Maintaining small engines requires a clear understanding of their individual elements. Whether you’re a professional mechanic or a DIY enthusiast, knowing how each component fits together is crucial for effective maintenance and repair.

When working with these machines, it’s important to have a visual reference of the engine’s structure. By examining how the different sections are connected, you can better identify any issues and understand the proper steps to take for repairs or replacements.

Having a comprehensive visual guide can simplify complex tasks and ensure that repairs are done accurately. This will ultimately help you extend the life of your equipment and improve its performance.

Understanding the 18 HP Engine Components

Each engine is made up of several key components that work together to generate power. These parts, from the fuel system to the ignition mechanism, must function in harmony to ensure smooth operation. Gaining insight into their roles can make it easier to troubleshoot and maintain machinery.

The power generation system plays a critical role in the engine’s performance, converting fuel into mechanical energy. Other important elements include the air intake, exhaust system, and the crankshaft, each contributing to the engine’s efficiency and longevity.

Understanding how these components interact with each other helps identify potential problems and simplifies the repair process. Proper maintenance of each individual element ensures reliable operation and extends the life of your equipment.

How to Read the Parts Diagram

Understanding how to interpret technical illustrations is essential for anyone working with small engines. These visual references can significantly simplify the identification of components, their placement, and connections. By learning how to read these guides, you can efficiently perform maintenance and repairs.

