When maintaining or repairing any high-performance chainsaw, understanding the intricate structure of its individual parts is crucial. A visual breakdown of these components not only aids in identifying each piece but also enhances your ability to troubleshoot and replace faulty elements with ease. This approach ensures that all pieces fit together perfectly, optimizing the overall functionality of the tool.

By referring to detailed illustrations, you can gain a deeper insight into how each part interacts with others, helping to prevent errors during assembly or repair. Knowing where specific components are located allows for quicker and more accurate fixes, ensuring your equipment remains in top condition for extended use. Proper maintenance becomes much easier once you are familiar with each element’s role.

Whether you’re an experienced technician or a DIY enthusiast, this guide will provide you with the essential information to navigate the complex setup of your equipment. Through a clear understanding of its makeup, you can maximize its lifespan and performance with minimal effort.

Understanding Chainsaw Components

Every chainsaw consists of numerous essential elements that work together to provide efficient performance. From the engine to the cutting mechanism, each component plays a crucial role in ensuring smooth operation. Gaining a clear understanding of these parts helps with proper maintenance, troubleshooting, and replacement, allowing users to keep their equipment running at peak efficiency.

The power unit, consisting of various mechanical and electrical components, is the heart of the tool. Its interaction with the fuel system, ignition system, and exhaust components determines how well the engine runs. Equally important are the transmission and guide bar, which directly impact the chainsaw’s cutting power and ease of use.

Familiarity with each individual component’s function allows for more effective diagnostics and repair. Understanding how to identify a worn-out or malfunctioning part will save time and effort, reducing downtime and increasing the lifespan of the chainsaw.

Key Parts of the Chainsaw

To fully understand how a chainsaw functions, it’s important to recognize the crucial components that make up its overall system. From the power source to the cutting elements, each part contributes to the tool’s performance and reliability. Understanding these key elements can help with efficient maintenance and repair, ensuring the chainsaw operates smoothly for a long time.

Engine and Power System

The engine is the core of any chainsaw, providing the necessary power for operation. It is made up of the fuel system, ignition system, and various internal components that work together to generate energy. The efficiency of the engine directly influences the tool’s cutting power and runtime, making regular maintenance of these components essential for optimal performance.

Cutting Mechanism

The cutting system, which includes the guide bar, chain, and sprocket, is responsible for the chainsaw’s ability to cut through wood efficiently. The guide bar keeps the chain in place, while the sprocket drives the chain’s movement. A well-maintained cutting mechanism ensures smooth operation and effective cutting, preventing wear and tear on both the chain and bar.

How to Use the Visual Breakdown Effectively

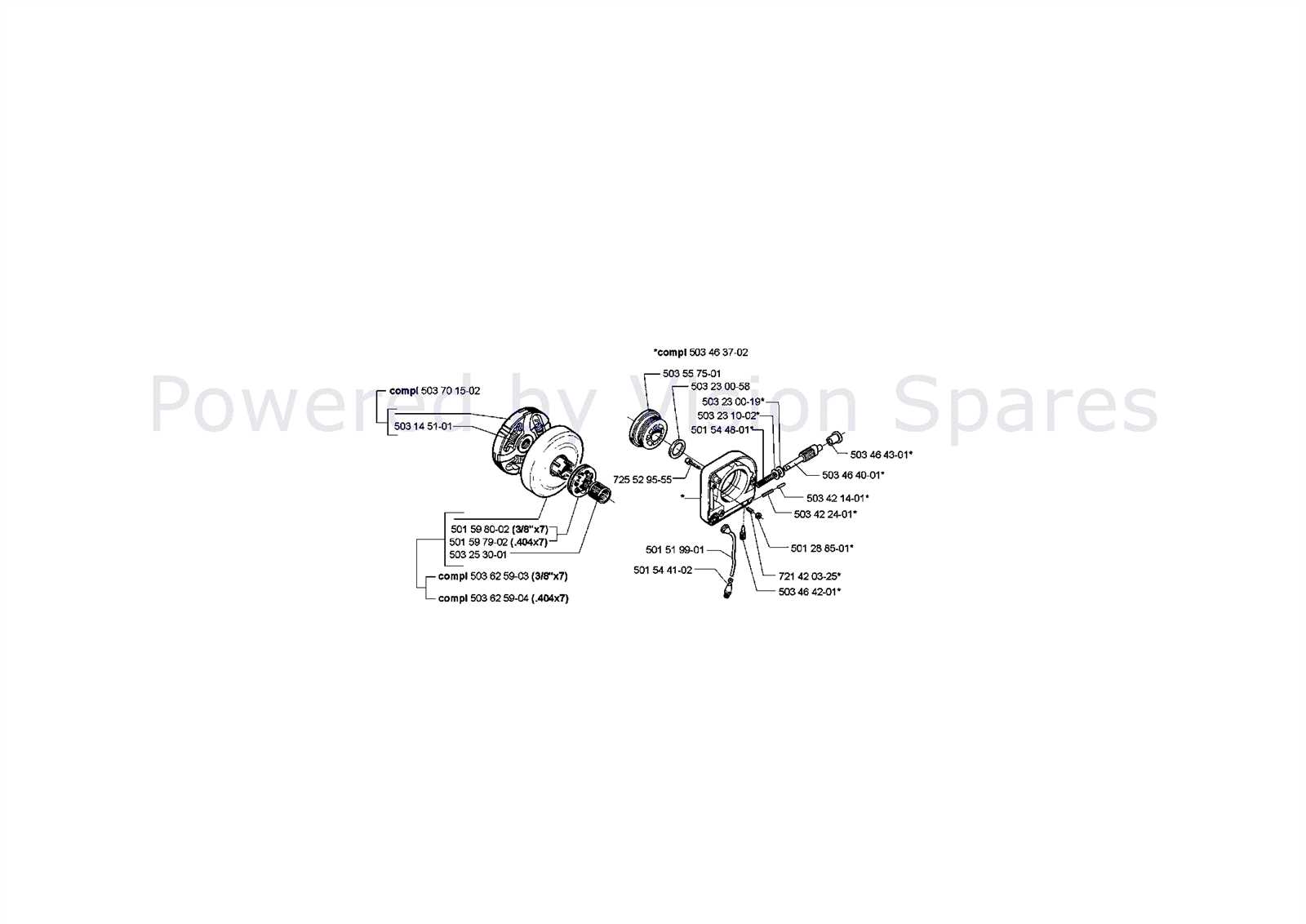

A detailed visual representation of your chainsaw’s internal components can be an invaluable tool when it comes to repairs or maintenance. Understanding how to read and use these illustrations allows you to identify the exact location of each part, helping you spot potential issues or plan a replacement efficiently. Proper use of such references not only saves time but ensures accurate assembly or disassembly.

Start by familiarizing yourself with the layout and labeling of the visual guide. Focus on identifying major sections like the engine, cutting mechanism, and fuel system. Proper attention to the arrangement of parts will help you locate any worn or damaged elements quickly. Additionally, these diagrams often include part numbers, which are essential for sourcing replacements.

When performing maintenance, use the visual breakdown as a checklist. Compare each component with the guide to confirm its condition and positioning. This method ensures that no part is overlooked and helps avoid common mistakes, improving the overall effectiveness of your repair work.