When maintaining and repairing your cleaning machine, knowing its internal structure is crucial. Familiarizing yourself with its individual components can significantly ease troubleshooting and replacement processes. Each element of the system plays a vital role in its performance, and understanding their functions can save you time and effort in the long run.

In this guide, we will break down the essential elements of this type of machine. By learning how the pieces interact and understanding their specific tasks, you can effectively manage repairs or upgrades. Recognizing each part’s role will also allow you to make informed decisions when looking for replacements or accessories.

Properly interpreting the assembly layout is key to efficient maintenance. Once you know how to read the technical drawings, it becomes easier to identify issues and pinpoint what needs attention. Whether you’re fixing a malfunction or simply performing routine care, this knowledge is invaluable for any machine owner.

Understanding the Honda GCV190 Pressure Washer

Every mechanical system, especially those designed for cleaning, consists of various components working in harmony to deliver efficient performance. Knowing how these elements interact is essential for users seeking to keep their equipment in optimal condition. Understanding the underlying structure and function of the system is the first step toward effective maintenance and troubleshooting.

The engine, pump, and other integral components are designed to work seamlessly together, with each part playing a unique role in generating power and directing flow. From the engine’s combustion to the final action of the water stream, every element must function properly to ensure that the machine delivers reliable results. Recognizing how these components operate in unison helps users make informed decisions about repairs or replacements when needed.

Additionally, it’s important to familiarize yourself with the layout of the system. Understanding the arrangement of each piece allows you to identify potential issues early, as well as perform routine checks to maintain longevity. A clear understanding of the machine’s design simplifies troubleshooting and ensures you can resolve issues with minimal hassle.

Common Parts of the Honda GCV190 Pressure Washer

Understanding the key components of any machine is essential for proper maintenance and repair. In this section, we will explore the main elements that make up the cleaning system. These components work together to ensure smooth operation and effective performance, and knowing them can help identify any issues that may arise.

Engine and Fuel System

The engine is the heart of the machine, generating the necessary power for operation. It typically includes a fuel tank, carburetor, and ignition system. These parts work together to convert fuel into mechanical energy. Regular checks on the fuel system are essential to prevent clogging and ensure the engine runs efficiently. Keeping the engine in good condition is crucial for maintaining the overall performance of the device.

Water Pump and Nozzle

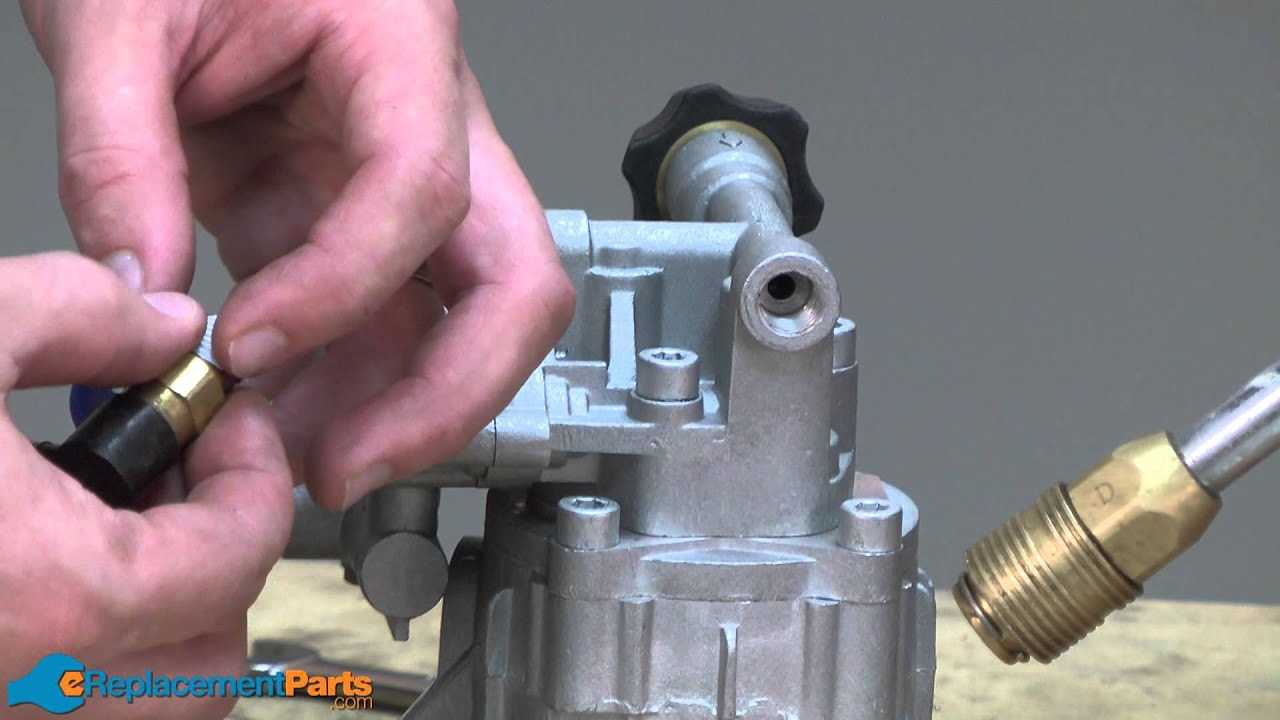

The pump is responsible for generating the pressure that drives the water through the hose and nozzle. It plays a crucial role in ensuring that the water flow is consistent and strong enough to handle cleaning tasks. The nozzle, which is attached to the end of the hose, controls the spray pattern. Together, these components ensure the effective distribution of water, making cleaning tasks more efficient. Regular inspection and maintenance are key to preventing issues such as leaks or reduced pressure.

