Understanding the key elements that make up your small engine is crucial for maintaining its performance and longevity. Whether you’re a seasoned mechanic or a beginner, having a clear reference for assembly and disassembly is invaluable. Proper identification and knowledge of each part can save time and effort when repairing or replacing worn-out components.

Each engine features a unique arrangement of essential parts that work together to power your machine efficiently. With the right guidance, you can quickly identify which components need attention, ensuring that your equipment runs smoothly for years to come. This guide will provide you with the necessary insights to keep your engine in optimal condition, with a focus on clarity and ease of use.

Proper maintenance and repair techniques are vital for extending the life of any engine. By learning to navigate the structure and functions of individual parts, you gain the confidence to perform repairs yourself. This will not only enhance the machine’s reliability but also reduce downtime and costly professional services.

Understanding the Engine Components

Every small engine consists of a variety of components that work in unison to ensure smooth operation. Recognizing these elements and their functions is essential for effective maintenance and troubleshooting. By understanding how each part contributes to the overall system, you can better manage repairs and replacements, ensuring your engine runs optimally.

Key Elements of the Engine

The engine’s core components include the fuel system, ignition system, and the mechanical parts responsible for motion. The fuel system stores and delivers gasoline to the engine, while the ignition system generates the spark needed for combustion. Mechanical parts, such as the piston and crankshaft, transform the energy produced by the combustion process into usable power, driving the engine’s operation.

Recognizing Wear and Tear

Over time, certain engine components may wear down, leading to reduced efficiency or malfunction. Common signs of wear include difficulty starting the engine, unusual noises, or poor fuel efficiency. Identifying which component has been affected allows for targeted maintenance, helping you avoid more significant issues and ensuring your engine continues to perform at its best.

How to Identify Engine Components

Correctly identifying the components of your small engine is the first step towards effective maintenance and repair. Whether you’re replacing a worn-out element or performing routine checks, knowing the specific names and functions of each component can save time and prevent mistakes. The process involves familiarizing yourself with the structure of the engine and understanding how each piece fits into the system.

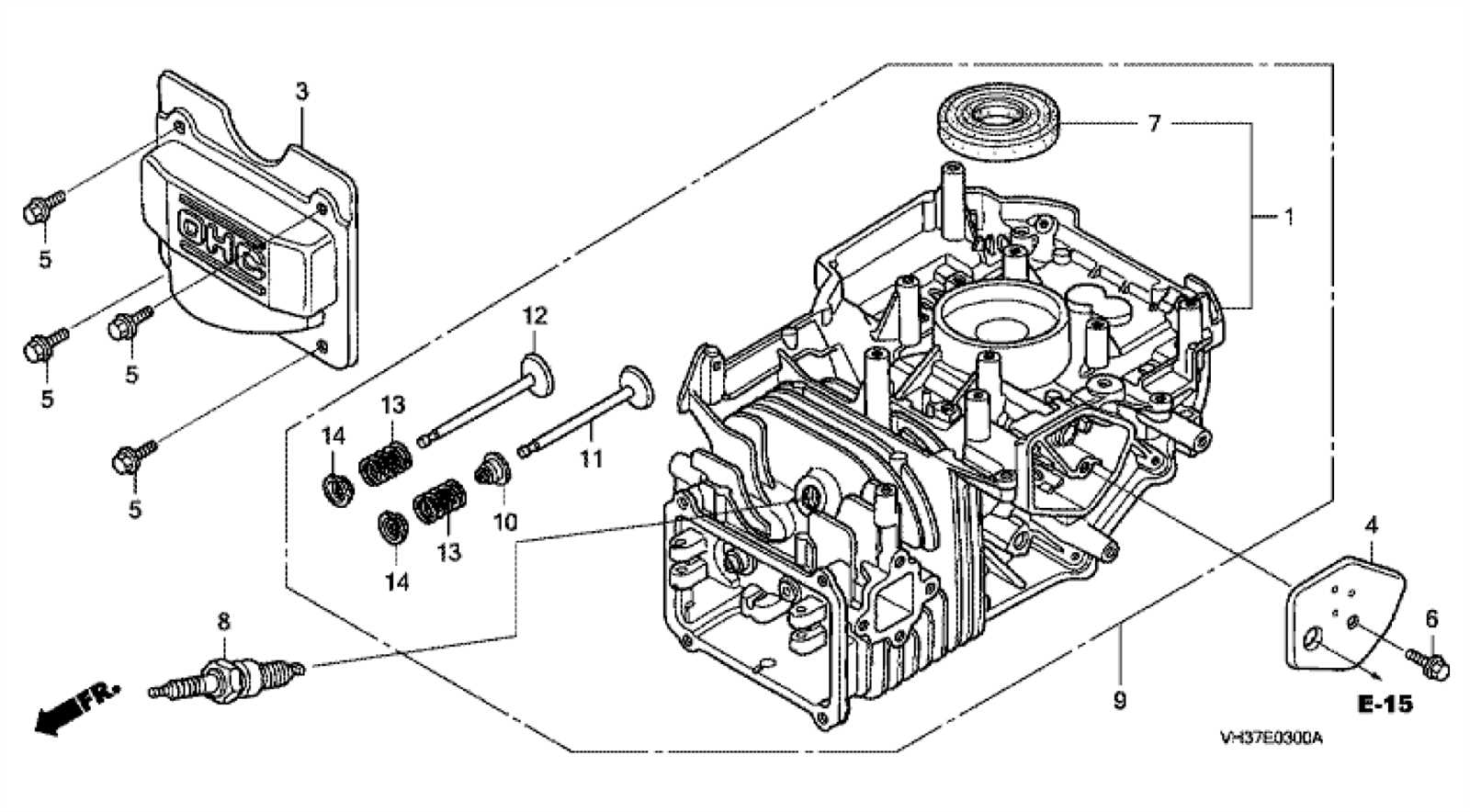

Visual Inspection and Reference Materials

Start by conducting a visual inspection, noting the shape, size, and position of the various components. Having a clear reference, such as a manual or a detailed guide, will help in cross-referencing each part’s role and location. Diagrams or schematics that outline the layout of the engine can provide a clearer understanding, allowing you to identify specific parts more easily.

Utilizing Labels and Part Numbers

Many components have labels or part numbers that are printed directly on them. These identifiers are extremely helpful when trying to pinpoint a replacement part. Checking the manufacturer’s documentation for these details ensures that you are sourcing the correct items, which is critical for ensuring compatibility and proper function.

Replacing Components in the Small Engine

Replacing worn or damaged elements of your small engine is essential for maintaining its efficiency and performance. Whether you’re addressing a specific issue or performing preventative maintenance, knowing how to properly remove and install new components is key. The process typically involves careful disassembly, identification of faulty parts, and correct reassembly to ensure smooth operation afterward.

Preparation and Safety Precautions

Before starting any replacement, ensure the engine is turned off and has cooled down. Disconnecting the spark plug and draining any fuel are also critical steps for safety. Use the right tools to avoid damaging surrounding parts and ensure a secure fit when installing new components. Having a clean workspace and following manufacturer guidelines will make the process smoother and reduce the risk of error.

Step-by-Step Replacement Process

Begin by removing any external covers or barriers that obstruct access to the damaged components. Carefully detach the faulty part, paying attention to how it is connected. Replace it with the new component, making sure all connections are secure and aligned properly. Test the engine after reassembly to ensure the new part functions as expected and the machine is running smoothly.