When working with small engines, knowing the individual components and their functions is crucial for efficient maintenance and troubleshooting. A clear illustration of each part helps owners understand how everything fits together and operates smoothly. Understanding this breakdown makes repairs more manageable and enhances the overall performance of the machine.

Efficient maintenance starts with recognizing the key elements that make up the engine. This knowledge allows users to quickly identify potential issues and address them before they lead to more significant damage. Whether it’s for routine servicing or troubleshooting, knowing where each part resides and how it functions contributes to a longer engine lifespan.

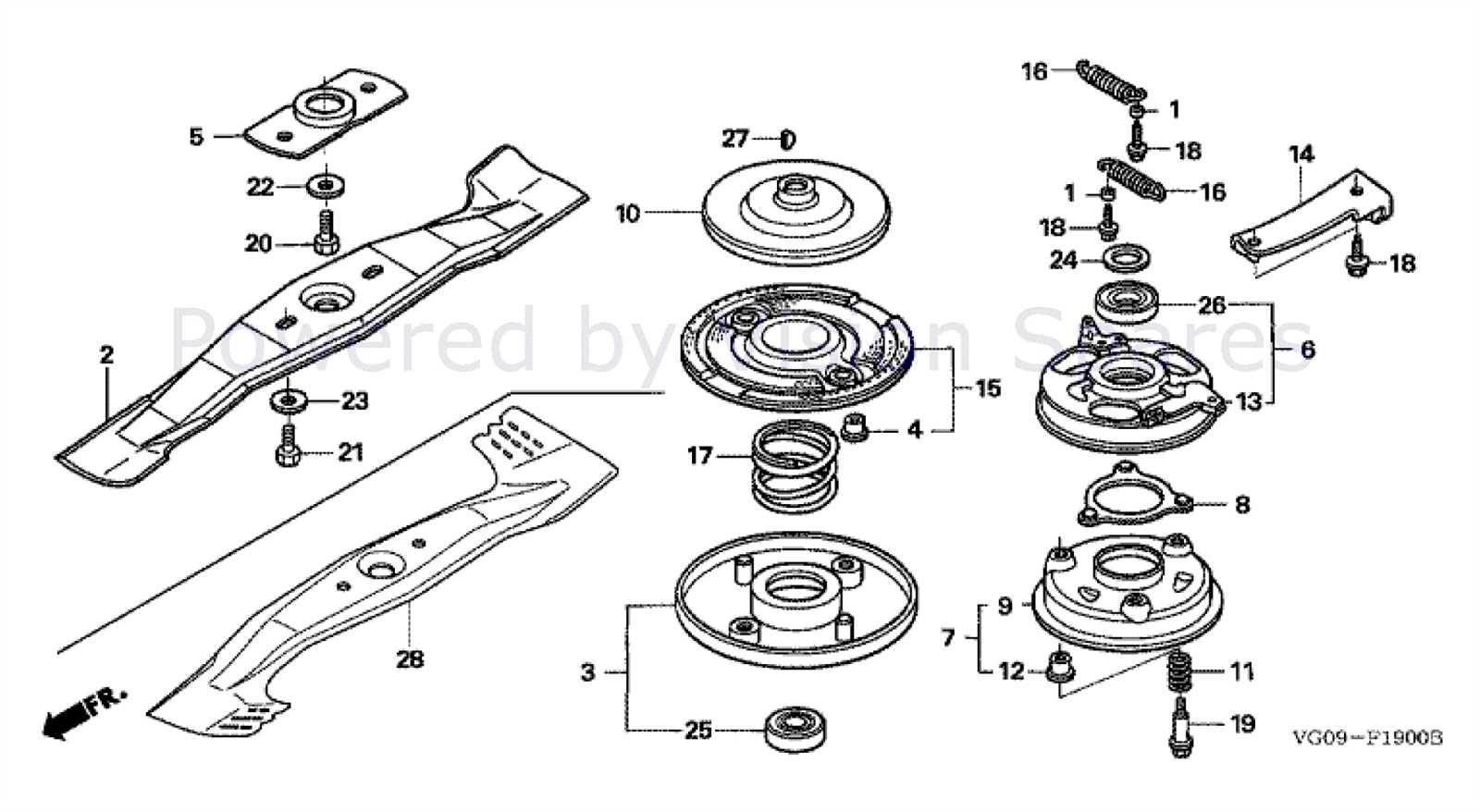

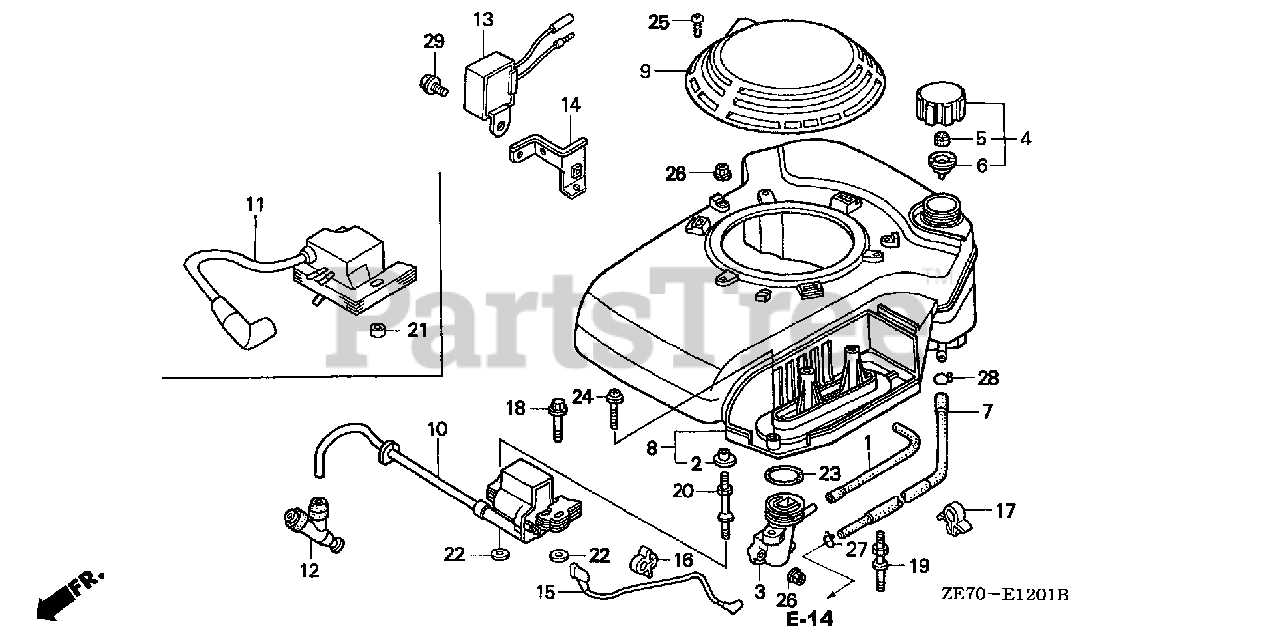

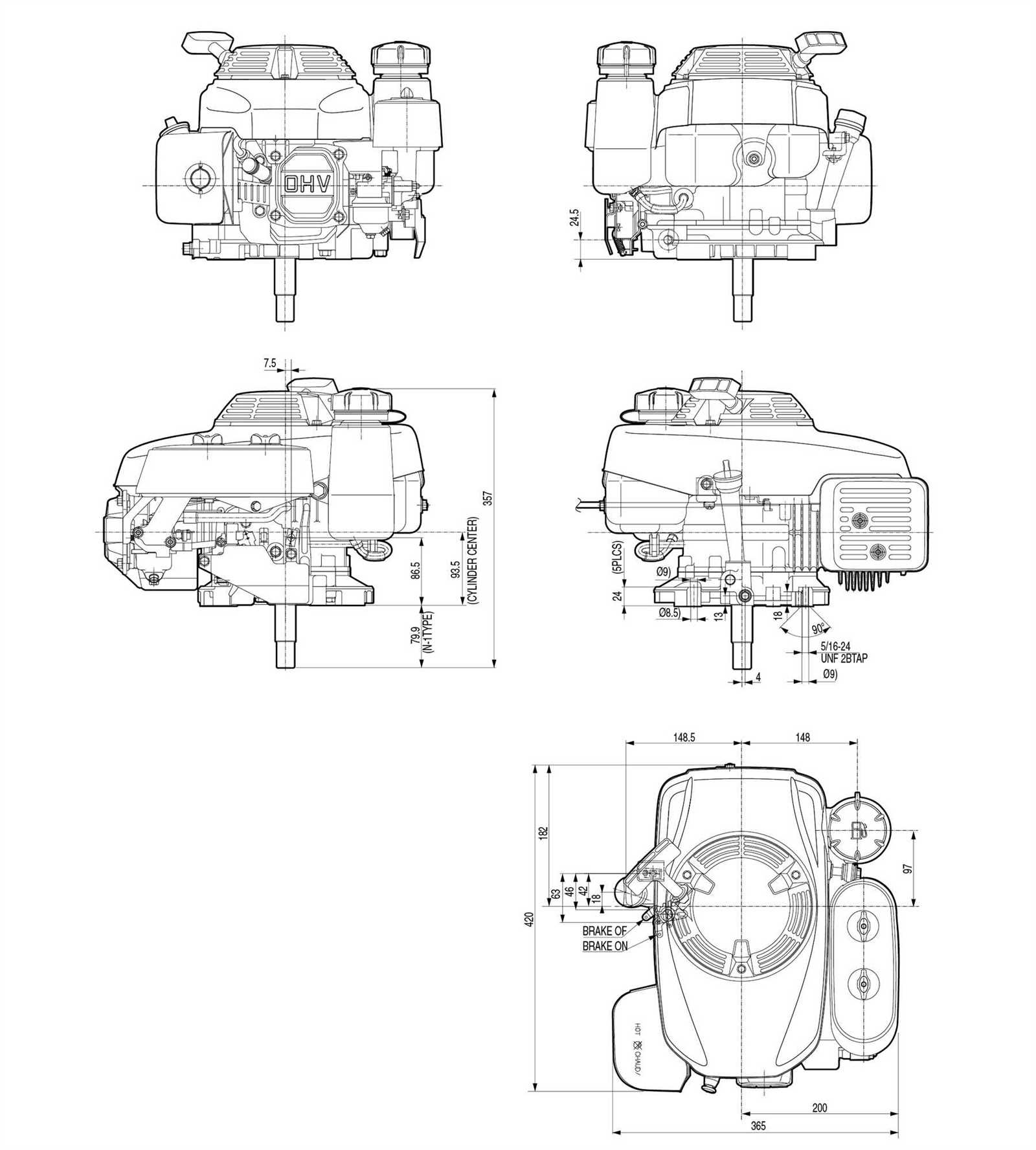

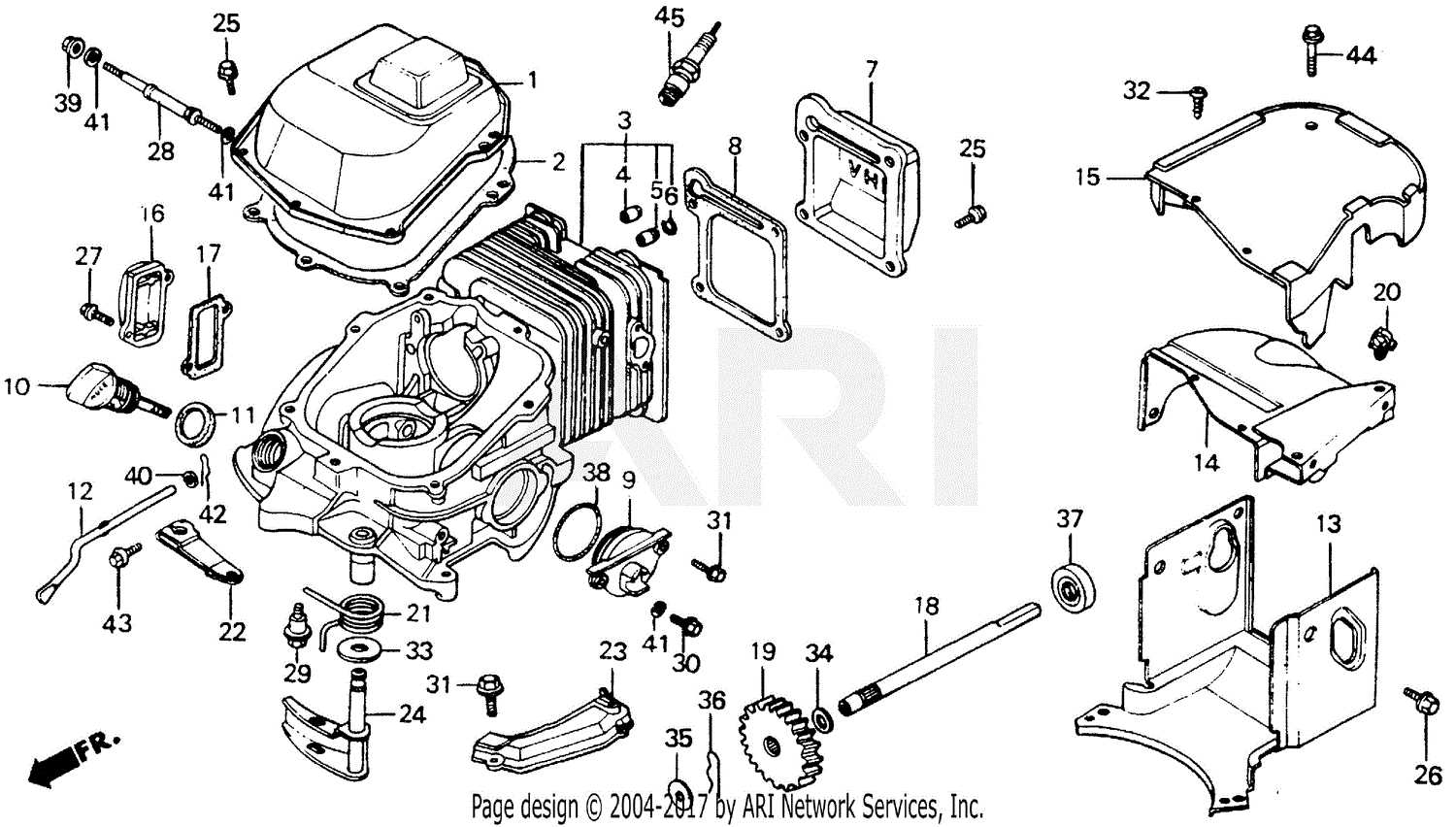

