Understanding the structure of any heavy-duty machine is crucial for its long-term performance. A detailed overview of its key elements helps users recognize their purpose and ensure proper maintenance. Knowing how everything fits together allows for more efficient handling and repair.

Identifying each component within such equipment is vital for both routine upkeep and troubleshooting. This knowledge enables users to address issues promptly, preventing larger malfunctions. Additionally, learning how to maintain these crucial parts extends the operational lifespan and improves overall functionality.

Proper care and attention can significantly reduce repair costs and downtime. With the right knowledge, operators can work confidently, making informed decisions to keep the machinery running smoothly in various conditions.

Understanding Key Components

To effectively operate and maintain a heavy-duty machine, it is essential to have a clear understanding of its fundamental elements. Each individual component plays a vital role in the overall functioning of the equipment. Recognizing their specific functions ensures that the machine runs smoothly and efficiently over time.

Core Functions of Essential Elements

The primary elements of any machinery work together in harmony to support various tasks. From the engine to the control systems, each component contributes to the machine’s performance. A well-maintained structure can greatly improve its output and longevity, while neglecting any part may lead to malfunctions.

Importance of Regular Inspection

Periodic checks on key components are crucial for identifying potential issues before they become significant problems. By routinely assessing each essential part, operators can catch early signs of wear and tear, minimizing the risk of failure during operation. Proper inspection ensures the continued effectiveness of the machine.

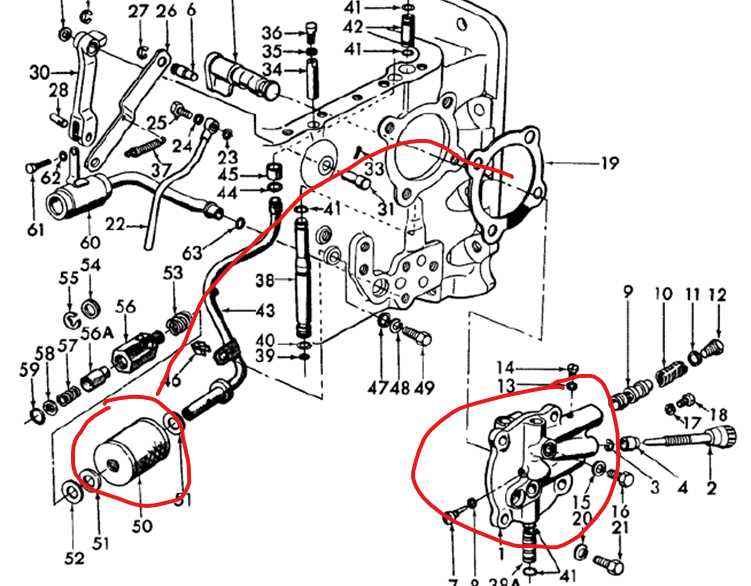

Key Parts and Their Functions

Every machine consists of critical components that serve specific functions to ensure efficient operation. Understanding these elements and how they contribute to the overall performance is essential for effective maintenance and troubleshooting. Recognizing the role of each part can help operators maximize the equipment’s potential and extend its lifespan.

