Understanding the internal structure of your chainsaw is crucial for efficient maintenance and repairs. A comprehensive breakdown of each component can help you identify issues faster and ensure the longevity of your equipment. Whether you are a seasoned professional or a DIY enthusiast, having a clear visual guide is essential for performing accurate fixes.

With proper knowledge of the different parts, you can easily diagnose problems and replace faulty components without unnecessary hassle. This guide provides a structured approach to help you navigate through the essential elements of your chainsaw, giving you the confidence to handle any repair job.

By familiarizing yourself with the key sections of the machine, you’ll be able to perform regular upkeep, extend the life of your chainsaw, and avoid costly repairs. With a step-by-step understanding of its design, you can take better care of your tool and keep it running smoothly for years to come.

Understanding the Chainsaw Components

Knowing the different elements of your chainsaw and how they work together is vital for proper maintenance and troubleshooting. Each component plays a specific role in the overall operation, and understanding these roles helps ensure that your tool operates efficiently. Familiarity with these parts also enables you to pinpoint potential issues more quickly and address them effectively.

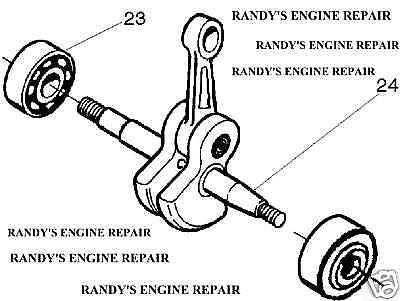

The chainsaw is composed of several key sections, each responsible for a different aspect of performance. The engine, cutting mechanisms, safety features, and control systems must all be in good working order for the machine to function properly. Identifying the location and function of each part can assist in troubleshooting and repair, making the process simpler and more accurate.

Once you gain a deeper understanding of the components and their interactions, performing regular maintenance tasks, such as oiling or replacing worn-out parts, becomes much easier. By recognizing the signs of damage or wear in specific sections, you can extend the life of your chainsaw and keep it running smoothly.