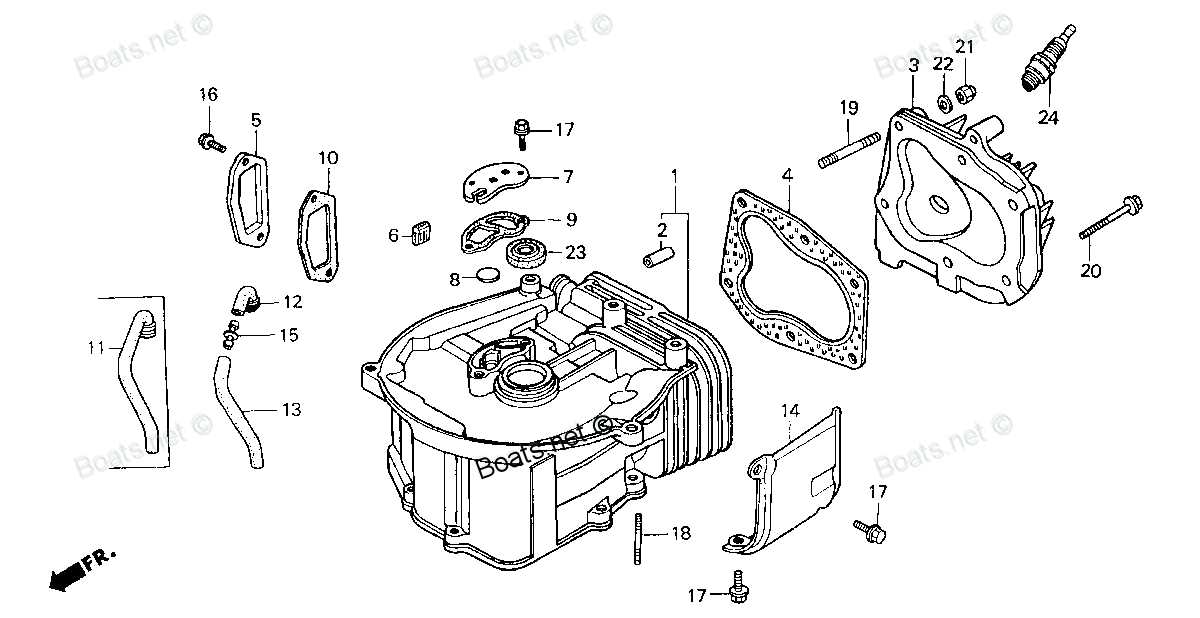

Technical diagrams serve as valuable tools in this process, offering a visual map of all components. With accurate visual aids, you can perform repairs with precision, making sure everything is correctly aligned and functioning as intended.