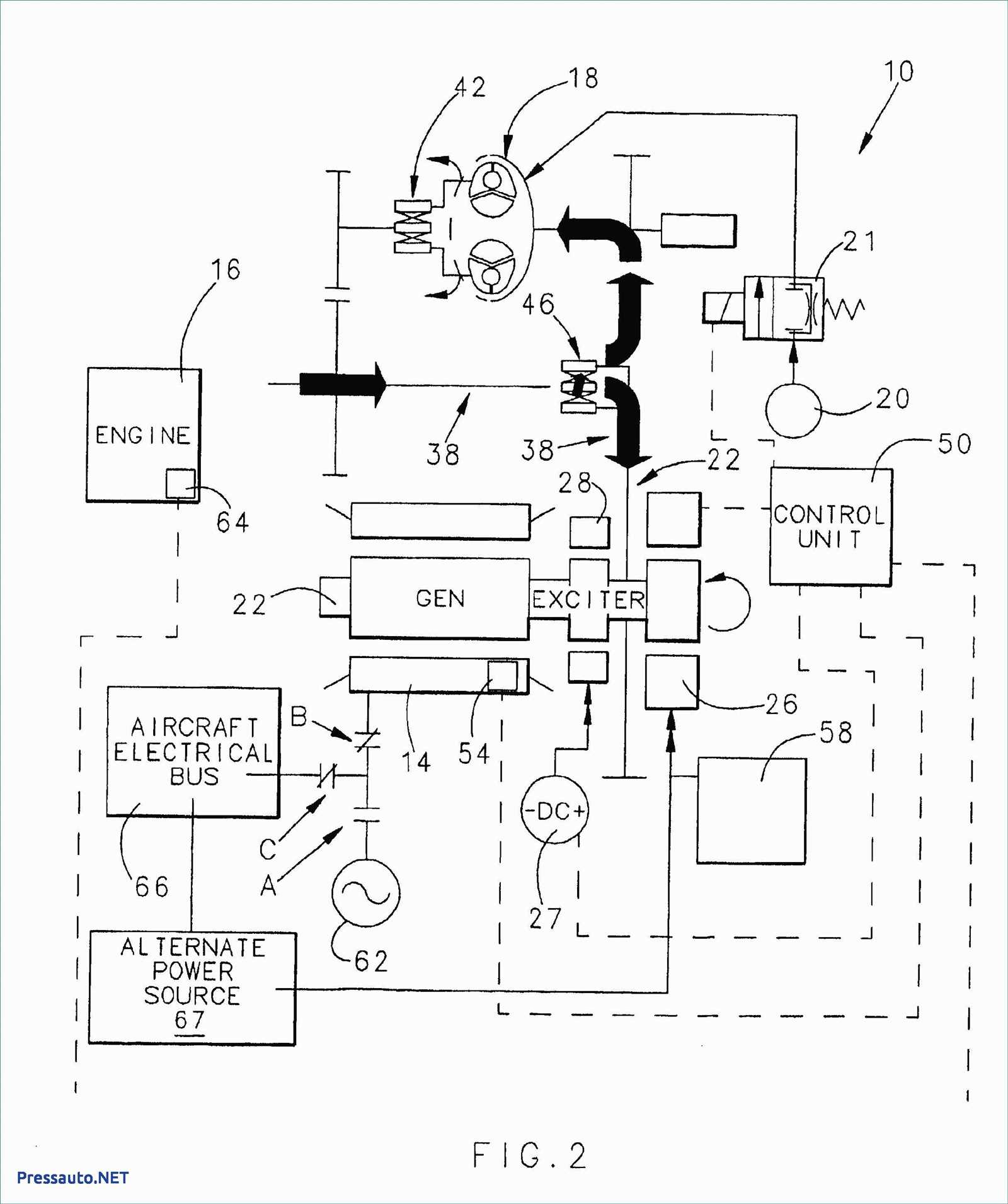

Engine and Power Transmission

The engine is the heart of any machine, providing the necessary power for movement and other essential tasks. The power transmission system works to transfer this power to the wheels or other mechanisms, allowing the equipment to perform various functions. Together, these components form the driving force that enables the machinery to complete its tasks efficiently.

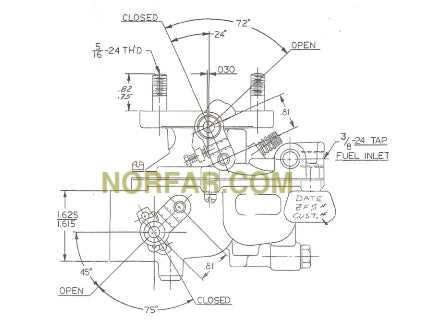

Control Mechanisms and Hydraulics

Control systems and hydraulic components are responsible for managing the operations of different elements, ensuring precision and adaptability. These systems allow the operator to control movements, adjustments, and various functions with ease. Proper maintenance of these components is vital for optimal performance, as they provide the responsiveness and flexibility needed for different tasks.

Maintenance Tips for Heavy-Duty Equipment

Proper upkeep is crucial for ensuring the longevity and efficiency of any heavy machinery. Regular maintenance not only improves performance but also prevents costly repairs. By following a consistent maintenance schedule, operators can keep their equipment running smoothly and avoid unexpected downtime.

Routine Inspections

Conducting frequent inspections is essential for identifying any wear and tear early on. Check the vital components such as the engine, transmission, and hydraulic systems for any signs of damage or deterioration. Timely intervention can help avoid more significant issues down the line, ensuring that the machine performs at its best.

Fluid Levels and Lubrication

Maintaining proper fluid levels and ensuring that all moving parts are adequately lubricated is critical for the smooth operation of the equipment. Regularly check oil, hydraulic fluids, and coolant to prevent overheating and friction that could lead to component failure. Adequate lubrication minimizes wear, enhancing the overall lifespan of the machine.