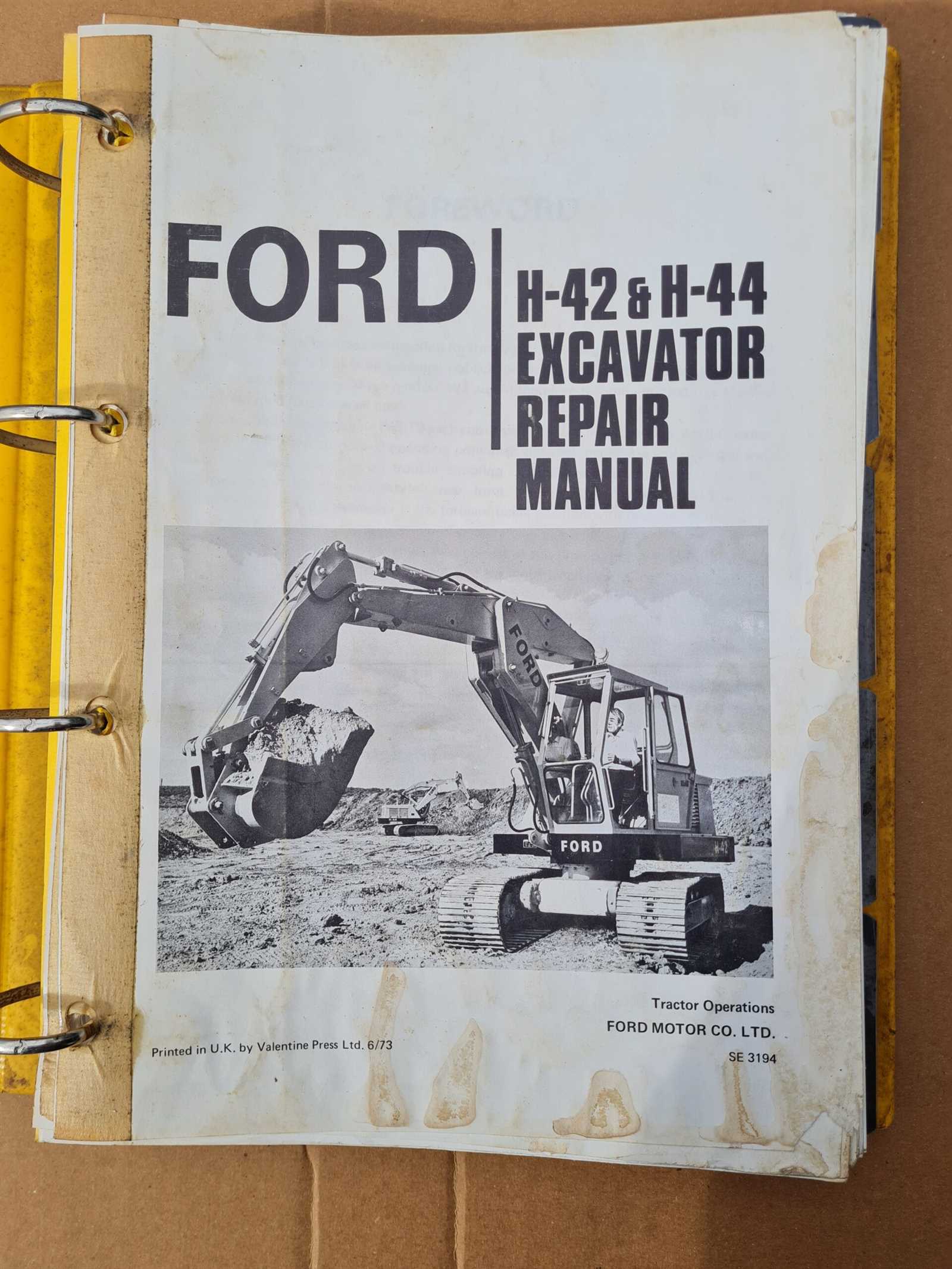

Understanding the Excavator Components

Heavy machinery used in construction is composed of multiple interrelated systems and elements. Each component plays a crucial role in ensuring the machine operates efficiently and effectively. Understanding the structure and arrangement of these components allows for easier maintenance, quicker identification of potential issues, and a more streamlined repair process. Knowing how everything fits together is key to getting the best performance from your equipment.

