When it comes to vehicle functionality, the smooth operation of various moving elements is crucial for both convenience and safety. A well-designed system ensures that all parts work together seamlessly, providing an effortless user experience. This section will explore the internal structure of a specific mechanism and how its various elements contribute to its overall performance.

Identifying key components within the system can be essential for maintenance and troubleshooting. Understanding how each part fits into the larger picture allows for more efficient repairs and replacements, reducing downtime and potential costs. From structural elements to smaller functional pieces, all components play a vital role in ensuring proper operation.

Proper upkeep involves knowing when and how to address wear and tear, as well as recognizing signs of malfunction. Whether you’re performing routine checks or handling specific repairs, this guide provides essential insights into the individual elements that keep the system running smoothly.

Understanding the Vehicle Access Mechanism

In modern vehicles, the accessibility system plays a significant role in providing ease of entry and exit. The design of these systems combines various mechanical and electrical components that work in unison to offer smooth and reliable operation. These systems are particularly useful in larger vehicles where traditional methods of entry might not be as practical. Understanding how these mechanisms function is key to proper maintenance and repair.

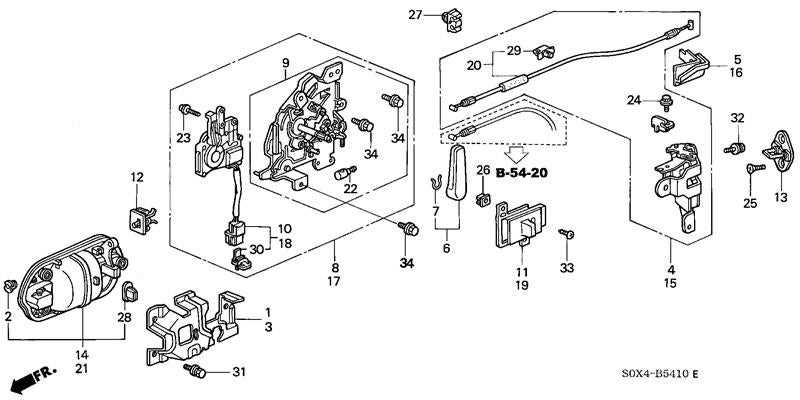

Key Components of the Access Mechanism

At the heart of the system, several key elements ensure the functionality of the access mechanism. These components include guides, motors, and various locking mechanisms that help control movement. The integration of these parts allows for automated or manual operation, providing convenience in day-to-day use. Over time, wear and tear can affect these elements, leading to malfunctioning or failure, making it important to recognize each part’s role.

Maintenance and Troubleshooting Tips

Routine maintenance is essential to keep the access system working properly. Regular checks on mechanical components, such as tracks and rollers, can prevent damage before it becomes a larger issue. Additionally, ensuring that electrical systems are functioning, including sensors and motors, can help avoid disruptions in operation. Recognizing early signs of malfunction, such as strange noises or difficulty in operation, can make repairs more manageable and cost-effective.

Essential Parts of the Access System

Every vehicle access system consists of several crucial elements that work together to ensure smooth and reliable functionality. Understanding these components can help in diagnosing issues and performing effective repairs. Below is a breakdown of the key elements involved in the operation of this system.

Key Mechanical Components

The mechanical components play a vital role in enabling smooth movement and stability. These parts are responsible for guiding the mechanism and ensuring that it moves correctly. The primary mechanical elements include:

- Track and Rail System: Provides a pathway for the moving part, allowing it to travel smoothly back and forth.

- Rollers and Bearings: Facilitate the movement along the track, reducing friction and ensuring a smooth glide.

- Locking Mechanism: Keeps the system securely in place when it is closed or open, preventing unintended movement.

Electrical and Sensor Elements

Along with mechanical components, the electrical and sensor systems enhance the automation and safety of the access system. These include:

- Motor and Drive Assembly: Powers the movement of the system, enabling automatic operation when activated.

- Sensor System: Detects obstacles or obstructions, ensuring that the system operates without causing damage or injury.

- Wiring and Connectors: Facilitate the flow of electricity to various electrical components, ensuring they function as needed.

These combined elements form the foundation of a reliable and efficient access system. Regular inspection of each part can help maintain the performance of the system and prevent potential failures.

How to Identify Faulty Components

Recognizing when a mechanism is not functioning correctly is crucial for maintaining the overall performance of a vehicle. Identifying faulty components early can prevent further damage and reduce repair costs. Common symptoms like unusual sounds, difficulty in operation, or inconsistent movement often indicate underlying issues that need attention. Understanding the signs of malfunction and knowing where to look can make troubleshooting much easier.