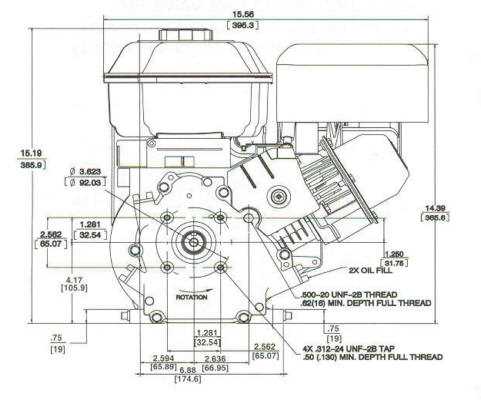

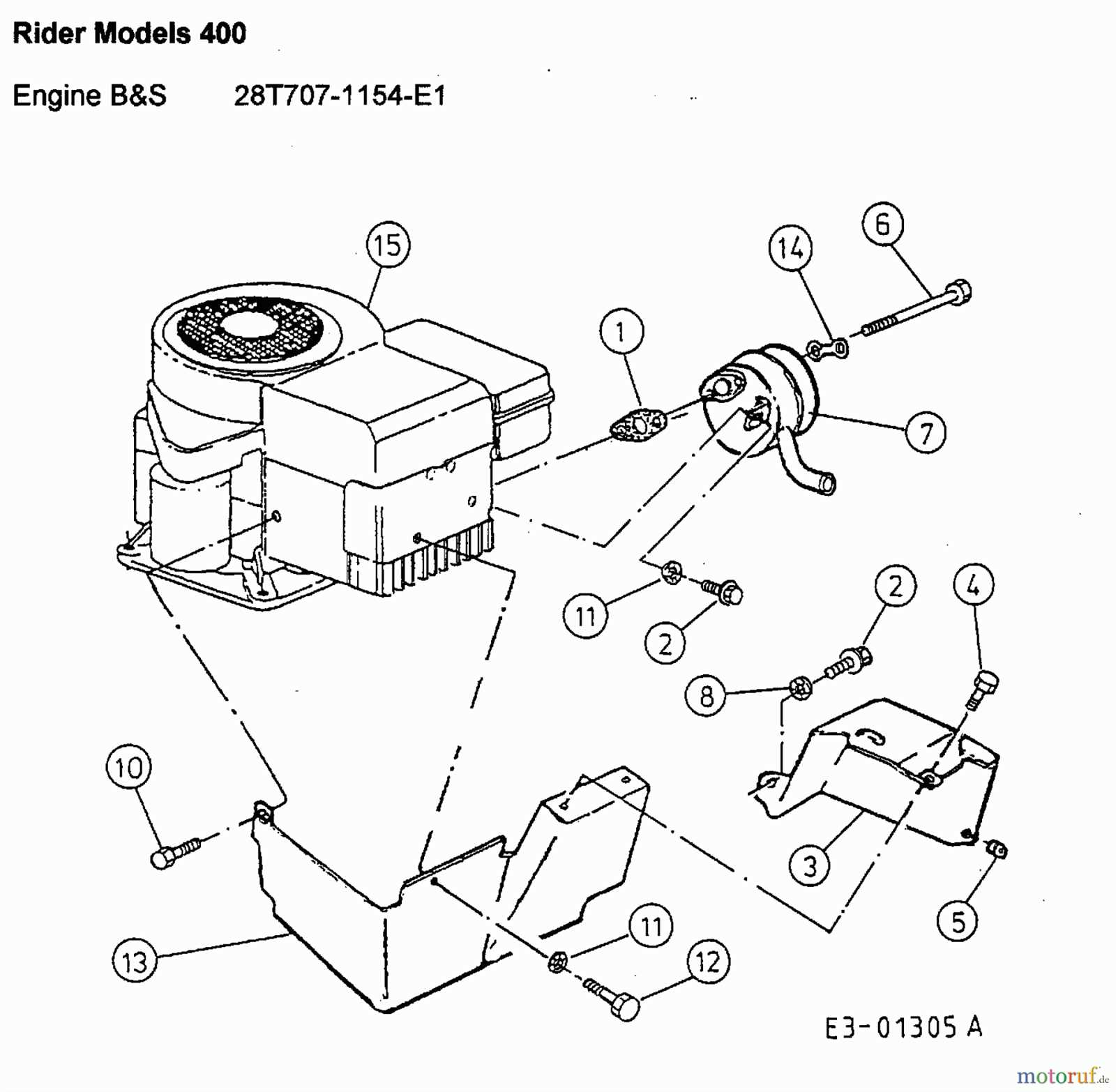

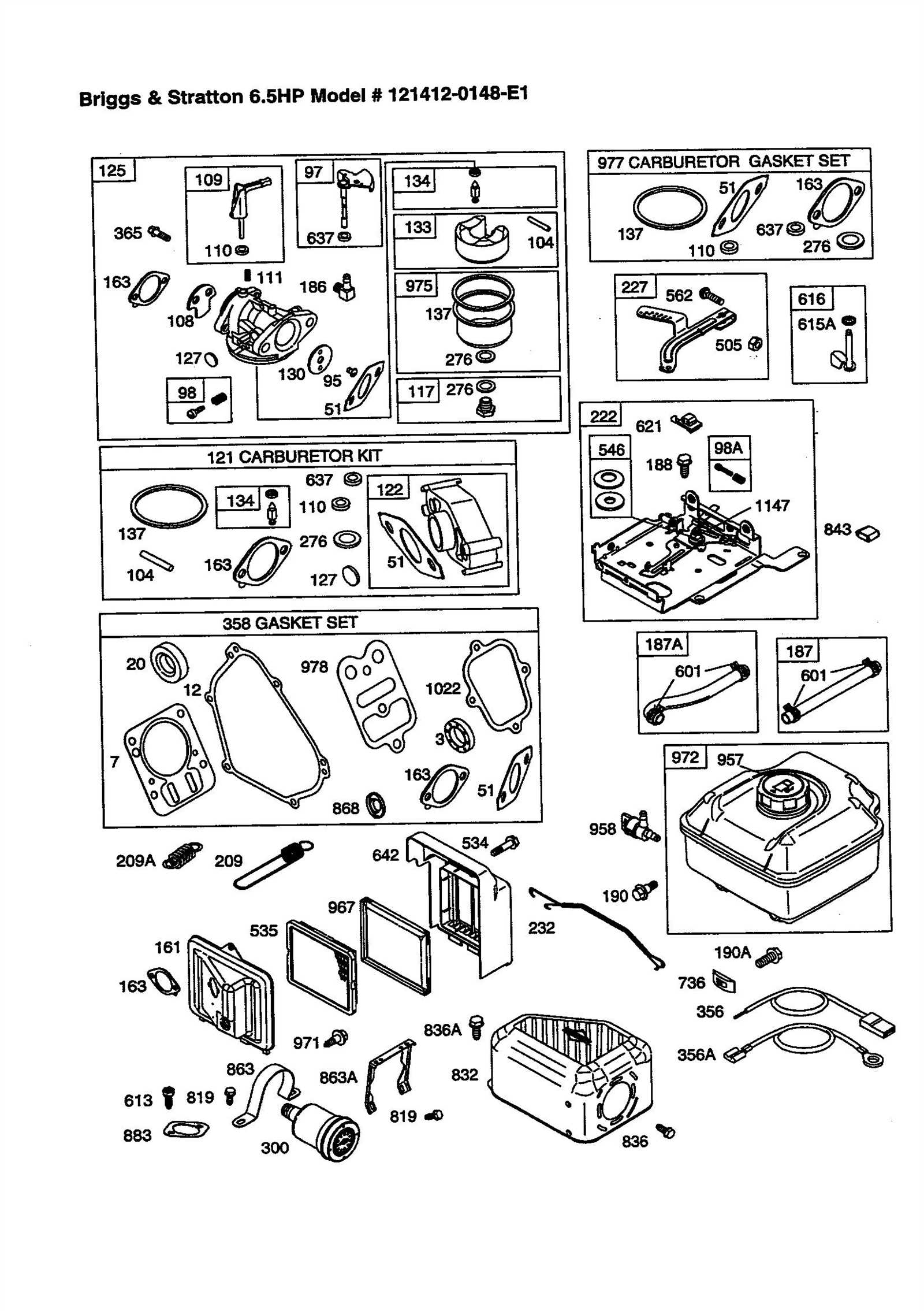

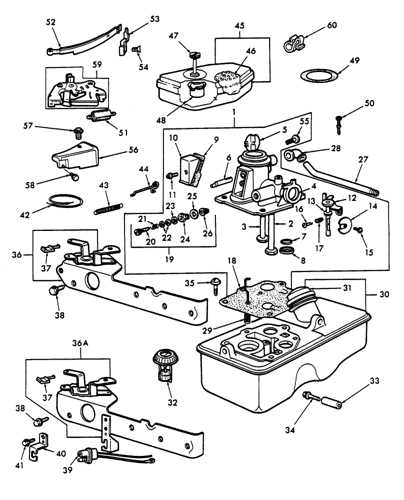

Breaking Down the Visuals

Each section of the image represents a specific area of the engine, showing the positioning of various elements. Look for numbered or labeled parts that correspond to a list of items, which makes identification easy. The layout typically shows a top-down or side view, providing a clear overview of the structure.

Using the Legend and Index

In most illustrations, there will be a legend or an index that explains the numbers or codes used in the diagram. These references help you match the visual components with their actual names or part numbers. Using this system ensures that you can order the correct replacements and maintain the engine effectively.

Replacing Parts on Your Engine

When a component fails or becomes worn, replacing it promptly is essential to maintain the performance and efficiency of your machinery. Understanding the correct procedure for replacing these parts ensures the machine operates as intended, preventing further damage and prolonging its life.

Before starting any replacement, always refer to a detailed visual guide to locate the exact part that needs to be swapped out. Having the right tools and equipment is crucial for removing and installing the new component safely and effectively.

After identifying the damaged element, carefully follow the manufacturer’s instructions for installation. Proper torque settings and alignment are important to avoid improper function. Regularly checking and replacing worn-out parts keeps the engine in optimal condition, allowing for smoother operation and reduced risk of breakdowns.