Understanding the internal structure of gardening machinery is essential for effective maintenance and repair. By familiarizing yourself with the different elements and how they work together, you can ensure the longevity of your tools. This section will provide an overview of essential components, their functions, and tips for maintaining them.

From the engine to the cutting mechanisms, every part plays a crucial role in achieving optimal performance. Proper knowledge helps in diagnosing issues early and making necessary adjustments to keep everything running smoothly. Regular upkeep and accurate troubleshooting are key to preventing breakdowns and improving efficiency.

Understanding the Honda FG110 Tiller Parts

Every piece of outdoor equipment is made up of various components that work together to perform specific functions. When you understand the individual elements, their purpose, and how they interact, it becomes easier to manage the maintenance and repair of the machine. This knowledge ensures that the equipment operates efficiently for longer periods and reduces the likelihood of unexpected issues.

In any mechanized tool, key sections such as the power source, handling system, and control mechanisms are integral to the device’s overall performance. Each of these units is essential for making sure the machine operates at peak capacity. The relationship between these parts, and their specific roles, is vital for the machine’s functionality, which is why understanding them is crucial.

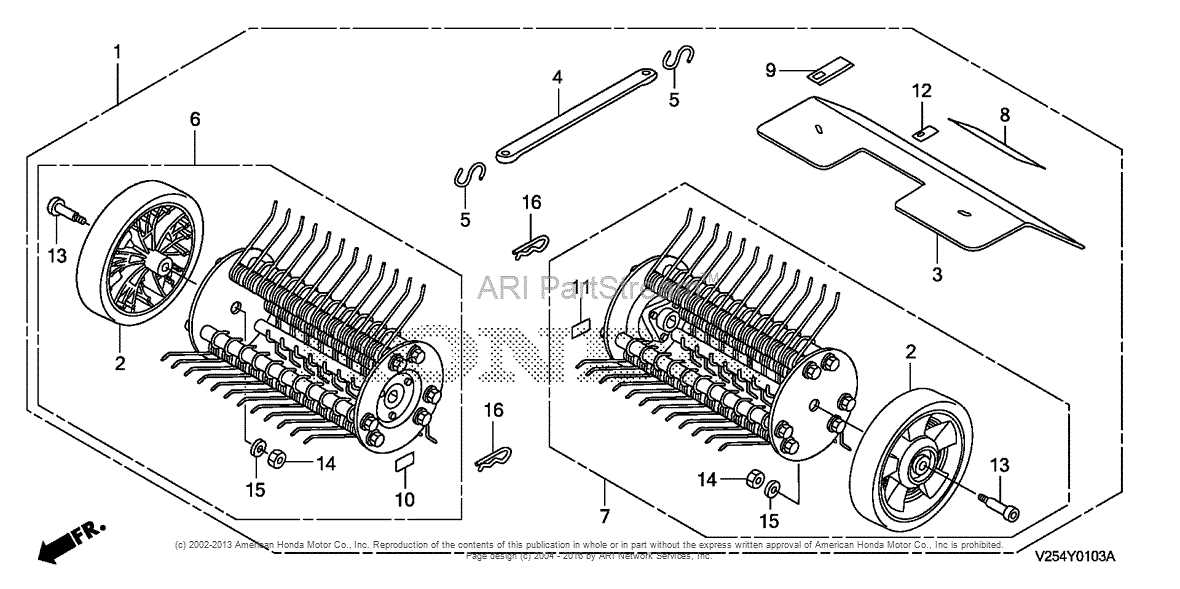

Key Components of the Honda FG110 Tiller

The performance of any mechanical equipment depends on the functionality of its primary components. These essential parts work in harmony to provide the desired results, whether for digging, tilling, or maneuvering. Understanding how each element contributes to the overall operation allows users to maintain and troubleshoot the machine effectively.

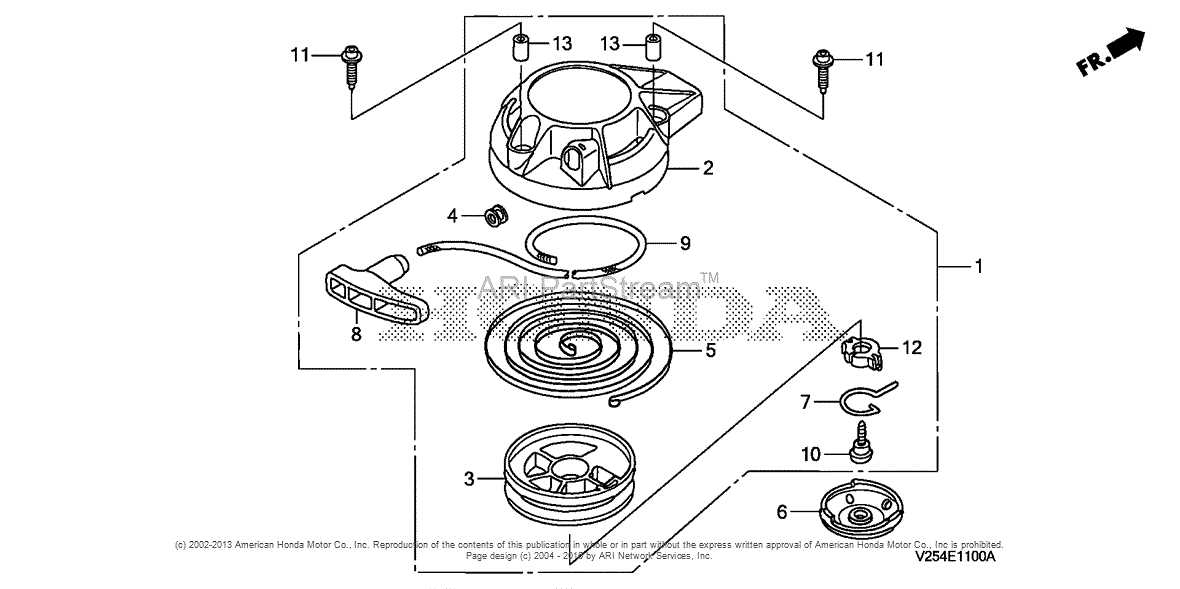

Engine and Power System

The engine serves as the heart of the equipment, providing the necessary power to operate all the other functions. It converts fuel into energy, driving the rotating mechanism and other elements of the machine. Regular maintenance of this component, such as checking oil levels and cleaning air filters, is essential for its longevity.

Control and Handling Mechanisms

The controls allow the user to steer and manage the equipment efficiently. Handles, throttle systems, and transmission parts are responsible for adjusting speed and direction. Ensuring these components are free of obstructions and properly lubricated can prevent issues during operation and improve ease of use.

Maintenance Tips for Honda FG110 Tiller Parts

Proper care and regular maintenance are crucial for ensuring the longevity and efficient operation of any mechanical equipment. By following basic upkeep routines and addressing small issues before they become bigger problems, users can avoid costly repairs and extend the lifespan of their machines. In this section, we’ll explore some essential tips for keeping your equipment in top condition.

Regular Cleaning and Inspection

One of the easiest yet most effective maintenance tasks is keeping the machine clean. After each use, remove dirt and debris from the exterior, especially around moving parts. Check for wear and tear, and ensure that components like air filters, spark plugs, and fuel lines are free of blockages or damage. Regular inspections help identify minor issues early, preventing larger malfunctions later on.

Lubrication and Fluid Checks

Lubricating the moving parts, such as the throttle controls and transmission system, is key to smooth operation. Regularly check the oil levels, and ensure they are at optimal levels to avoid engine strain. Replacing fluids at recommended intervals helps maintain peak performance and prevents internal parts from wearing out prematurely.