When working on any heavy-duty vehicle, understanding the layout of its internal components is essential for efficient maintenance and repair. With the right knowledge, mechanics and enthusiasts can easily identify each part and its specific function within the system. This insight allows for smoother diagnostic processes and quicker resolutions to common issues.

Knowing the correct structure of these systems not only helps with identifying wear and tear but also ensures proper replacements when necessary. It’s crucial to become familiar with how parts are organized and how they interact with each other, as this will provide a clearer picture of the vehicle’s overall performance.

By mastering the visual representation of these systems, owners can confidently navigate through maintenance tasks and repairs, reducing downtime and increasing the lifespan of the vehicle. Whether it’s replacing a worn-out component or upgrading to a more advanced version, understanding the layout is the first step toward successful service.

Understanding the Vehicle Component Layout

Knowing the arrangement of key elements within a vehicle is crucial for anyone looking to perform maintenance or repair tasks. Each part has a specific role in the overall function of the system, and understanding how they connect and work together can significantly improve both efficiency and accuracy when diagnosing issues.

The layout of these components is typically organized in a clear and logical manner, with each section of the vehicle housing certain parts that contribute to its performance. From the engine to the suspension, every group of components interacts with others to ensure smooth operation, and being familiar with this setup allows for more precise interventions.

Familiarity with the system layout helps in identifying wear points, preventing issues before they become major problems, and making well-informed decisions when replacement or repairs are required. This knowledge is invaluable not only for professional technicians but also for vehicle owners who wish to better understand their machine’s inner workings.