Main Systems and Functions

The primary systems in an excavator include the hydraulic system, engine, and the various mechanical linkages that allow movement. Each system is designed to perform specific functions, from lifting and digging to steering and stabilizing. By studying the layout of these systems, operators can better understand the purpose of each component and how they work together to perform complex tasks.

Commonly Replaced Components

Over time, certain components are more likely to wear out due to constant use. Items such as hydraulic cylinders, joints, and seals often require replacement. Recognizing these parts early on can prevent more serious issues from developing and keep the machine running smoothly for longer periods. Familiarity with the common parts that need attention helps maintain the efficiency and longevity of the machine.

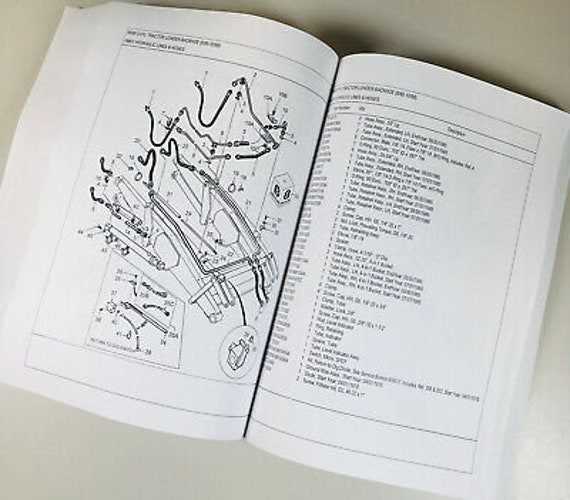

How to Use the Parts Diagram Effectively

Understanding the layout of a machine’s components is vital for efficient repair and maintenance. A visual representation of the parts helps to quickly identify and locate specific elements, saving time and reducing the likelihood of errors. To make the most of this resource, it’s important to approach it systematically, paying attention to details that will guide you through the entire maintenance process.

Step-by-Step Guide

To maximize the usefulness of the visual breakdown, follow these steps:

- Identify the system: Start by locating the system you are working on, such as the hydraulic or mechanical components.

- Locate the part: Once the system is identified, find the exact part you need to inspect or replace.

- Check the reference numbers: Use the reference numbers provided to cross-check with the service manual or ordering information.

- Understand the connections: Pay attention to how the parts are connected, which will help during disassembly or reassembly.

Tips for Efficiency

To further enhance your ability to work with the diagram, keep these tips in mind:

- Use a digital or printed version of the illustration for easy zooming and clarity.

- Label parts clearly to avoid confusion during repairs.

- Regularly refer to the diagram during maintenance to ensure all parts are correctly assembled and functioning.

Common Issues and Replacement Parts for Excavators

Machines used in construction are subject to wear and tear due to their constant operation in tough environments. Over time, certain components may become damaged or show signs of deterioration, affecting the overall performance of the equipment. Identifying common issues early on and knowing which parts to replace can prevent more costly repairs and minimize downtime.

Common Problems in Heavy Machinery

Several components often face challenges during the life of an excavator, including:

- Hydraulic system leaks: Over time, hoses and seals can degrade, leading to fluid leakage, which affects the machine’s lifting and digging capabilities.

- Worn-out joints and bearings: These parts undergo a lot of stress and are frequently in need of replacement to maintain smooth operation.

- Engine performance issues: Reduced engine power or irregular function can result from worn-out fuel filters, spark plugs, or air filters.

Replacement Components to Watch For

Regularly replacing worn-out parts is key to maintaining the functionality of your machine. Some common replacement parts include:

- Hydraulic seals and cylinders

- Engine filters and fuel injectors

- Drive belts and tensioners

- Shock absorbers and suspension components