When working with a 15 horsepower outboard motor, it’s essential to have a clear understanding of its structure and key elements. Every component plays a specific role in the overall functioning of the engine, and recognizing their connections can significantly improve maintenance and troubleshooting efforts. Familiarizing yourself with the different sections of the engine ensures efficient repairs and better performance.

Proper maintenance begins with knowing how to identify each individual part, and this knowledge can help you spot potential issues before they become major problems. Whether you’re replacing a worn-out piece or upgrading a function, being able to pinpoint each component is crucial.

With a solid grasp of the engine’s setup, you’ll be able to approach repairs confidently. Recognizing how everything fits together allows for smoother operation and a longer lifespan for the motor. A detailed understanding can also save time and costs by helping you make informed decisions about replacement parts and tools.

Understanding 15 HP Outboard Motor Components

Key Elements in the Engine Assembly

In any outboard engine, the assembly of components is crucial for optimal performance. Each element has a specific function, and their seamless interaction ensures the motor runs efficiently. Familiarizing yourself with these critical parts helps in both regular maintenance and in troubleshooting potential issues that may arise during operation.

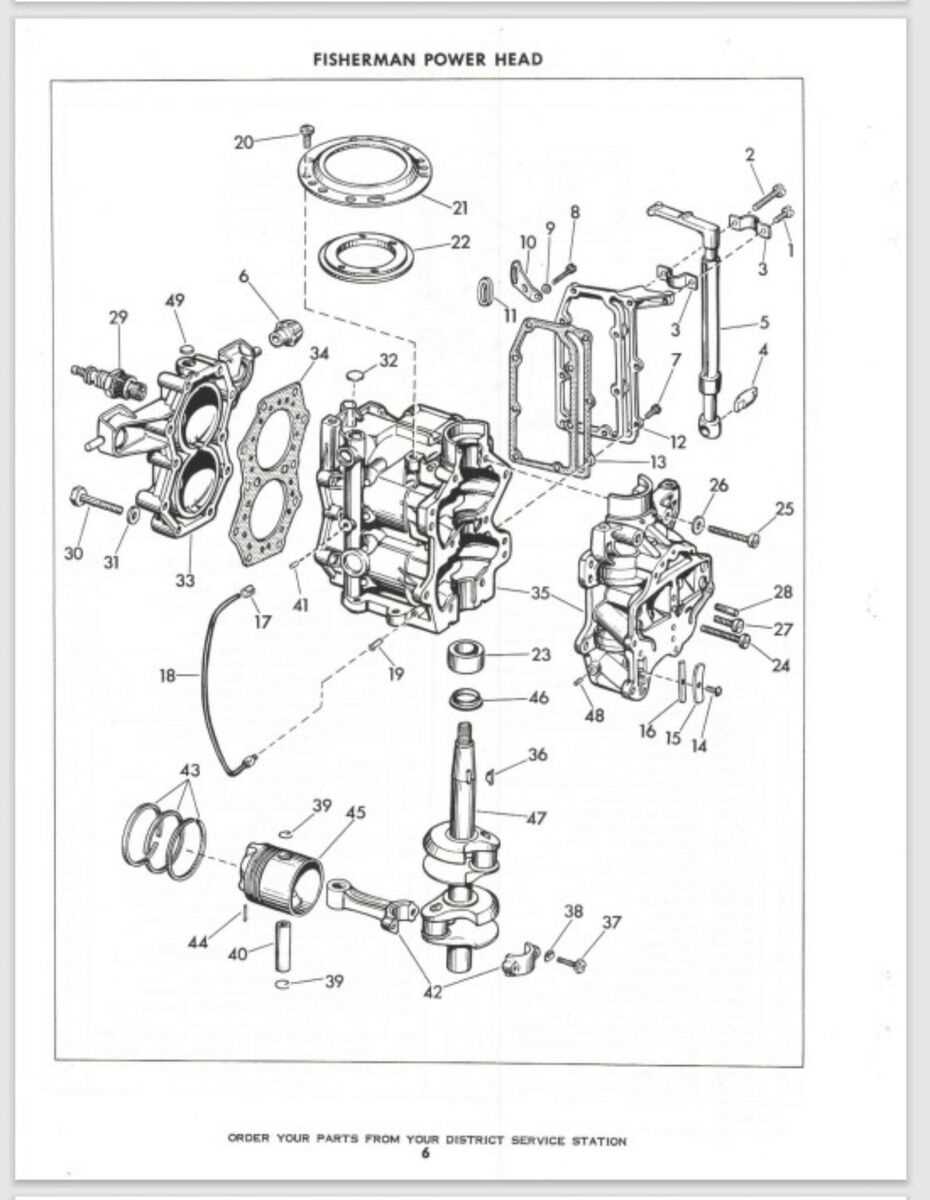

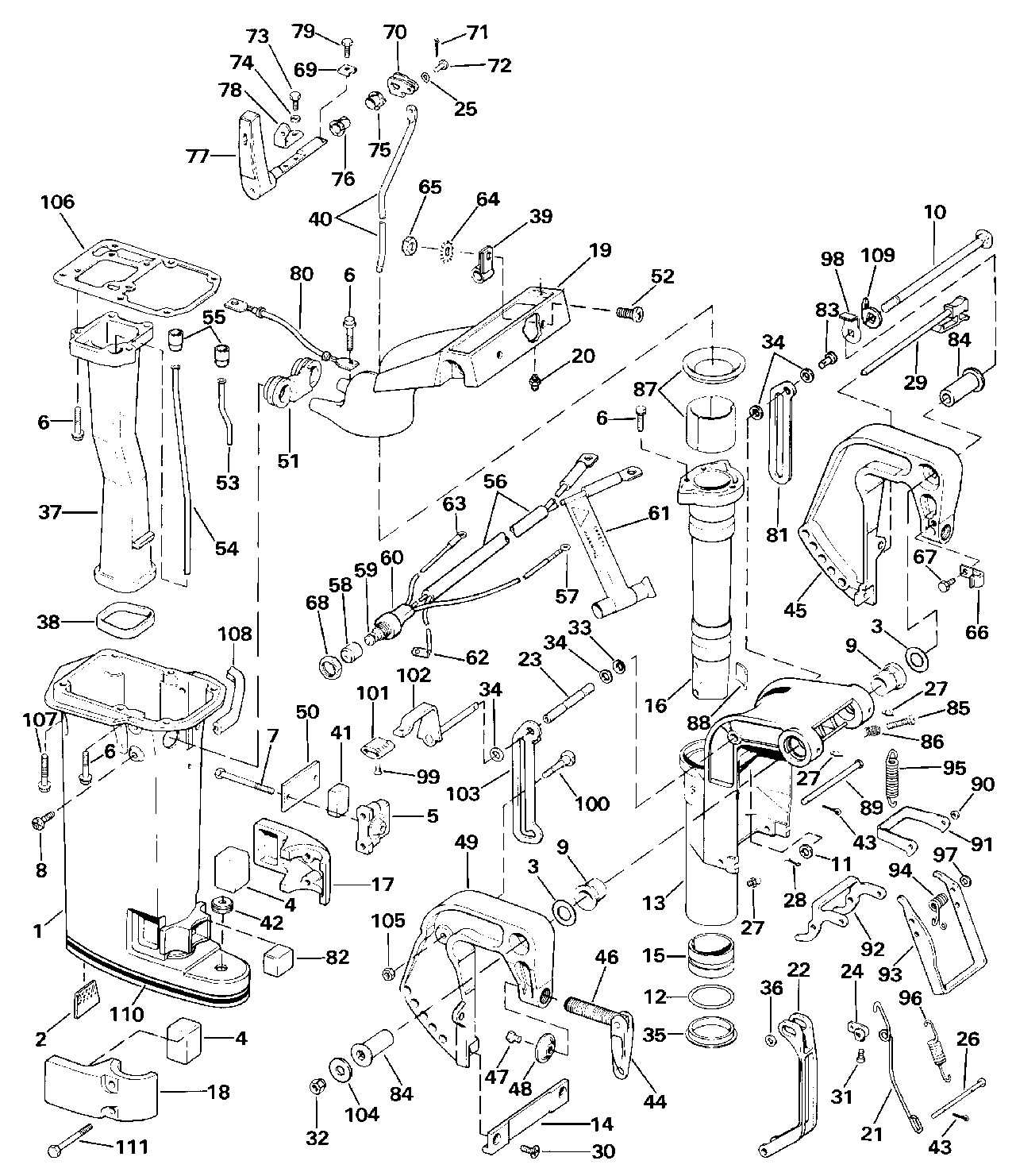

The engine assembly includes a range of key components such as the crankshaft, cylinder head, and fuel system. These parts work together to convert fuel into mechanical energy, propelling the boat forward. Understanding the role of each individual component allows for quicker identification of issues and more efficient repairs.

Additionally, the cooling system, ignition system, and exhaust components are vital for maintaining proper engine temperatures and efficient exhaust flow. These systems ensure the engine runs at peak efficiency while minimizing wear and tear over time. A thorough understanding of these elements is essential for anyone looking to optimize the performance and lifespan of their motor.

How to Read the Engine Assembly Schematic

Identifying Key 15 HP Outboard Motor Elements

