When maintaining outdoor power tools, it’s essential to have a clear understanding of their structure and how each part interacts. Knowing how to identify and replace specific elements can significantly extend the life of your machine and improve its performance. Having a clear overview of these components allows users to perform repairs efficiently and with confidence.

Proper maintenance starts with being able to visualize and locate key elements that need attention. Whether you’re performing routine checks or tackling a more complex issue, a detailed overview of the tool’s system is invaluable. This guide will walk you through essential components and provide helpful insights for maintenance tasks.

Regular care of your machine ensures it remains in top working condition for longer periods. Familiarizing yourself with the internal structure helps in identifying potential problems before they worsen. With a little knowledge and the right resources, you can easily address common issues and keep your equipment performing at its best.

Understanding the Husqvarna 128cd Parts

Every outdoor tool is made up of various components, each playing a critical role in its overall functionality. To ensure optimal performance and prevent unnecessary wear, it’s crucial to understand how these different elements work together. Familiarity with your tool’s internal structure allows for easier diagnosis of issues and more effective maintenance.

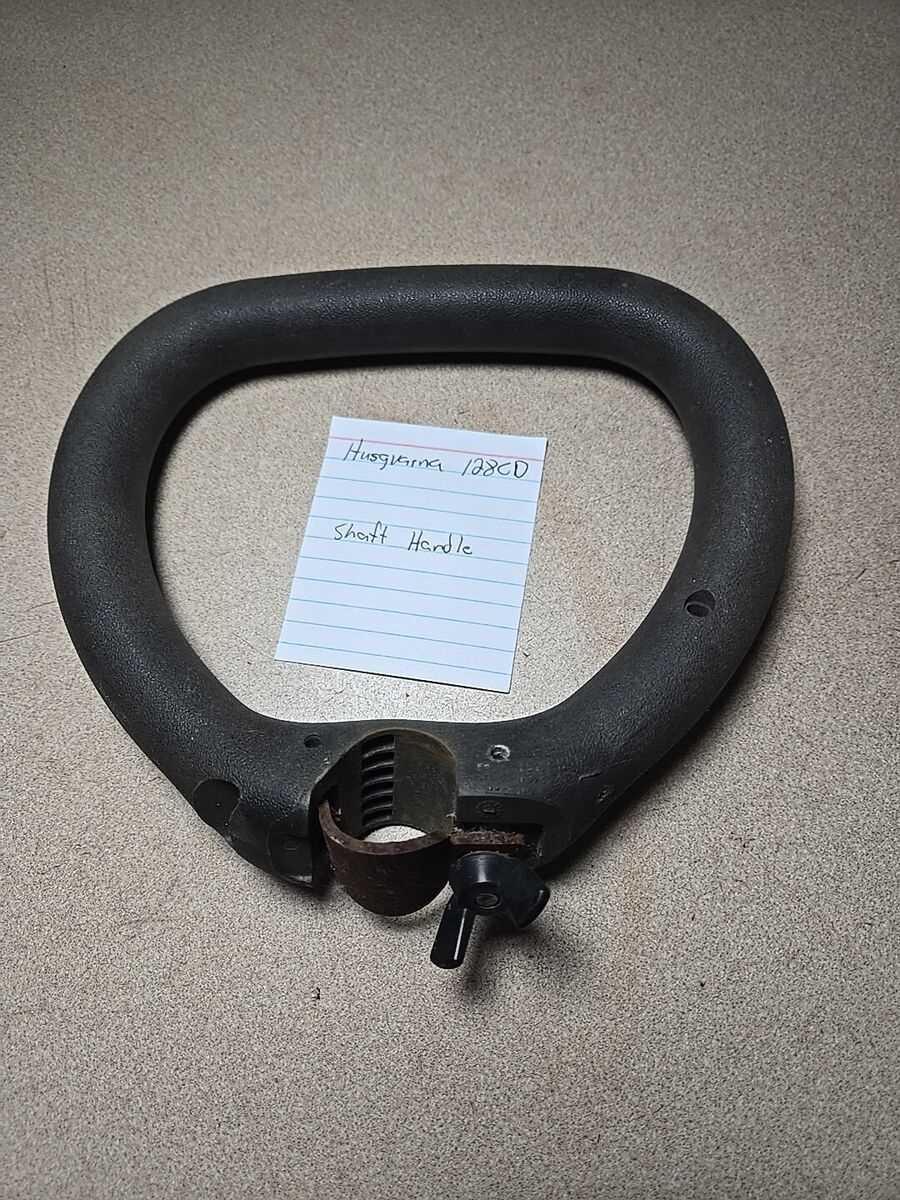

The key components are often the engine, fuel system, cutting mechanism, and various support structures that keep everything in place. These elements require regular inspection to ensure they’re in good working condition. Knowing how to identify and access each part makes troubleshooting simpler and faster, especially when repairs are necessary.

Routine maintenance is vital for ensuring that each part functions smoothly over time. Identifying the signs of wear early on can help prevent costly damage. Whether it’s a worn-out clutch or a damaged air filter, timely intervention can maintain the tool’s efficiency and extend its service life.

