Maintaining outdoor power equipment requires a deep understanding of its individual components and their functions. With the right resources, identifying each part and knowing how they work together can simplify the repair process and extend the life of your equipment.

Whether you’re looking to replace a worn-out component or troubleshoot a malfunction, having a clear view of the equipment’s structure is key. This guide provides valuable insights into the main components, their interactions, and how to manage common issues.

Proper maintenance ensures that your machine operates efficiently. By familiarizing yourself with each element and its purpose, you can approach repairs confidently, minimizing downtime and maximizing performance.

Essential Components of Husqvarna 329L

Every piece of outdoor equipment relies on a carefully designed system of interworking elements. Understanding these components is crucial for effective maintenance and repair, ensuring smooth operation and longevity.

The engine, for example, is the heart of the machine, converting energy into mechanical motion. Equally important, the ignition system sparks the engine to life, allowing it to run efficiently. Other key elements such as the fuel delivery system and air filter also play vital roles in the performance of the equipment, affecting everything from power output to fuel efficiency.

Safety and performance rely heavily on the integrity of each component. Regular inspection and proper upkeep can help you identify signs of wear and prevent potential issues before they arise. By focusing on the most essential elements, you can maintain peak performance and avoid unnecessary repairs.

How to Interpret the Parts Diagram

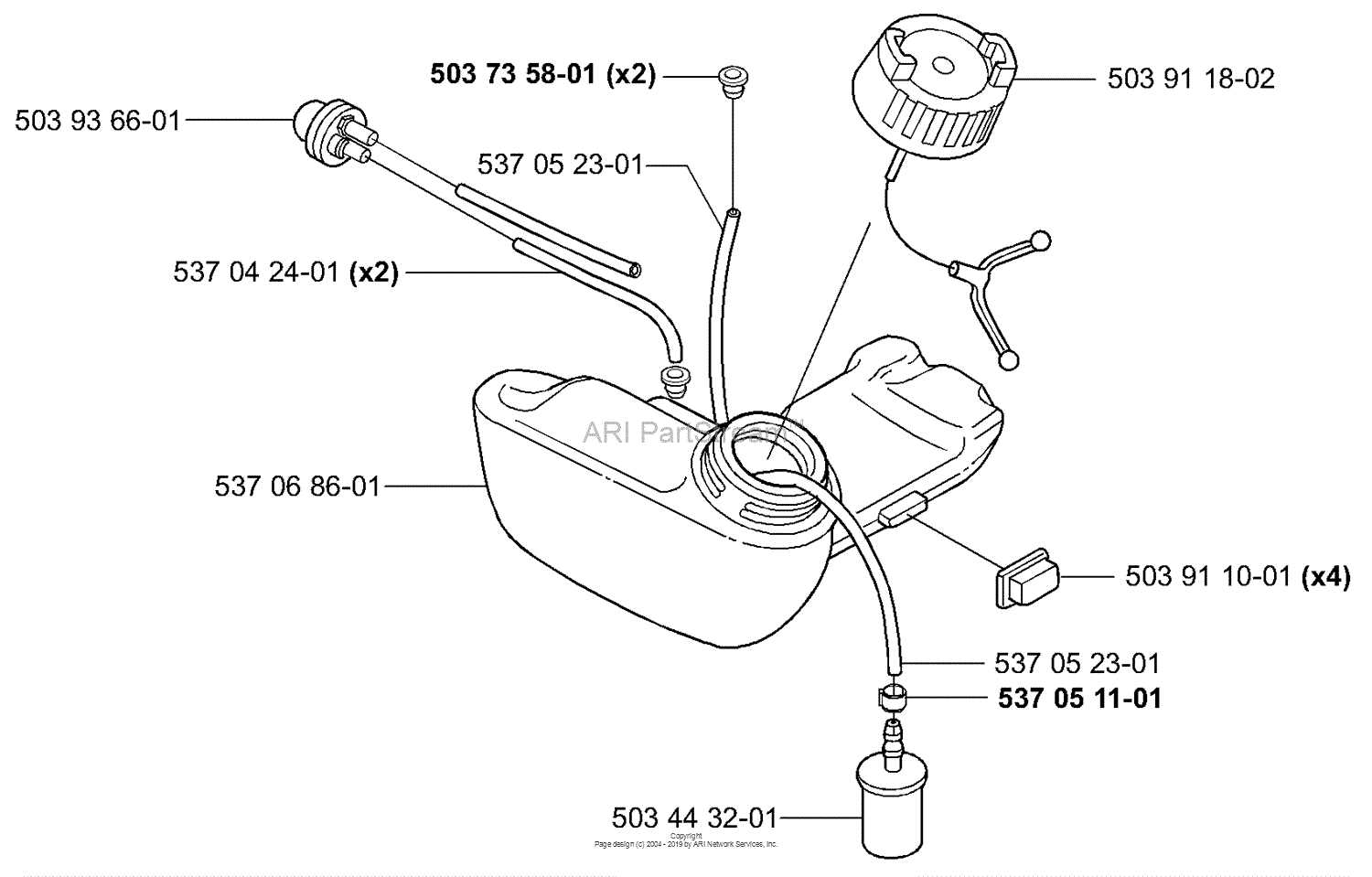

Understanding the layout of individual components and their connections is essential for efficient troubleshooting and repair. A well-organized visual representation of your machine can help you quickly identify parts, making the process of replacement or maintenance more manageable.

Recognizing Key Elements

Start by identifying major sections, such as the engine, fuel system, and control mechanisms. These areas usually have distinct markers or labels that highlight their function within the entire system. Focus on these components first, as they typically influence the overall performance of the machine.

Following the Connections

Next, examine how parts are connected. Arrows and lines often indicate movement or flow, helping you understand how energy, air, or fuel circulates through the machine. By following these connections, you can spot potential issues or identify which components might need attention based on their function.

Common Repairs Using the Parts Diagram

Routine maintenance and timely repairs are key to keeping equipment running smoothly. By referring to a clear visual guide, identifying worn or faulty components becomes easier, allowing for more effective repairs and longer equipment life.

Replacing the Fuel System Components

One of the most common repairs involves the fuel system, including the fuel lines, filter, and carburetor. Over time, these parts can clog or degrade, leading to poor performance or starting issues. The diagram will help you locate these elements and replace them efficiently to restore fuel flow and ensure proper engine function.

Fixing the Ignition System

If the engine fails to start or runs erratically, the ignition system might be at fault. Worn spark plugs or damaged wires can cause misfires. By identifying the relevant components on the schematic, you can replace faulty parts and quickly troubleshoot any issues with the spark generation process.