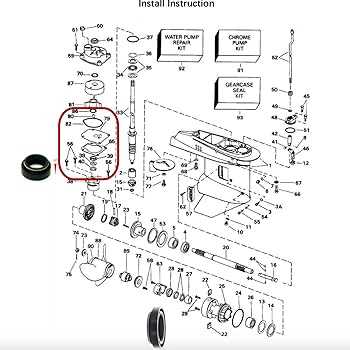

Understanding how to interpret an engine schematic is crucial for anyone performing repairs or maintenance on an outboard motor. The diagram acts as a roadmap, guiding you through the various components and their relationships. By learning to read the layout properly, you can identify which part corresponds to each function and spot potential issues more easily.

Key Features to Look For

In the schematic, each component is typically numbered and labeled. This makes it easier to track down specific parts and understand their position in the assembly. Pay attention to the layout, as it often reflects the order in which components interact during engine operation, such as fuel intake, ignition, and exhaust cycles.

Common Symbols and Terminology

Different components are represented by symbols, and understanding these symbols is key to interpreting the schematic correctly. Lines, arrows, and specific labels can indicate connections, flow direction, or mounting points. Familiarizing yourself with these symbols will ensure you fully understand the engine’s structure and functionality, which is essential when diagnosing or replacing elements.

Common Problems and Solutions for Engine Components

Outboard motors can encounter a variety of issues over time, especially with frequent use. These problems can arise from wear and tear, environmental conditions, or improper maintenance. Recognizing these issues early on and knowing how to address them can help maintain optimal performance and prevent costly repairs in the future.

One common issue is fuel inefficiency, which can be caused by clogged fuel filters or faulty fuel lines. Regularly replacing the filters and inspecting the fuel system can restore proper fuel flow and improve engine performance. Another frequent problem is overheating, often due to a malfunctioning cooling system. Checking the water pump and cooling passages regularly can prevent this from becoming a significant issue.

Electrical problems, such as a weak spark or no ignition, are also typical. These can often be traced back to faulty ignition components, such as the spark plugs or coils. Replacing damaged or worn-out components will typically resolve these issues. Regular maintenance and proper storage can reduce the frequency of these problems and ensure the engine runs smoothly throughout its lifespan.