When working with small engines, it’s crucial to understand the intricate components that keep them running smoothly. Knowing how each part functions can help with troubleshooting, maintenance, and ensuring long-lasting performance. Proper knowledge of these mechanisms allows users to handle common issues and perform basic repairs with confidence.

In this guide, we will explore the essential elements that make up the engine’s fuel delivery system. By examining how these components interact, you can identify potential problems and learn how to maintain them effectively. Proper care and timely replacements of these elements are key to keeping the engine in top condition, ensuring reliability and efficiency during use.

Whether you’re a beginner or have some experience with engine repair, this article will help you gain a better understanding of the key components that contribute to an engine’s operation. With clear explanations and practical tips, you’ll be prepared to tackle any maintenance tasks with ease.

Understanding the Engine’s Fuel Delivery System

The heart of any small engine’s fuel mechanism lies in the system that controls the mixture of air and fuel, delivering it to the combustion chamber. This process is essential for efficient engine performance and smooth operation. Understanding how each component within this system works together can help diagnose issues and ensure optimal functionality. Knowing the individual elements involved will allow you to recognize when something isn’t functioning as it should and take corrective actions.

How the Fuel System Functions

At its core, the fuel delivery mechanism regulates the flow of air and fuel, ensuring the right balance for ignition. This system is composed of multiple components that each play a specific role, from air intake to fuel flow regulation, ensuring the engine runs with maximum efficiency. If any one of these elements is not working correctly, the engine may face issues such as poor fuel efficiency, erratic idling, or difficulty starting. Proper knowledge of the system helps identify where problems may occur and aids in quicker resolutions.

Key Elements to Focus On

Focusing on the components within the fuel system, it is important to understand how each part contributes to the overall functionality. Air intake, throttle control, and fuel delivery components each affect performance. Familiarity with these parts makes it easier to spot issues like clogging, wear, or malfunction, all of which could lead to decreased engine performance. Regular maintenance and proper care can keep these elements working seamlessly for long-term engine reliability.

Identifying Key Parts in the Diagram

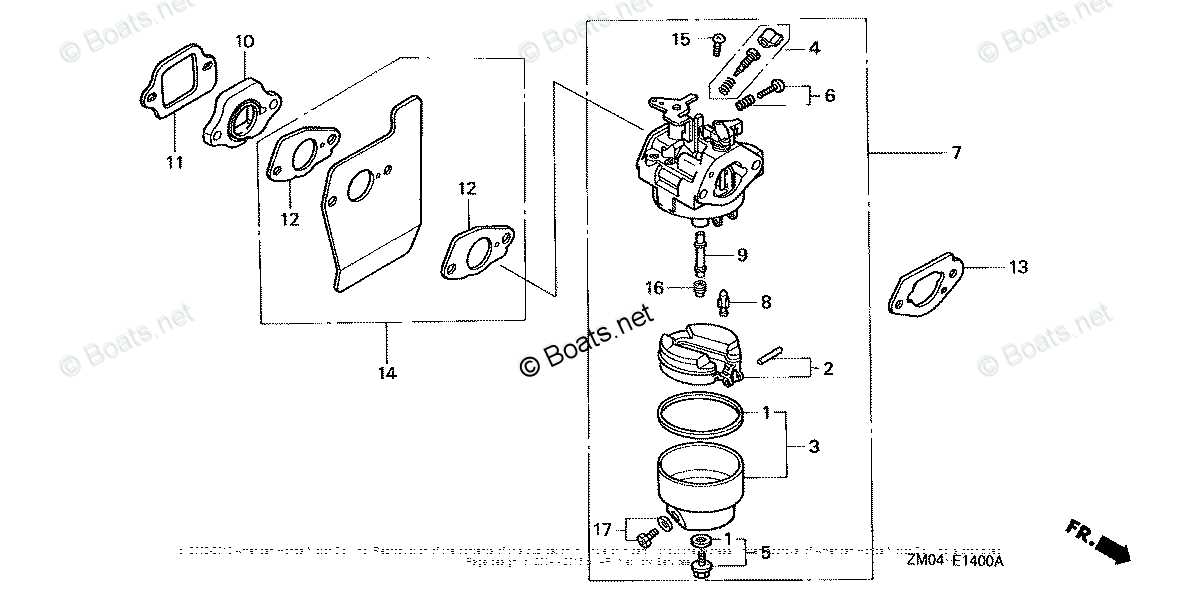

Understanding the components that make up the fuel system of an engine is crucial for proper maintenance and repair. Each element has a specific function that contributes to the overall performance. Being able to identify these components allows for quicker troubleshooting and efficient repairs. Knowing the role of each piece helps you determine which ones might be causing issues when the engine is not running as expected.

When examining the layout of the fuel mechanism, focus on key components such as the air intake, throttle valve, fuel valve, and flow regulators. Recognizing these parts will help you understand their interaction and pinpoint problems that affect the engine’s performance. Pay attention to components that regulate air and fuel mixture, as they are essential for smooth engine operation.

Additionally, it’s important to be familiar with smaller but equally significant pieces like seals, springs, and adjustment screws. These parts play a role in maintaining the correct balance and preventing leaks or other issues that could arise over time. Regular inspection of these elements is necessary for long-term engine health.

How to Maintain Your Carburetor Efficiently

Maintaining the fuel delivery system of an engine is essential for its longevity and reliable performance. Regular upkeep prevents common issues such as clogging, fuel leaks, and inefficient combustion. By following a few simple maintenance practices, you can ensure the system operates smoothly and efficiently, reducing the risk of costly repairs and ensuring the engine runs at its best.

Start by performing routine cleaning to remove any buildup of dirt or fuel residues that could obstruct fuel flow. Check for any signs of wear or corrosion on the components, especially seals and gaskets, and replace them as needed. This helps prevent leaks and ensures that the engine maintains proper pressure for efficient combustion.

Another important aspect of maintenance is adjusting the fuel mixture and idle settings. Over time, these settings may need fine-tuning to ensure the right balance of air and fuel. Regularly inspecting the system and making adjustments ensures that the engine runs smoothly and consumes fuel efficiently, improving overall performance.