How to Read a Vehicle Component Layout

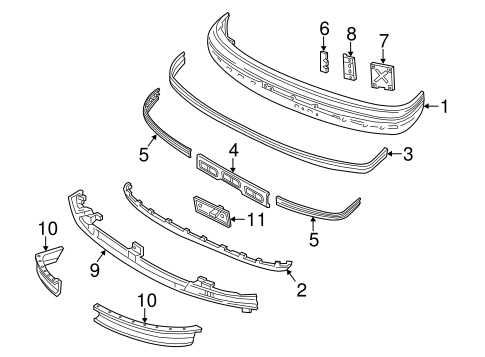

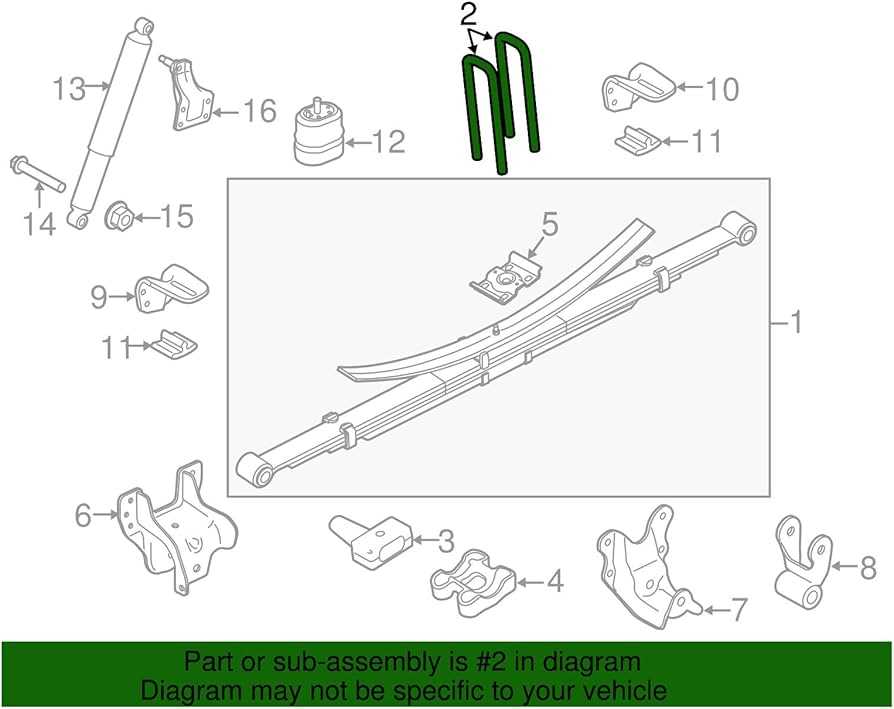

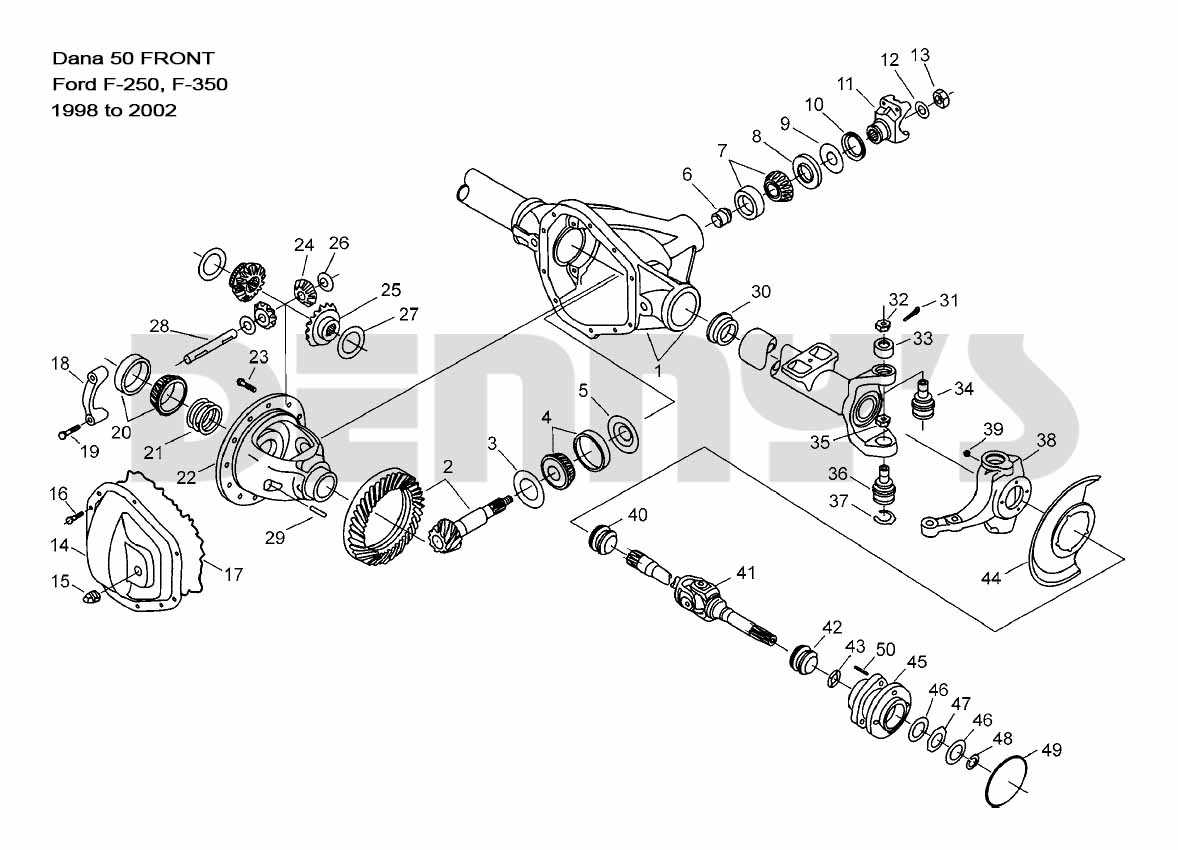

Understanding how to interpret a visual guide of a vehicle’s inner workings is essential for effective maintenance and repair. A component layout typically includes detailed representations of the various parts within the system, each labeled for easy identification. Knowing how to read these layouts helps ensure accurate repairs and efficient troubleshooting.

Identifying Key Elements

The first step in reading any layout is identifying the main sections of the vehicle. These sections are typically grouped by their function–engine components, suspension elements, electrical systems, and so on. Each part will be clearly marked, often with numbers or codes that correspond to a parts list or catalog, which makes finding replacements or performing checks much easier.

Understanding Connections and Relationships

In addition to recognizing individual parts, it’s important to understand how they interact with one another. Many diagrams highlight connections or points of contact between components, helping you visualize the flow of energy, fluids, or other critical functions. Recognizing these relationships enables better planning for repairs or upgrades, ensuring that each part’s role is fully understood.

Common Issues and Solutions for Vehicle Components

Every vehicle, regardless of make or model, experiences some common issues related to its internal systems. From wear and tear to environmental factors, the components within the vehicle are subject to stress over time. Recognizing these problems early and knowing the appropriate solutions can save time and money in the long run.

Engine performance issues are often linked to clogged filters or faulty sensors. These problems can result in poor fuel efficiency or reduced power. Regularly checking these elements and replacing them when necessary can prevent costly repairs. If engine light indicators appear, diagnosing the issue using the component layout can pinpoint the exact cause.

Suspension and brake system failures are also common, especially with vehicles subjected to heavy use. Worn-out shock absorbers or brake pads can lead to reduced handling and longer stopping distances. Regular inspection and timely replacements ensure that the vehicle maintains its performance and safety on the road.