Proper maintenance and repair of heating systems require an understanding of the various elements that make up these essential appliances. Knowing the function and structure of each component can help troubleshoot issues effectively and ensure the system works smoothly throughout its lifespan.

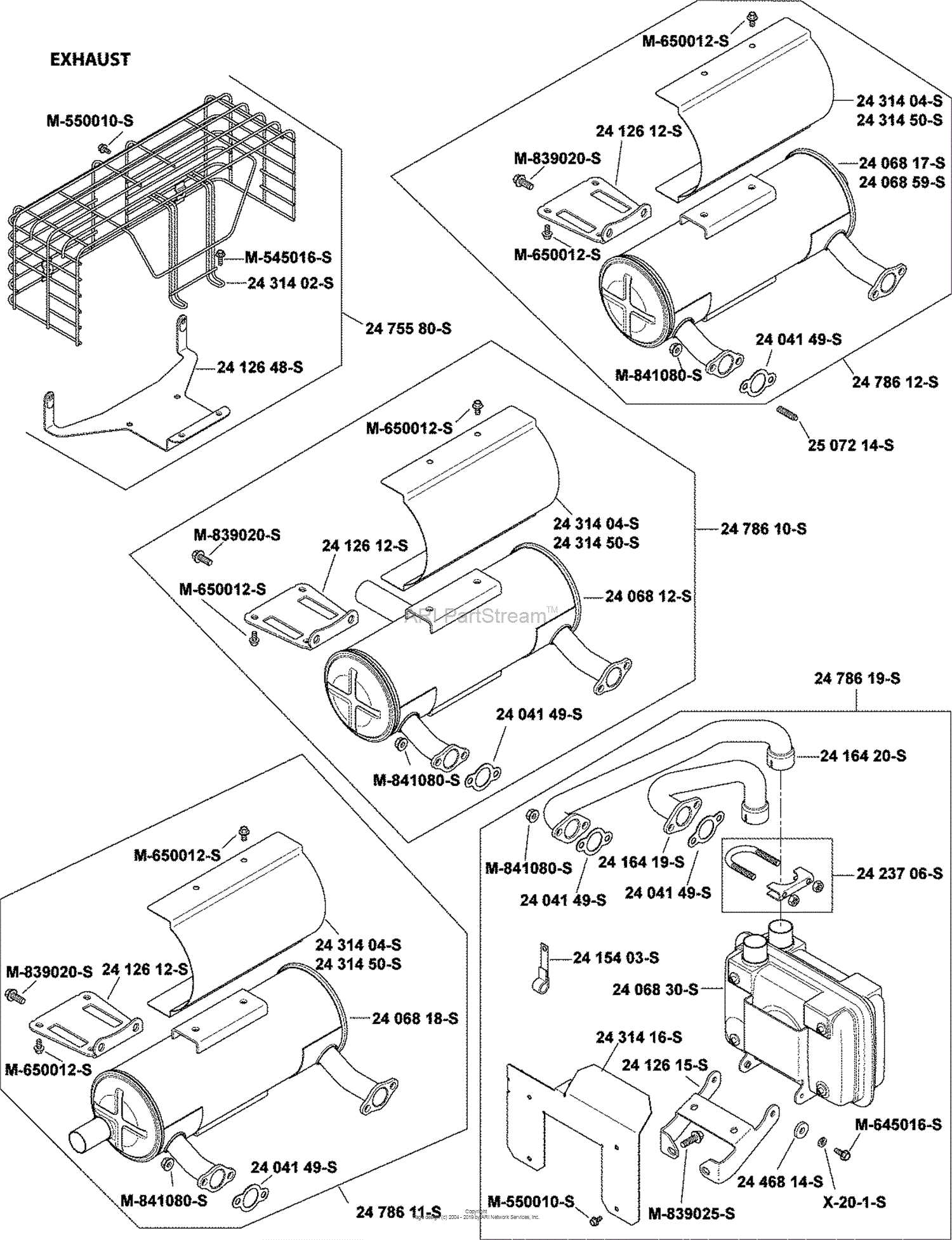

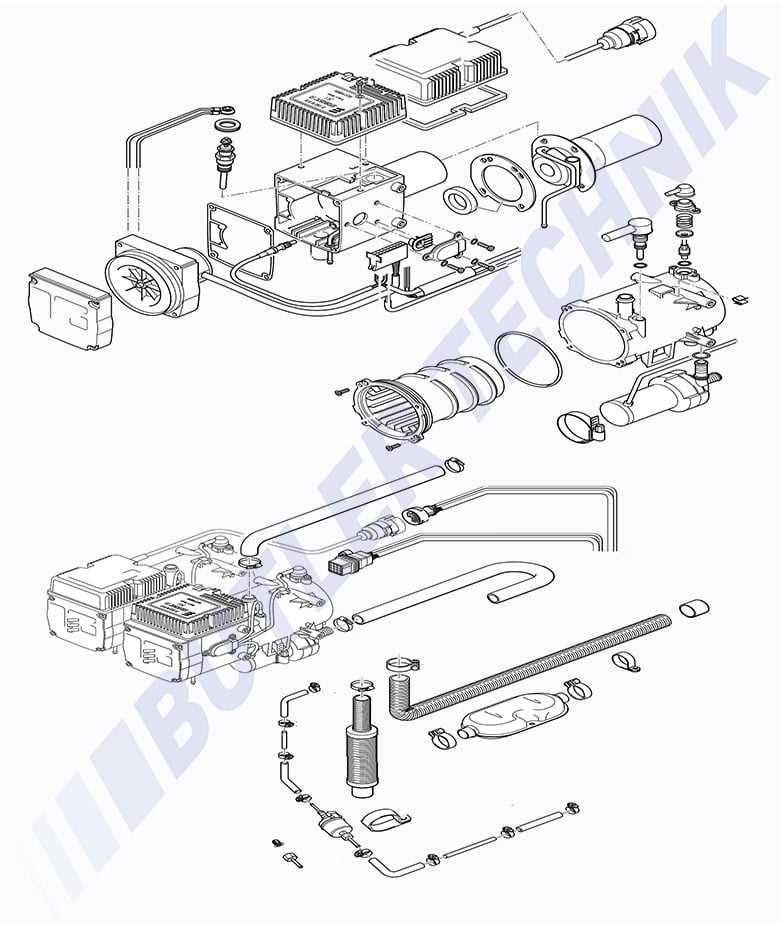

Visual guides that illustrate the internal components can be extremely helpful for both professionals and homeowners. These resources provide clear references, allowing users to pinpoint the specific part they need to inspect or replace. Understanding how each piece interacts within the system can save time and effort during repairs.

By familiarizing yourself with the key elements involved, you can approach any problem with confidence, knowing exactly where to look and what to look for. A well-informed approach can lead to more efficient repairs and better performance from your equipment.

Understanding Heating System Components

Efficient operation of any heating appliance relies on the proper functioning of its individual components. Each element within the system serves a specific role, and understanding these functions can help you identify potential problems and address them with confidence. Knowing how these parts work together ensures smoother performance and longer-lasting operation.

Key Elements in a Heating Unit

The core components of a heating system include the heating element, temperature control unit, and safety mechanisms. Each of these parts is essential for the device’s overall operation. For example, the heating element generates the heat, while the control unit regulates the temperature to maintain a comfortable environment. Additionally, safety features like sensors and switches prevent overheating or malfunctions, ensuring safe operation.

Maintaining Component Efficiency

Regular inspection and maintenance of these components are crucial to keep the system running efficiently. Identifying wear and tear or damage to parts such as the thermostat, fan motor, or electrical connections can prevent larger issues from developing. Routine checks help to keep the system operating at its best, reducing the need for costly repairs and improving energy efficiency.

Common Issues and Solutions for Heating Systems

