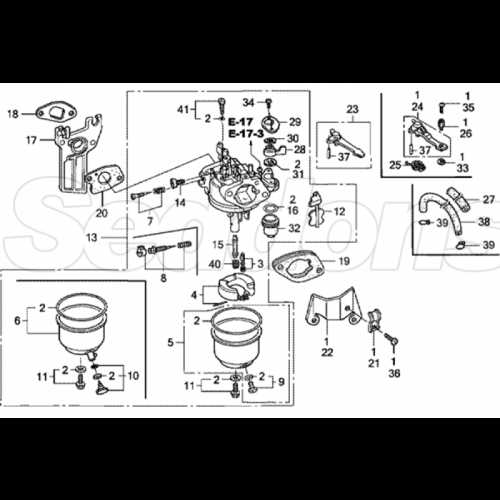

Knowing the internal structure of any small engine is crucial for effective maintenance and troubleshooting. Understanding how various components interact can significantly improve repair accuracy and prolong the machine’s lifespan.

In this section, we will explore key elements of small engines, focusing on their functionality and common issues. Having a clear overview of each part helps when it comes time for replacements or repairs, ensuring smoother operation and reduced downtime.

Accurate knowledge of engine mechanics will enable you to quickly identify problems, saving both time and money. Whether you’re a hobbyist or a professional, mastering these details is essential for maintaining peak performance.

Understanding Engine Components

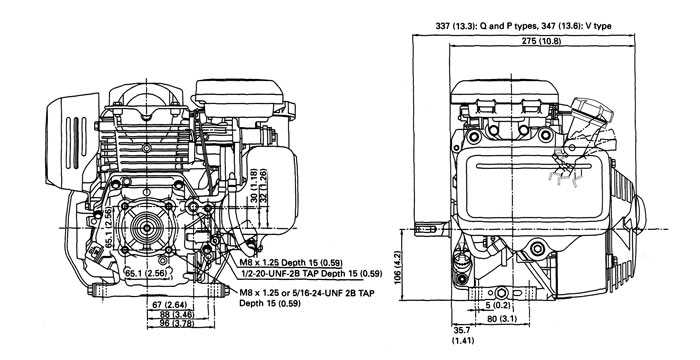

To effectively maintain a small engine, it’s essential to understand the roles of its various components. Each part works in unison to ensure the engine operates smoothly, and recognizing their functions can make troubleshooting and repairs more efficient. From fuel delivery to exhaust systems, each element contributes to the overall performance and longevity of the engine.

The powerplant consists of several key sections such as the combustion chamber, cooling system, and ignition components. Each plays a vital role in energy production, heat management, and the smooth running of the system. Familiarity with these sections allows for faster diagnostics and better-informed repair decisions.

By learning how each component interacts within the engine, users can prevent common issues and ensure optimal performance. Understanding the assembly helps in identifying when something is malfunctioning and pinpointing the source of a problem with greater accuracy.

Step-by-Step Guide to Engine Components

To ensure the longevity and smooth functioning of a small engine, it’s important to have a clear understanding of how each component fits together and operates. A methodical approach to inspecting and replacing parts can prevent unnecessary breakdowns and improve overall performance.

Disassembling the Engine

Start by carefully removing the external coverings and components to gain access to the internal parts. Make sure to take note of how each piece is connected, as this will help during reassembly. Pay close attention to the condition of the parts as you remove them, checking for signs of wear or damage that might need replacement.

Reassembling and Testing

After replacing any worn-out components, begin reassembling the engine step by step. Ensure all connections are secure and that each part is properly aligned. Once reassembled, test the engine to confirm everything is working as expected, making any adjustments if necessary.

Common Issues and Part Replacements

Small engines, like any mechanical systems, can experience wear and tear over time. Recognizing common issues early and knowing which components to replace can save both time and money. Understanding these problems allows for quicker repairs and ensures the engine continues to run efficiently.

Engine Starts but Runs Rough

If the engine starts but operates unevenly, the issue could be related to the carburetor or fuel system. A clogged carburetor or a fuel filter in poor condition can cause erratic performance. Replacing these parts and ensuring the fuel system is clean can restore the engine’s smooth operation.

Excessive Smoke and Poor Power Output

Excessive smoke from the exhaust and a noticeable decrease in power may point to a problem with the piston rings or cylinder. These parts wear out over time, reducing compression and engine performance. Replacing the piston rings or checking the cylinder for damage is essential to resolving this issue and restoring power.