How to Read the Husqvarna Parts Diagram

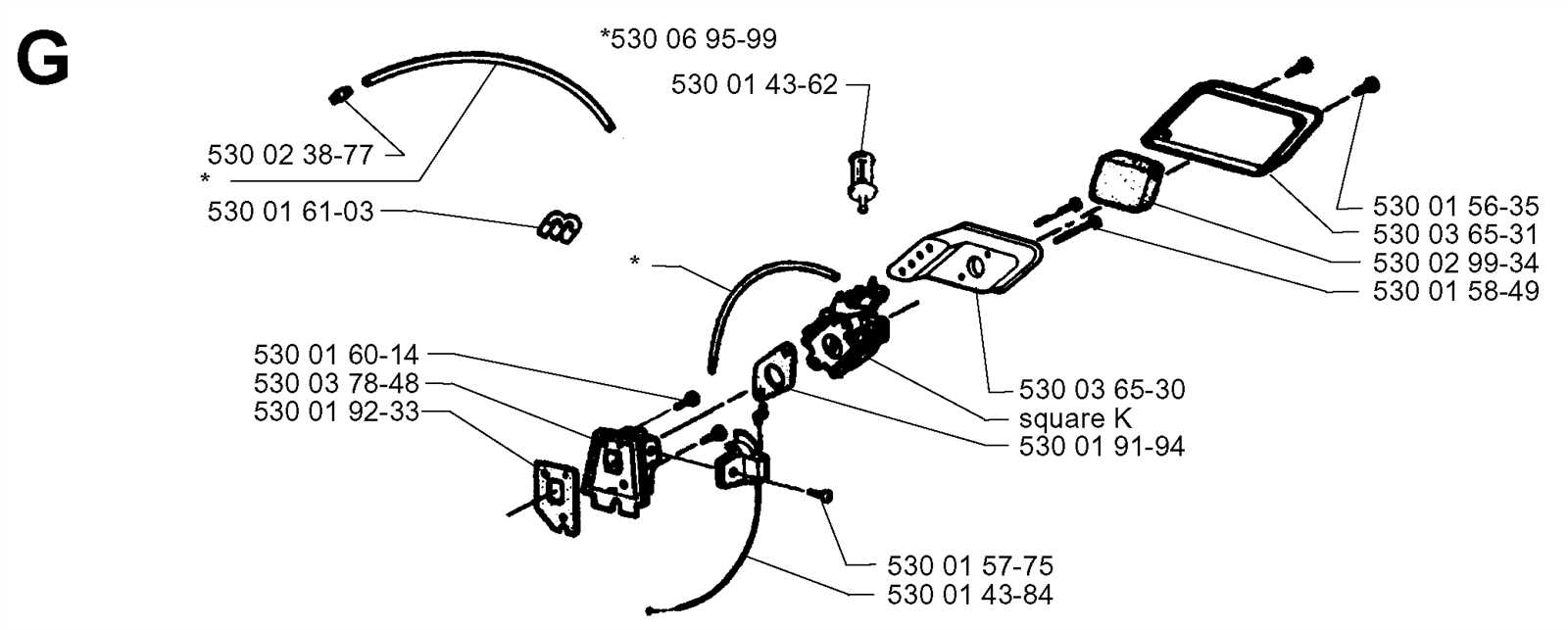

Understanding how to interpret visual representations of your equipment’s components is essential for effective maintenance. These illustrations provide a detailed overview of each element’s placement, function, and how they all connect. Knowing how to read these guides can significantly simplify repair and replacement processes.

Familiarize Yourself with Key Sections

The first step in reading these guides is to identify the key sections and components. Typically, these illustrations are divided into groups, such as the engine assembly, fuel system, and cutting elements. Each section is numbered or labeled for easy reference, allowing you to quickly locate the part you need to inspect or replace.

Identifying Part Numbers and Descriptions

In most guides, each part is marked with a specific identification number and brief description. This makes it easier to cross-reference with the tool’s manual or replacement catalog. When looking for a part to replace, you can use these numbers to ensure compatibility and get the correct item, saving time and avoiding mistakes.

Detailed attention to these diagrams can reveal potential issues, such as misalignments or damaged components, that may not be obvious through visual inspection alone. Once you’re comfortable with reading these guides, you’ll be able to perform basic troubleshooting and make informed decisions about which parts need attention.

Essential Parts for Husqvarna 128cd Maintenance

Proper maintenance of outdoor power tools requires attention to several critical components that directly impact performance. These key elements are responsible for ensuring smooth operation, preventing breakdowns, and extending the overall lifespan of the equipment. Regular checks and timely replacements are vital to keep everything functioning as it should.

The engine assembly is one of the most important parts to monitor, as it powers the tool. Maintaining a clean air filter and ensuring the fuel system is free of debris is essential for the engine to run efficiently. Additionally, the cutting mechanism, including the blades and associated gears, should be inspected regularly for wear and tear, ensuring sharpness and proper alignment.

Lubrication is another crucial aspect that should not be overlooked. Components such as bearings and other moving parts require regular lubrication to reduce friction and prevent overheating. Also, the clutch mechanism plays a major role in transferring power, so keeping it in good condition is important for smooth operation during use.

By keeping these essential elements in check, users can avoid costly repairs and maintain the tool’s performance over the long term. Understanding these critical components will enable you to perform effective routine maintenance and address potential issues before they escalate.