When working with any portable generator, knowing the exact arrangement of its components is crucial for proper maintenance and repair. A clear breakdown of the system helps identify each part’s function and potential issues that could arise. This knowledge can ensure the longevity and efficiency of your equipment.

Accurate identification of each individual piece can make troubleshooting much easier, especially when dealing with malfunctions or wear. Whether you’re performing a routine check-up or replacing a specific component, understanding how everything fits together is essential for a successful repair.

Familiarizing yourself with the layout will not only save time but also prevent costly mistakes. A well-structured guide provides the necessary details to assist with any adjustments or upgrades you may need to make. With the right information at hand, you’ll be able to handle repairs more effectively and confidently.

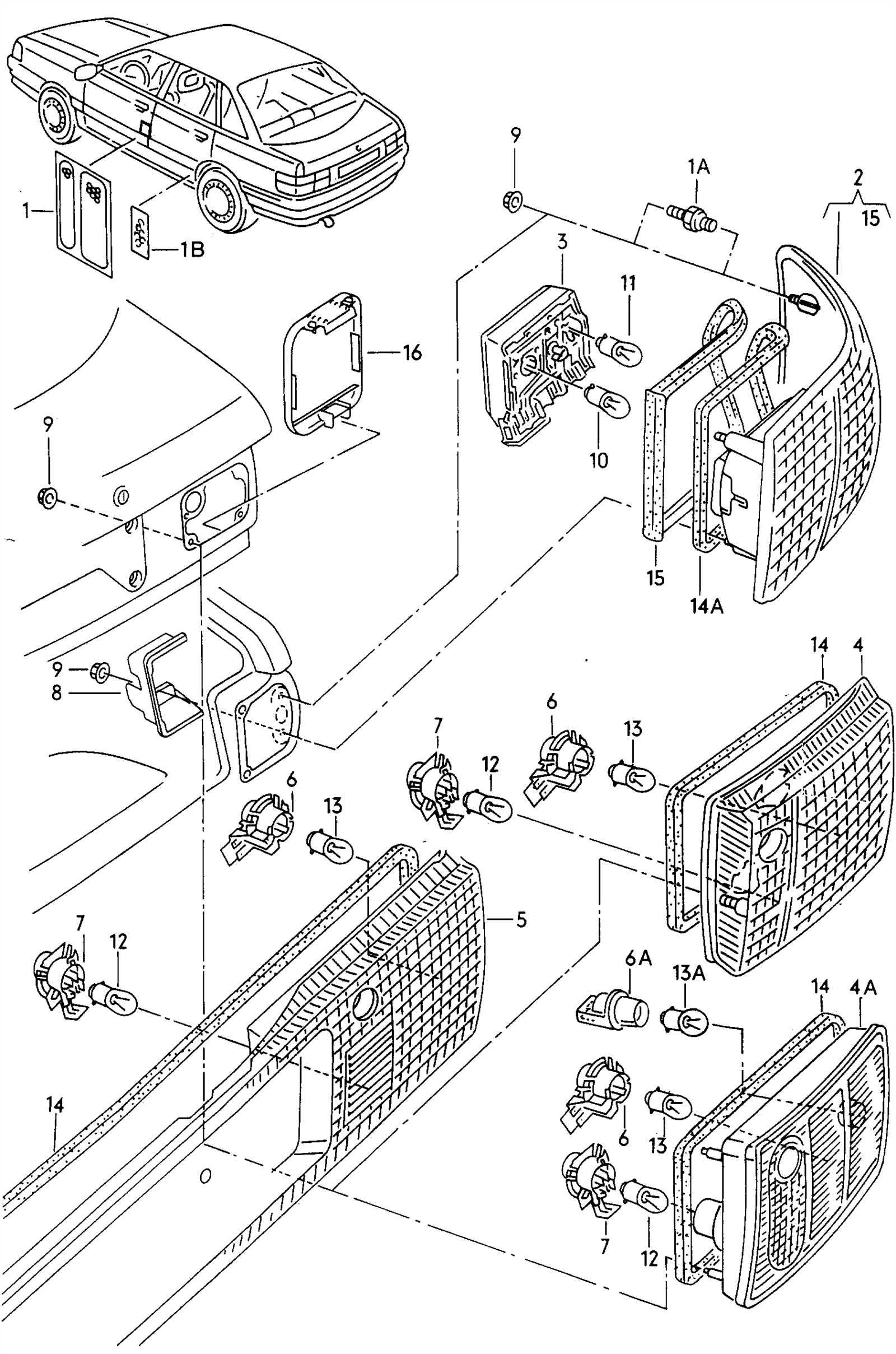

Understanding Generator Component Layout

In any power generator, the arrangement and connection of the different components are vital for its proper functioning. Each element has a specific role and must be in the correct position to ensure smooth operation. A clear layout helps users quickly identify and address issues when performing maintenance or repairs.

Knowing how each part is positioned in relation to others is essential for troubleshooting. Whether it’s the engine, the electrical system, or the exhaust components, understanding their placement simplifies diagnosis and speeds up the repair process. This knowledge also helps in preventing common mistakes during assembly or disassembly.

Properly visualizing the component layout also aids in upgrades or modifications. When adding new features or replacing worn-out parts, understanding the existing configuration ensures compatibility and optimal performance. A well-detailed layout is key to making informed decisions on maintenance tasks.

