Maintaining small engines requires a thorough understanding of their internal components. Whether for repair, replacement, or general upkeep, having a clear view of how each part interacts is essential for efficient operation. This section will guide you through the essential elements that make up a typical 18 HP engine, helping you identify key components and their functions.

Proper maintenance ensures that all engine parts are functioning correctly, which can prevent unnecessary breakdowns and extend the life of your equipment. Knowing where each part fits within the engine’s design is crucial for performing repairs or upgrades with confidence. We’ll explore the structure and layout of these critical engine components, offering you a step-by-step approach to understanding their roles.

Understanding the 18 HP V-Twin Engine

The 18 HP engine is a powerful and reliable unit used in a variety of outdoor equipment. Its design allows for optimal performance, providing sufficient power for demanding tasks. Understanding its structure and how the engine functions will help you maintain it properly and troubleshoot any issues that may arise.

This engine features a twin-cylinder configuration, which helps reduce vibrations and ensures smoother operation compared to single-cylinder models. Each cylinder operates in tandem, contributing to increased efficiency and power output. The layout is engineered to deliver long-lasting durability while keeping maintenance requirements manageable.

Familiarity with the different components that make up the engine is crucial for effective repairs. Whether it’s the ignition system, cooling mechanism, or fuel delivery, knowing the role of each part helps you identify potential problems early. With proper knowledge, you can ensure that your engine continues to perform at its best, even under heavy use.

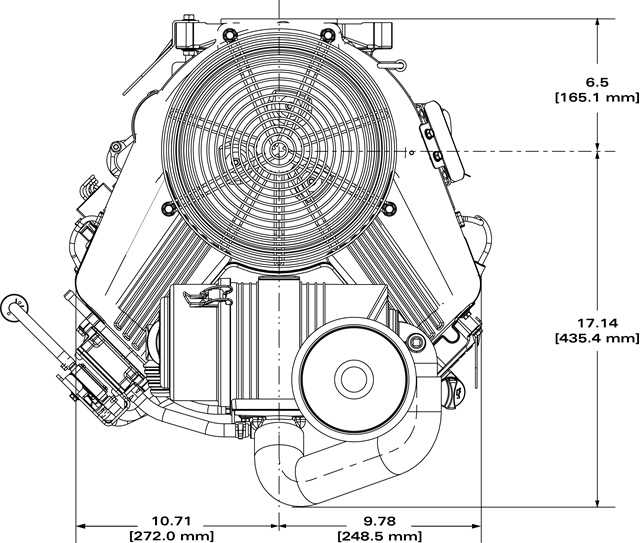

How to Read the Parts Diagram

Understanding how to read the schematic of an engine is essential for identifying the correct components and their placements. This visual reference is designed to help users quickly locate each piece within the assembly and understand how they fit together. By following a few simple steps, you can efficiently navigate through these schematics and ensure you’re selecting the right items for repair or replacement.

Key Elements to Identify

The first step in interpreting a schematic is knowing the basic components that will be shown. These are typically broken down into the following categories:

- Engine Block – The central housing where key internal components like pistons and crankshafts are located.

- Cooling System – Includes parts like the fan and radiator for temperature regulation.

- Fuel System – Components responsible for the delivery and regulation of fuel.

- Ignition System – Parts like the spark plugs and ignition coil that control the engine’s firing mechanism.

Reading the Numbers and Labels

Next, pay attention to the numbers and labels next to each component. These usually correspond to the specific part number or description, making it easier to identify them when ordering replacements. Often, these schematics will also include arrows to show how components interact or fit together. Understanding these markers will ensure that each piece is in the correct position during reassembly.

Common Repairs for 18 HP Engines

Like any engine, the 18 HP unit requires periodic maintenance and occasional repairs to ensure it runs smoothly. Over time, certain parts may wear out or become damaged due to regular use. Understanding the most common issues and how to address them can save time and money, preventing more serious breakdowns down the road.

Some of the most frequent repairs involve the fuel system, ignition components, and cooling mechanism. These areas are critical to the engine’s performance, and addressing problems early can prevent complete failure. Below are some of the typical repairs you might encounter.

- Fuel System Cleaning: Over time, fuel lines and carburetors can become clogged with dirt and debris, leading to poor engine performance. Cleaning or replacing the fuel filter and ensuring the carburetor is free of blockages can resolve many fuel-related issues.

- Spark Plug Replacement: Worn-out spark plugs can cause misfires, difficulty starting, or reduced power output. Replacing them regularly ensures smooth ignition and optimal engine performance.

- Cooling Fan Repair: The cooling system, including the fan, may become obstructed by debris or suffer from wear and tear. Clearing any blockages and checking the fan for damage can prevent overheating and engine failure.

- Oil Change and Replacement: Regularly changing the engine oil is essential to maintaining lubrication and preventing internal damage. Neglecting this step can lead to increased friction and premature wear on engine components.

By staying on top of these routine repairs, you can extend the lifespan of your engine and ensure it operates at peak efficiency for years to come.