When it comes to maintaining and repairing outdoor power equipment, having a clear understanding of its internal structure is crucial. Each machine consists of various components that work together to ensure smooth operation. Whether you’re a seasoned technician or a DIY enthusiast, identifying and understanding these elements is the key to keeping your device running efficiently.

In this section, we will explore how to recognize different parts and their functions. With proper knowledge, you can easily diagnose issues and perform necessary repairs or replacements. A thorough comprehension of each piece will save time and prevent unnecessary expenses.

Knowing your equipment’s inner workings will allow you to make informed decisions about maintenance. Familiarizing yourself with the layout of its components gives you the confidence to handle even more complex tasks. Embrace the process of learning and empower yourself to keep your equipment in top condition.

Understanding the Internal Components

To maintain and repair any outdoor power tool effectively, it’s essential to familiarize yourself with its essential elements. Each machine is made up of multiple interconnected parts, each performing a specific function to ensure optimal performance. Recognizing these components and understanding their role can significantly improve your ability to troubleshoot and repair the device as needed.

Key Elements of the System

Among the most important features are the engine, fuel system, and electrical components. Each of these plays a vital role in how the machine operates, with the engine providing the necessary power, the fuel system ensuring a steady supply, and the electrical system enabling operation and control. Understanding how these systems interact is critical to diagnosing any potential issues.

Identifying and Replacing Faulty Components

Being able to identify when a specific element is malfunctioning allows you to take appropriate action before problems escalate. Whether it’s a simple maintenance task like replacing a filter or a more complex repair involving the electrical wiring, knowing how to disassemble and examine each part carefully is crucial. Proper identification of defective parts prevents unnecessary repairs and enhances the device’s longevity.

How to Identify Key Components

Proper identification of the internal elements of your equipment is the first step in successful maintenance and repair. Knowing each component’s function and location makes it easier to spot any issues and determine what needs attention. This process also allows you to ensure that only the correct replacements are made when necessary.

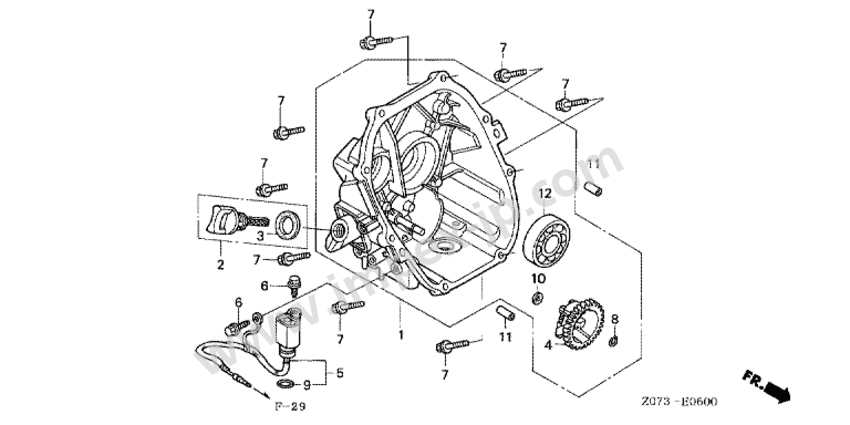

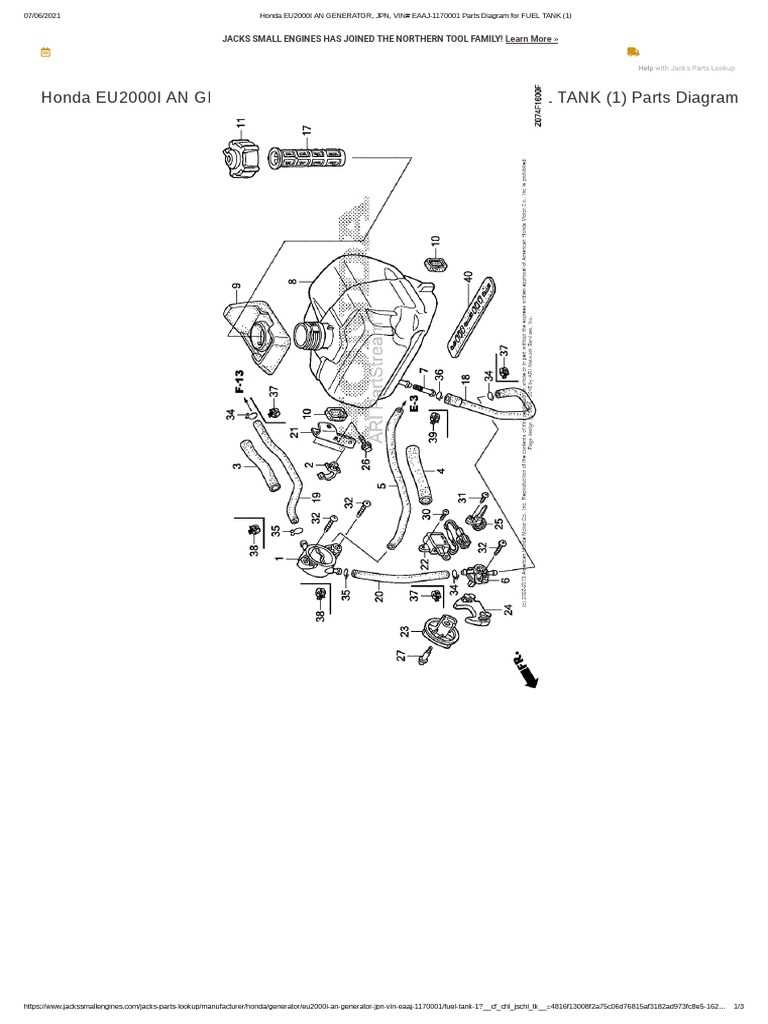

Start by consulting the user manual or reference guides that provide an overview of the equipment’s internal structure. These guides typically include a clear outline of each part, often accompanied by visual aids or labels to make identification easier. Understanding these references helps you quickly locate a malfunctioning piece and act accordingly.

Additionally, take note of any distinguishing features such as shape, size, and material. Many parts have unique characteristics that make them easier to identify. With the right knowledge, you can efficiently maintain the machine, replacing only the necessary parts and avoiding unnecessary repairs.

Maintenance Tips for Key Components

Proper upkeep of your equipment’s internal elements is crucial for ensuring long-lasting performance and reliability. Regular maintenance not only prevents sudden malfunctions but also extends the life of the machine. By performing routine checks and addressing minor issues early on, you can avoid costly repairs and downtime.

Start by keeping the engine clean and free of debris. Over time, dirt and dust can build up, reducing efficiency and potentially causing overheating. Regularly check and replace filters as needed, ensuring that air and fuel flow smoothly. Additionally, inspect the electrical system for any loose connections or wear on wires that could lead to operational issues.

Another key aspect of maintenance is lubrication. Keep the moving parts well-oiled to reduce friction and prevent wear. Be sure to follow the manufacturer’s guidelines for the right type and amount of lubricant. Consistent attention to these areas ensures that your machine runs smoothly and is ready when needed.