Understanding the internal structure of any generator is essential for proper maintenance and repair. By examining how each part fits into the whole, users can identify potential issues and make informed decisions about repairs or replacements. A comprehensive guide to the different components reveals not only their functions but also their relationship to one another.

Each generator consists of numerous interconnected parts, with some playing a critical role in its overall performance. From the engine to the electrical system, knowing the specific function of each component allows users to troubleshoot effectively. Having access to a clear and detailed layout can significantly simplify the maintenance process, ensuring the device operates smoothly for years to come.

In this article, we will walk you through the essential parts of your generator, offering valuable insights into their roles and how they contribute to the overall system. Understanding these connections can help prevent common issues and improve the longevity of your equipment.

Understanding Generator Component Layout

To effectively manage the operation and maintenance of a generator, it’s important to grasp how each component interacts within the system. Each section has its role, contributing to the machine’s efficiency and functionality. Familiarizing yourself with the structure ensures that repairs, upgrades, and troubleshooting become more manageable tasks.

Key System Elements

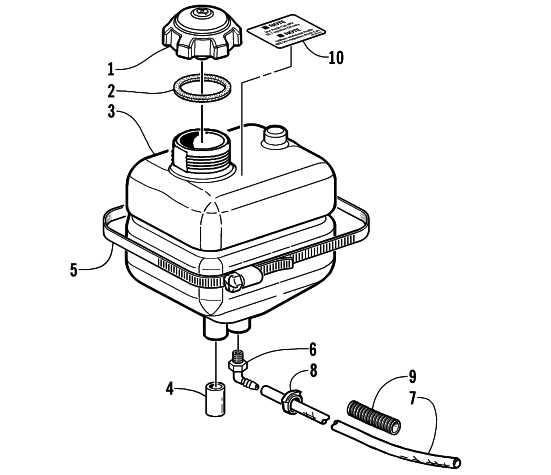

The internal structure of the generator is made up of several key elements, such as the engine, electrical components, and fuel systems. Each of these parts serves a specific function, from generating power to converting energy and delivering it to the necessary outlets. Understanding how these parts work together helps you recognize where issues may arise and how to fix them more effectively.

Component Interconnections

In addition to individual parts, it’s crucial to understand how they are connected. The interrelations between parts determine how efficiently the entire system functions. For example, the ignition system relies on the fuel and electrical components to operate correctly. Recognizing these relationships ensures better diagnosis and maintenance strategies, preventing costly repairs down the road.

Key Parts and Functions Explained

Understanding the core components of a generator and their specific roles is essential for optimal operation. Each part has a unique function that contributes to the overall performance and reliability of the system. By familiarizing yourself with these critical elements, you can ensure that your equipment functions efficiently and address any issues promptly when they arise.

Power Generation System

At the heart of the generator lies the power generation system, which consists of the engine and alternator. The engine provides the mechanical energy needed to drive the alternator, which then converts this energy into electrical power. This system is crucial for the generator’s ability to produce consistent and reliable power for external use.

Fuel and Electrical Systems

The fuel system stores and delivers the necessary fuel to the engine, while the electrical system controls and distributes the generated power. The fuel system typically includes components such as the fuel tank, filter, and pump, ensuring that the engine operates smoothly. The electrical system includes the ignition system, battery, and control panel, all of which are essential for starting, running, and managing the generator’s output.

Assembly and Maintenance Insights

Proper assembly and maintenance are essential for ensuring the longevity and reliable operation of any generator. Understanding how each component fits together and how to maintain them is key to preventing common issues and ensuring optimal performance over time. Regular upkeep and attention to detail during assembly can save both time and money on repairs.

Assembly Best Practices

When assembling a generator, it’s important to follow manufacturer guidelines carefully. Each component should be positioned and connected precisely to ensure smooth operation. Proper tightening of bolts, correct alignment of parts, and secure wiring can prevent mechanical failures and electrical issues down the line. Taking time during the assembly process ensures the generator runs efficiently from the start.

Maintenance Recommendations

Routine maintenance is crucial to keeping the generator in top working condition. Regularly checking the oil, fuel levels, and air filters can prevent wear and tear on critical components. It’s also important to inspect electrical connections for signs of corrosion and ensure that the cooling system is functioning properly to avoid overheating. Following a consistent maintenance schedule helps avoid costly breakdowns and prolongs the life of the equipment.