How to Use the Components Breakdown Effectively

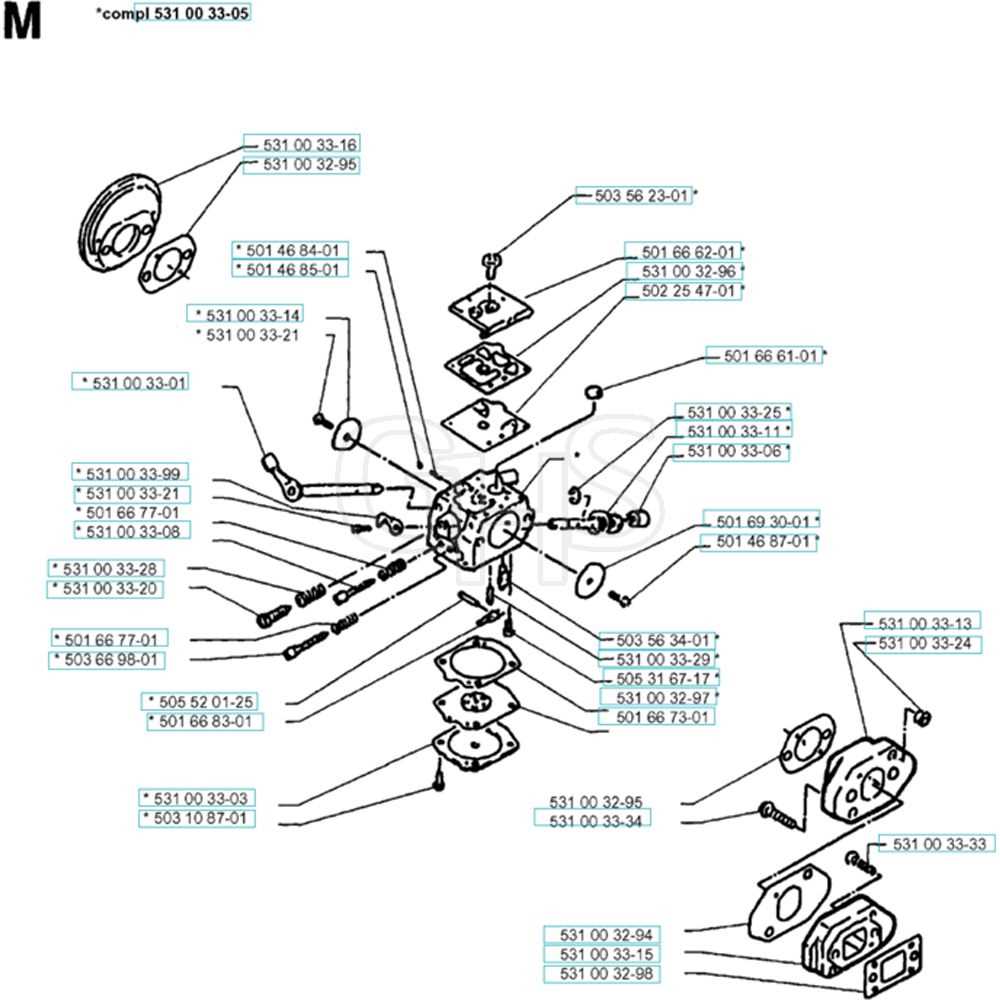

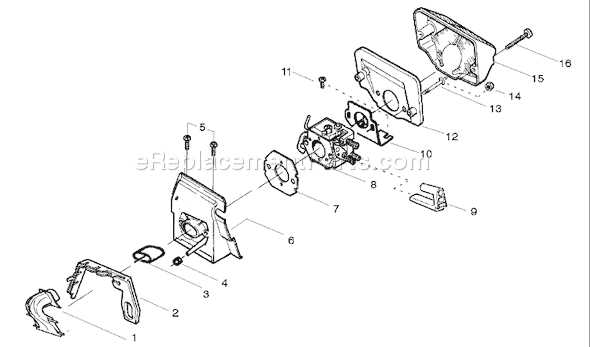

To maximize the effectiveness of your tool repair process, understanding how to interpret a detailed visual reference is essential. A clear illustration that shows the layout and arrangement of each part can save you time and effort by guiding you directly to the components that need attention. By using this guide properly, you can pinpoint specific areas for repair or replacement with confidence.

Familiarize Yourself with the Layout

Before diving into any repairs, take time to study the layout carefully. Pay attention to how each section is represented and how the components are numbered or grouped. This will help you understand the machine’s structure and identify which parts work together, making troubleshooting much easier.

Follow a Step-by-Step Approach

When addressing issues, always use the reference step by step. Start with the general overview of the system, and then focus on the specific area of concern. Cross-reference the diagram with the actual tool to confirm the correct placement of parts, ensuring that you are replacing or repairing the right component.

By following this method, you reduce the risk of errors and ensure that your machine is repaired or maintained correctly, enhancing its performance and longevity.

Common Repairs for Chainsaw

Over time, even the most durable chainsaws can experience issues that require repair. Whether it’s due to regular wear and tear or occasional mishandling, certain components are more likely to need attention. Knowing the most common repairs helps you prepare and act quickly when problems arise, ensuring your tool remains functional for longer periods.

One of the most frequent repairs involves the cutting chain. If it becomes dull or damaged, it will significantly affect performance. Regular sharpening or replacing the chain entirely can improve cutting efficiency and reduce strain on the engine.

Another common issue is with the spark plug, which can wear out over time, causing engine misfires or difficulty starting. Replacing the spark plug is an easy and cost-effective fix that can restore proper ignition and engine operation.

The fuel system is also a frequent source of problems. If the fuel lines become clogged or damaged, it can prevent the engine from receiving the necessary fuel, leading to performance issues. Inspecting and replacing the fuel lines, filters, or carburetor components can resolve these types of issues.