Understanding the Engine Components

Each small engine is made up of a variety of essential elements that work together to ensure proper function. To maintain peak performance and prevent potential issues, it’s important to familiarize yourself with these key components. Identifying how each part interacts with others helps in diagnosing problems and completing repairs more efficiently.

The engine’s functionality depends on the seamless cooperation of various systems. These include elements responsible for energy generation, air and fuel management, and mechanical movements. Below are the main categories of components that contribute to the overall operation:

- Fuel System: Includes the fuel tank, fuel pump, carburetor, and fuel lines that work together to deliver the correct amount of fuel to the engine.

- Ignition System: Comprising the spark plug, ignition coil, and flywheel, this system ensures the engine starts and runs smoothly by creating the necessary spark for combustion.

- Air and Exhaust System: Features like the air filter, intake valve, and exhaust valve control airflow into and out of the engine, optimizing fuel efficiency and emissions.

- Mechanical Components: These include the crankshaft, pistons, and camshaft, which work in unison to transfer energy and keep the engine operating smoothly.

- Lubrication System: Essential for maintaining engine longevity, this system reduces friction and wear by ensuring the moving parts are well-oiled.

By understanding the function of each of these components, you can more effectively troubleshoot issues and perform maintenance tasks. Proper care and attention to each part will contribute to the overall efficiency and reliability of the engine, extending its service life and preventing major repairs.

Detailed Breakdown of Engine Components

To fully comprehend how an engine functions, it is crucial to have an in-depth understanding of its individual elements. Each component plays a specific role, and when they all work together, they allow the engine to perform efficiently. This breakdown will focus on the most important elements that contribute to the engine’s operation.

Fuel and Air Management

The fuel and air systems ensure that the engine receives the proper mixture for combustion. This includes components that regulate fuel intake, air filtration, and the delivery of both to the combustion chamber.

- Fuel Tank: Stores fuel to be delivered to the engine.

- Carburetor: Mixes air with fuel to create the right ratio for combustion.

- Air Filter: Prevents dirt and debris from entering the engine by filtering the air before it reaches the combustion chamber.

Ignition and Mechanical Components

The ignition system is responsible for starting the engine and ensuring it runs smoothly. In addition, the mechanical parts transfer power from the fuel to the moving parts of the engine.

- Ignition Coil: Generates the spark needed for combustion when the engine starts.

- Flywheel: Stores rotational energy and helps to maintain consistent engine speed.

- Crankshaft: Converts the reciprocating motion of the piston into rotational motion, powering the machinery.

- Pistons: Move up and down within the engine to compress the fuel mixture and create power.

These components must be carefully maintained and periodically inspected to ensure optimal performance. By understanding each part’s function and its role in the overall system, you can more effectively troubleshoot issues and conduct necessary repairs.

How to Use the Engine Breakdown Illustration

Visual references are invaluable when working with small engines, offering clear insights into the arrangement and function of each component. Using an illustration effectively allows you to pinpoint parts quickly, making maintenance and repair tasks more manageable. Understanding how to read and utilize these illustrations can save time and ensure accuracy during repairs.

When using an engine illustration, start by identifying the main sections of the engine. Each part will be labeled, providing a clear view of its position and connection to the other elements. Carefully follow the lines or arrows that indicate how parts are assembled or interact with each other. This approach helps in troubleshooting issues and ensures you can quickly locate the part that needs attention.

Another helpful method is to use the reference to verify part numbers, which can guide you in ordering replacements or comparing different models. When working on disassembly or assembly, refer back to the visual guide to confirm the correct placement of each component and ensure everything is reassembled properly. By following these steps, you can work more efficiently and reduce the risk of errors during engine maintenance.