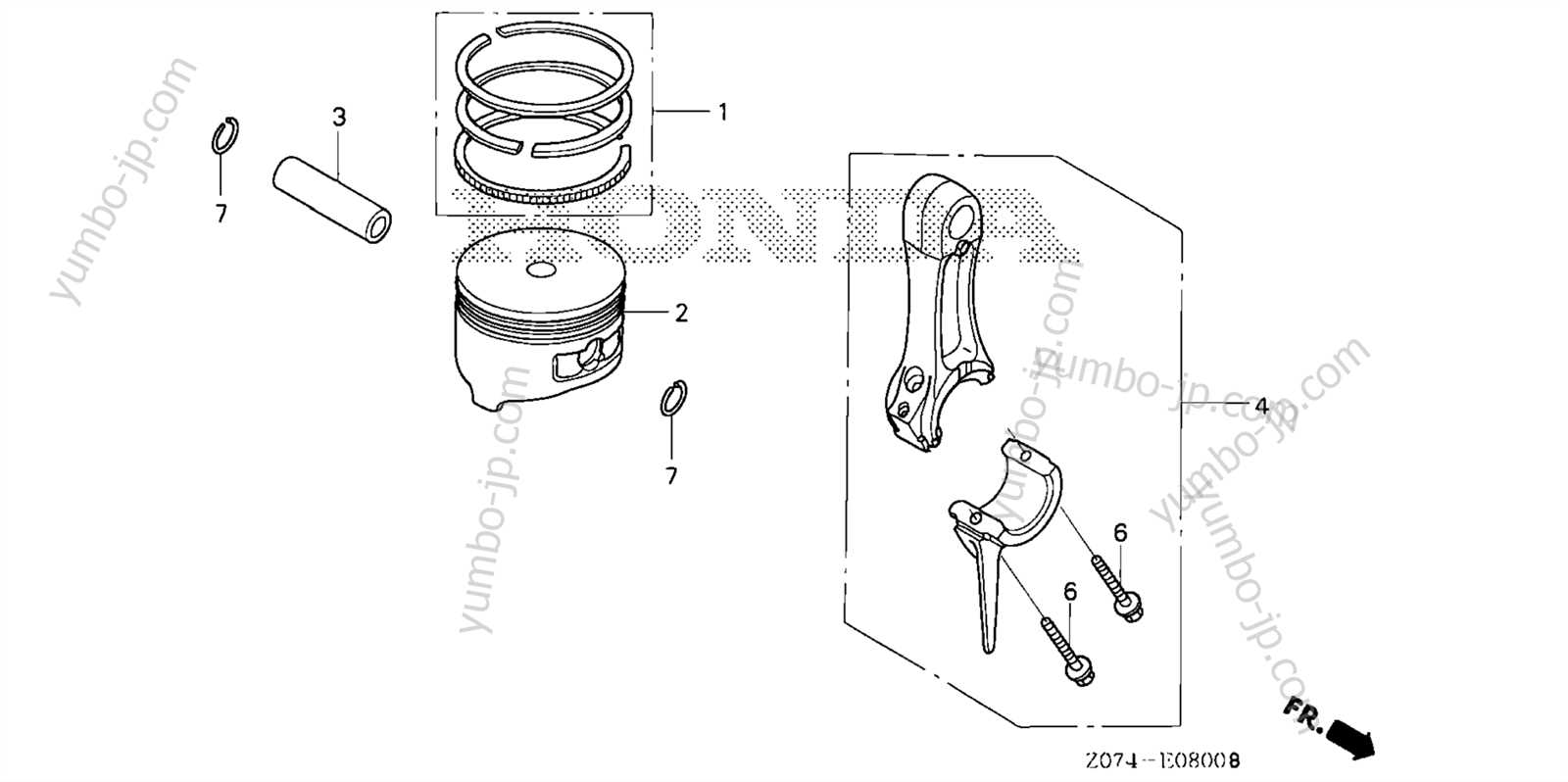

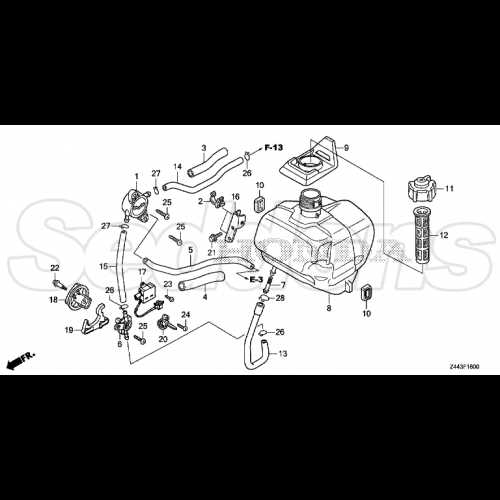

Key Components of the Generator

Every portable generator consists of several critical elements that work together to produce reliable power. These parts serve various functions, from generating electricity to maintaining engine efficiency. Understanding the role of each component is essential for troubleshooting and maintenance.

The engine is at the heart of the system, providing the necessary power to run the entire unit. It is typically fueled by gasoline or another energy source and requires proper care to ensure smooth operation. Additionally, the fuel tank plays a vital role in supplying the engine with fuel, making it crucial to monitor for leaks or blockages.

The electrical system converts mechanical energy into usable electrical power. This system includes various components such as the alternator, which generates electricity, and the circuit breaker, which ensures safety by preventing overloads. Proper understanding of these components allows for efficient troubleshooting and helps extend the lifespan of the generator.

How to Use the Component Layout

Understanding how to read and interpret a component layout is essential for any repair or maintenance task. This layout serves as a visual map of the entire system, allowing users to identify each piece and its location. By familiarizing yourself with the diagram, you can streamline the repair process and avoid unnecessary errors.

Start by locating the major elements of the system, such as the engine, electrical components, and fuel system. These are usually labeled clearly, making it easy to identify their specific roles. Then, follow the connections between components to understand how each part interacts with the others. This will help you identify potential issues faster, especially when diagnosing malfunctions.

Once you’re familiar with the layout, use it to find the exact replacement part needed for repairs or upgrades. The layout often includes part numbers and other helpful details, which make it easier to order the correct components. Overall, mastering the use of the layout can save time and improve the efficiency of any maintenance work.