Over time, heating systems can develop issues that impact their performance. Understanding these common problems and knowing how to address them can save time, effort, and money. Many of these issues are straightforward to fix, provided the proper steps are followed and the right parts are identified.

Temperature Irregularities

One of the most frequent problems is inconsistent temperature control. This issue may arise from a malfunctioning thermostat or a dirty sensor. Cleaning the sensor or recalibrating the thermostat can often resolve this problem. If these steps don’t help, replacing the faulty components may be necessary.

Reduced Heating Efficiency

When the system struggles to heat a space effectively, it often indicates that air flow is obstructed or the system is clogged. This could be caused by dust accumulation in the filters or a malfunctioning fan motor. Cleaning or replacing the filters and ensuring that the fan is working properly should improve efficiency. If airflow continues to be restricted, the ductwork might need to be inspected for blockages.

How to Use the Heating System Layout Effectively

Having a visual representation of the internal components of a heating system can be incredibly valuable when troubleshooting or performing maintenance. This type of guide provides a clear overview of the device’s structure, allowing you to locate specific elements and understand their functions in relation to one another. By following a well-organized layout, identifying problems becomes a much simpler task.

Step-by-Step Inspection Process

To make the most of a component map, begin by identifying the major sections of the system, such as the control unit, heating element, and safety mechanisms. Carefully follow the flow of energy and heat, noting where potential failures might occur. This methodical approach allows for quicker identification of malfunctioning parts without needing to dismantle the entire unit.

Troubleshooting with Precision

A detailed schematic helps you focus on the specific area of the system where issues are most likely to arise. By referencing the diagram, you can avoid unnecessary disassembly and make targeted repairs. Whether dealing with electrical faults, temperature irregularities, or airflow problems, using the layout as a guide will streamline the troubleshooting process, making repairs more efficient and precise.