Maintaining a heating system can be a complex task, especially when it comes to identifying the components that require attention. Knowing the layout and function of each part is crucial for effective repairs and longevity. Understanding how different pieces interact within the unit is the first step in ensuring proper functionality and avoiding unnecessary breakdowns.

By exploring the various components that make up these systems, you can quickly spot issues before they become significant problems. This knowledge helps in troubleshooting, ordering replacement parts, and making sure that everything is working at optimal performance. Proper identification of the necessary elements can save both time and money in the long run.

Familiarity with the structure of the system also allows users to take preventive measures, enhancing the efficiency and safety of operation. In this guide, we break down the essential components and offer tips for effective maintenance and repair. With the right understanding, you can ensure a smooth and uninterrupted heating experience.

Understanding the Key Components

Every efficient system relies on a series of interconnected components working together seamlessly. Identifying and understanding each element is crucial for proper functioning and troubleshooting. Without knowing what each part does, it becomes challenging to diagnose issues or perform effective repairs. This section explores the main elements involved in the system, offering insight into their roles and how they contribute to overall performance.

Main Elements of the System

The core elements include those that regulate temperature, manage airflow, and provide the necessary power for operation. Each part has a unique function, from controlling the internal temperature to ensuring smooth operation across various settings. Recognizing how these components interact helps in maintaining the system’s efficiency and identifying potential issues early on.

How Components Work Together

The interaction between components is key to the seamless performance of the entire unit. A disruption in one area can lead to malfunctioning across the system. By understanding the flow of energy, heat, and air through the different parts, it becomes easier to pinpoint where problems may arise. Regular maintenance and awareness of the system’s structure ensure longevity and optimal performance.

