Maintaining an efficient heating system requires understanding the key elements that ensure smooth operation. By familiarizing yourself with the individual components, troubleshooting becomes more manageable, helping you keep the equipment in top condition. Whether you’re performing a routine check or dealing with specific malfunctions, knowing the internal structure is essential for proper care.

Understanding the inner workings of your system can prevent unexpected breakdowns and prolong its lifespan. With a clear overview of each part’s function and placement, it’s easier to identify potential issues and take necessary steps before they escalate.

Knowing the layout of the components also makes repair or replacement more efficient. With the right visual aid, any confusion about where each part is located disappears, simplifying maintenance tasks. This knowledge empowers you to make informed decisions, whether you’re hiring a professional or tackling the job yourself.

Understanding Heating System Components

To keep a heating system functioning properly, it’s essential to understand the various elements that work together to create optimal performance. Each component has a specific role, and when one part malfunctions, it can affect the entire system. By becoming familiar with the structure and function of each part, you can more effectively diagnose issues and ensure efficient operation.

Key Elements and Their Functions

Every unit contains several crucial components, such as the control board, heating element, and safety sensors. The control board regulates the overall system, sending signals to various parts to manage temperatures and functions. The heating element directly converts energy into heat, while sensors monitor the internal environment, ensuring the system operates within safe parameters.

Maintenance and Troubleshooting Tips

Proper maintenance is vital for preventing wear and tear on essential components. Regularly checking the wiring, cleaning filters, and ensuring sensors are calibrated will help maintain efficiency. When problems arise, understanding the location and function of each element will enable you to troubleshoot with ease, identifying whether an issue is related to the control system, the heating mechanism, or other critical parts.

Common Issues with Heating System Components

Like any complex system, heating units can experience a variety of malfunctions over time. Common issues often arise from wear and tear, improper maintenance, or faulty components. Understanding these potential problems is crucial for effective troubleshooting and ensuring the system runs smoothly.

One frequent issue is a malfunctioning control system, which can lead to incorrect temperature regulation or complete failure of the unit. Faulty wiring or electrical connections may cause intermittent operation or prevent the system from turning on altogether. Another issue can occur with the sensor that monitors temperature and safety levels. If the sensor is miscalibrated or damaged, the system may overheat or shut down prematurely.

Clogged filters or dirty coils can also hinder performance, leading to poor heat output and reduced efficiency. If these components are not regularly cleaned or replaced, they can strain the entire system, causing premature failure. Identifying and addressing these common issues promptly can prevent more serious damage and extend the lifespan of the equipment.

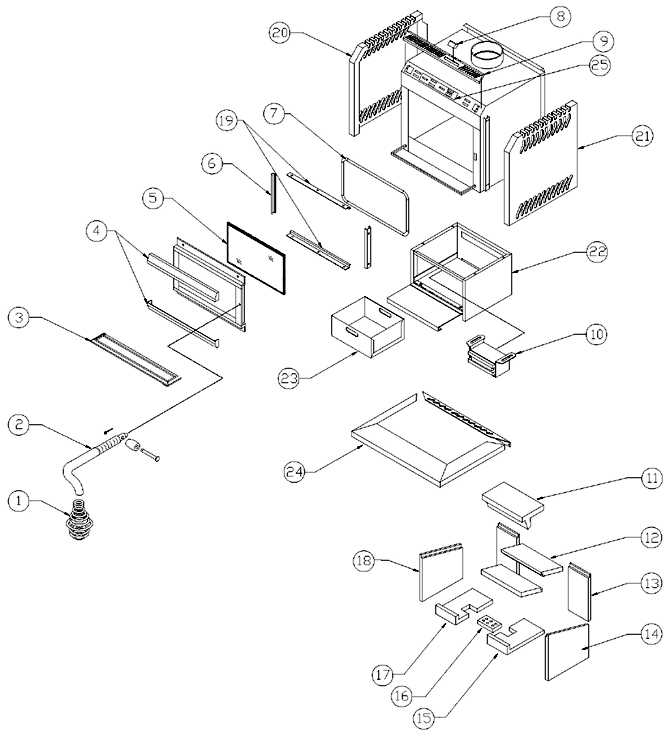

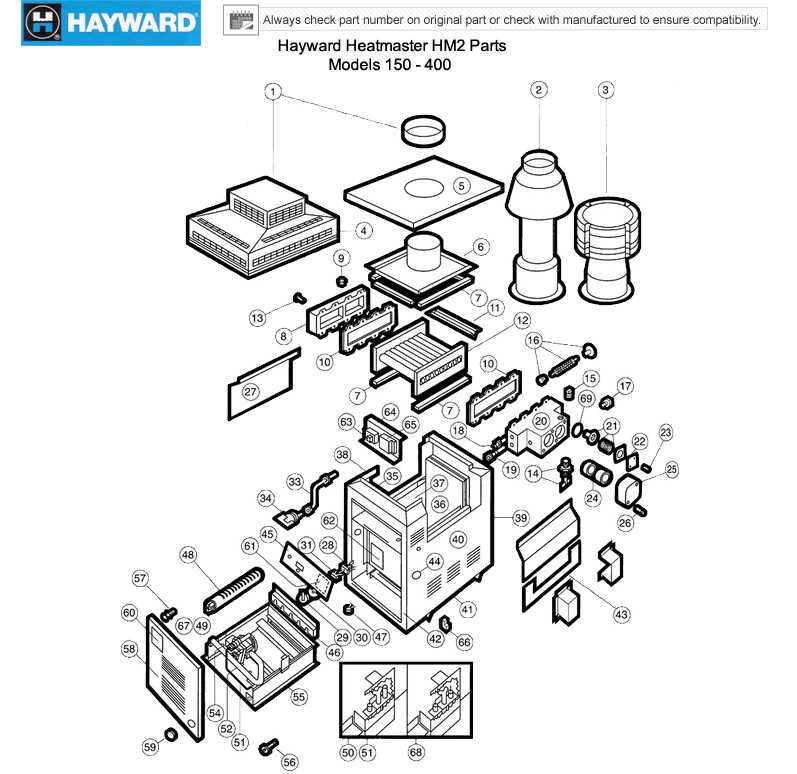

How to Read Heating System Component Layout

Understanding the layout of a heating system’s internal components is crucial for effective maintenance and troubleshooting. A detailed schematic provides a visual guide that shows how each part interacts with the others, allowing for easier identification of issues. Knowing how to read this layout can save time and help you quickly address problems without unnecessary confusion.

Breaking Down the Visual Guide

The component layout is usually broken down into sections that represent different areas of the system. Each section corresponds to a specific function, such as the control system, energy source, or temperature regulation. When looking at the diagram, pay attention to the following key elements:

- Labels: Each component is clearly marked, often with both a name and a unique identifier, making it easier to locate specific parts.

- Connections: Lines or arrows indicate how components are linked, helping you understand the flow of energy and signals between them.

- Symbols: Icons or simplified graphics represent different types of parts, such as electrical components, sensors, or mechanical elements.

Interpreting the Layout for Troubleshooting

Once you understand the basic layout, use the schematic to track potential malfunctions. If a component fails, the diagram can guide you in locating the part that needs attention. For example, if a temperature sensor is malfunctioning, the diagram will show its precise location, enabling you to test it directly or replace it if necessary.

Overall, a well-organized schematic not only simplifies the repair process but also helps you understand how each part contributes to the system’s overall function.