Common Signs of Malfunction

Several indicators suggest that a component may be failing. These include:

- Unusual Noises: Grinding, squeaking, or clunking sounds can signal that internal parts, such as rollers or tracks, are damaged or misaligned.

- Uneven Movement: If the system moves sluggishly or gets stuck at certain points, it may indicate a problem with the track, bearings, or the motor.

- Unresponsive Operation: When the system fails to open or close properly, the issue might lie with the electrical components, such as sensors or the motor.

- Visible Wear or Damage: Cracked, bent, or broken components are clear signs that repairs or replacements are needed.

Steps for Diagnosing Issues

Once the symptoms are identified, it’s important to follow a systematic approach to pinpoint the faulty part. Begin by performing a visual inspection of the mechanical and electrical components. Check for misalignment, debris in the track, or visible damage to rollers and bearings. Test the electrical components, including sensors and the motor, to ensure they are working properly. If necessary, consult the system’s manual for specific troubleshooting steps related to your vehicle model.

Common Issues with Access Mechanisms

Over time, the moving systems within vehicles may experience various issues that affect their functionality. These problems can arise from mechanical wear, electrical malfunctions, or simple lack of maintenance. Identifying the most common issues early on can prevent further damage and ensure that the system continues to operate efficiently. Below are some of the frequent problems encountered with these access systems.

Mechanical Problems

Many issues related to movement and alignment are due to mechanical components. These often include:

- Track Obstructions: Dirt, debris, or foreign objects can block the movement along the track, causing the mechanism to jam or become uneven in operation.

- Worn Rollers: As the rollers age, they may lose their ability to glide smoothly, resulting in jerky or slow movement.

- Misalignment: The track or the moving part can shift out of alignment, leading to difficulty in opening or closing the system properly.

Electrical and Sensor Issues

In modern systems, electrical components play a significant role. Problems with these parts can disrupt automatic functions. Common issues include:

- Failed Sensors: Sensors are responsible for detecting obstructions and ensuring safety. When they malfunction, the system may fail to respond to nearby objects, posing a safety risk.

- Motor Failure: If the motor becomes damaged or worn, the system may struggle to operate or may stop functioning entirely.

- Electrical Wiring Problems: Loose, frayed, or corroded wires can interrupt the flow of power, leading to partial or complete failure of the system.

Regular maintenance and prompt attention to these issues can prevent more severe damage and ensure that the access system remains in optimal working condition.

Step-by-Step Repair and Maintenance Tips

To ensure the longevity and smooth operation of any vehicle mechanism, regular maintenance and timely repairs are essential. By addressing issues early on, you can avoid costly repairs and prevent more serious damage. Below are some practical steps to follow for maintaining and repairing the system effectively.

1. Inspect and Clean Regularly: One of the most straightforward ways to prevent malfunctions is through regular inspection. Check the tracks, guides, and moving components for any debris or buildup. Cleaning the system ensures smooth movement and minimizes wear on the parts. Use a soft cloth or brush to clear any dirt, and lubricate the moving elements with a silicone-based lubricant to keep them functioning smoothly.

2. Check Alignment: If the system is not opening or closing properly, misalignment may be the culprit. Carefully inspect the tracks and the components for any shifts or bends. If the parts are out of alignment, gently adjust them back into place. In some cases, this may require loosening screws or bolts, realigning the tracks, and then tightening the hardware securely.

3. Replace Worn or Damaged Components: Over time, some parts will inevitably wear out or become damaged. Commonly affected components include rollers, bearings, and motors. If you notice abnormal noises, sluggish movement, or difficulty in operation, these parts may need to be replaced. Consult your vehicle’s manual for the correct replacement components and ensure you install them following the recommended procedures.

4. Test Electrical Functions: If the system involves electrical elements such as motors or sensors, it’s important to test them periodically. Look for signs of wear on the wiring and check for any loose connections. If the motor isn’t functioning, it might need replacing. If the sensors aren’t detecting obstructions properly, recalibration may be necessary. Make sure the power supply is functioning before attempting electrical repairs.

5. Perform a Function Test: After maintenance or repairs, always conduct a test to ensure everything is working as it should. Open and close the mechanism several times to check for smooth operation, unusual sounds, or difficulty. If everything is functioning correctly, your maintenance has been successful.

By following these steps, you can ensure that the access system stays in good condition, improving both its reliability and longevity.