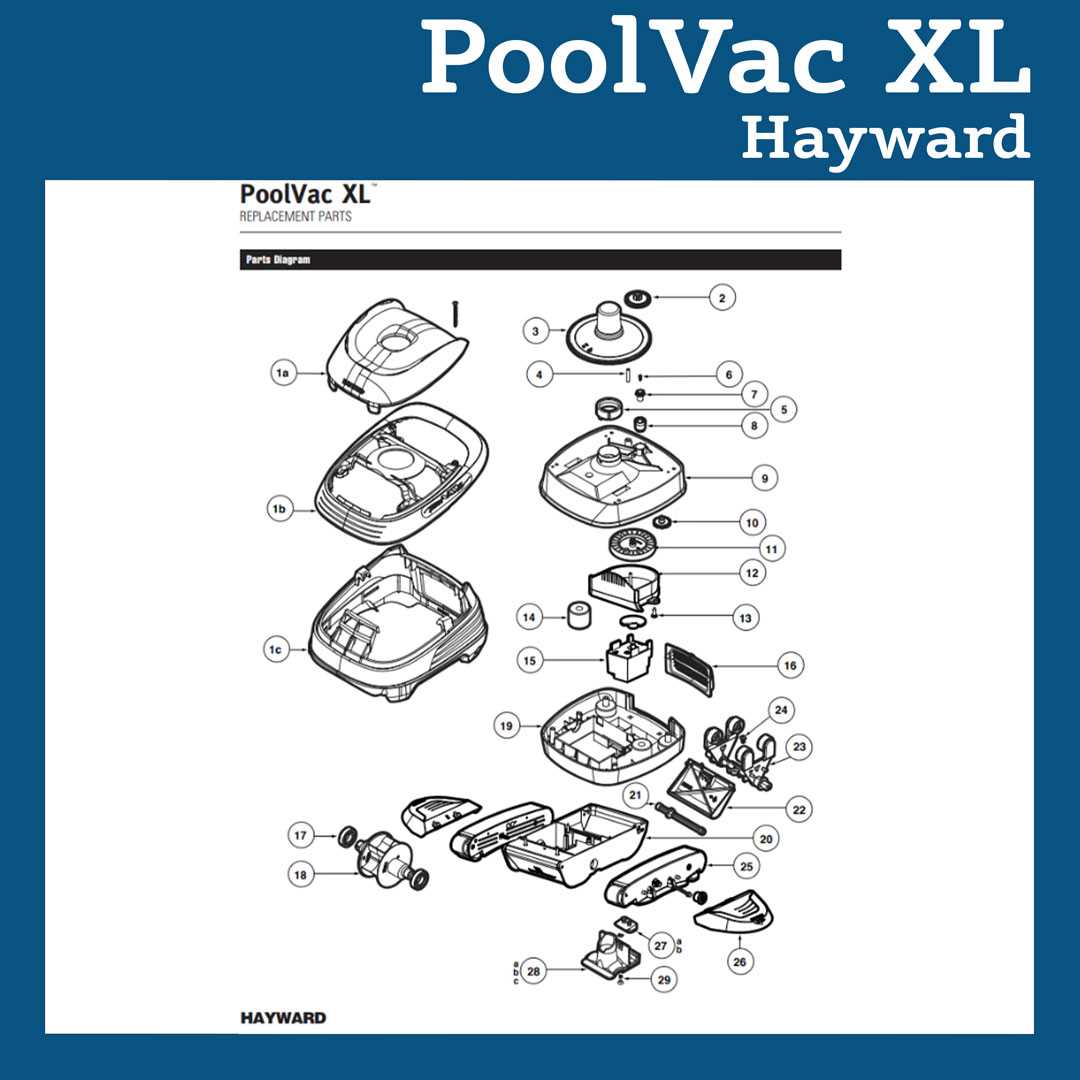

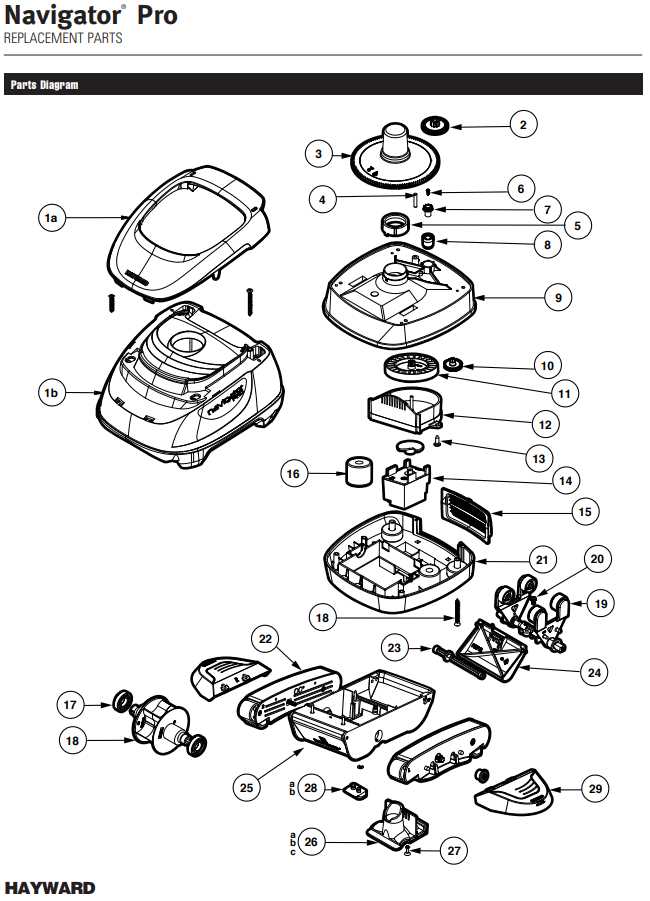

How to Read a System Layout

Understanding how to interpret a system layout is essential for effective maintenance and repairs. This visual representation shows the arrangement and connection of various components within the unit. By following a clear and logical structure, users can easily identify individual elements and their functions, which simplifies troubleshooting and part replacement.

Key Elements to Look For

When examining a system layout, certain key features will help guide you in understanding its structure. Pay attention to the following:

- Labels: Each component is often labeled to indicate its name or function.

- Connections: Arrows or lines may show how different elements are connected and how they interact with each other.

- Color Coding: In some diagrams, different colors may represent various system functions or types of components.

Step-by-Step Approach to Interpretation

To effectively read and use the layout, follow these steps:

- Start with the overview: Identify the main components to get a sense of the system’s general structure.

- Trace the connections: Follow the lines and connections to understand how the parts work together.

- Check the labels: Look for any labels or notations that describe each part’s function and specifications.

By following this approach, you can quickly become familiar with the layout and efficiently identify any issues. Knowing how to read the diagram is an invaluable skill for troubleshooting and maintaining the system in peak condition.

Common Component Issues

Even with regular maintenance, components in any system may experience issues over time. Recognizing these common problems early can prevent major malfunctions and ensure smooth operation. This section highlights typical issues that users encounter with various system elements and offers insights on how to address them effectively.

Temperature Regulation Problems

One of the most frequent issues is the failure to maintain consistent temperature levels. This can be caused by a malfunction in the temperature control unit, sensor issues, or problems with the heating element itself. When this occurs, the system may not heat efficiently or may overheat, causing potential damage to other components.

Airflow and Circulation Failures

Another common issue is poor airflow or circulation. Blockages in ducts or filters, faulty fans, or damaged circulation pumps can lead to inefficient operation and reduced performance. Proper airflow is crucial for the system’s overall efficiency, so addressing any circulation issues quickly can prevent further damage to the components.