How to Read the Pressure Washer Parts Diagram

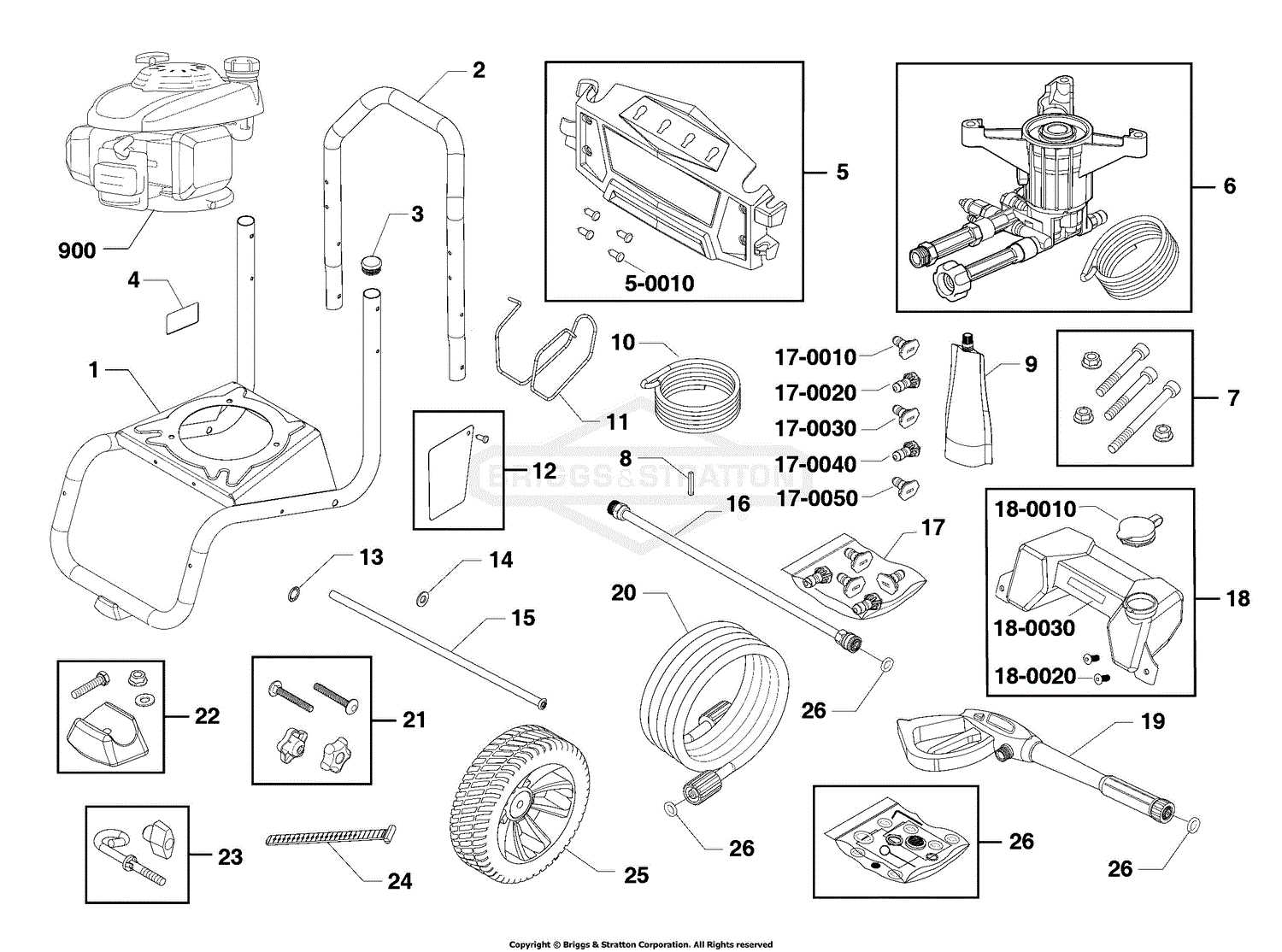

Interpreting technical illustrations is an important skill for anyone involved in maintenance or repairs. These detailed drawings help users understand the structure and connection of various components within a machine. By learning to read and interpret these schematics, you can quickly identify issues, locate specific parts, and streamline the repair process.

Understanding Symbols and Notations

Technical illustrations often include symbols and notations that represent different elements of the system. Each symbol is carefully chosen to provide a visual reference for users, making it easier to understand how the components are connected. It’s essential to familiarize yourself with these symbols and the corresponding part numbers, which will help you locate the right parts when needed. Pay close attention to the labels and arrows that indicate flow directions, as they are key to understanding the system’s operation.

Locating and Identifying Components

Once you understand the symbols, the next step is to identify the components on the diagram. Each part is usually numbered, and the numbers correlate with a list of parts or a parts catalog. This allows you to easily identify the components you need to repair or replace. By tracing the connections between these parts, you can see how they work together and ensure that everything is in the right place. Always double-check that the part numbers match your machine model to avoid ordering incorrect components.