Understanding the internal structure of your cutting tool is crucial for its long-term performance and reliability. Knowing how different elements work together can help with both routine maintenance and troubleshooting. This guide will help you identify the key components that make up a typical chainsaw.

Each machine is made up of a variety of parts, each playing a specific role. From the engine to the cutting mechanism, it’s essential to recognize how these elements interact to ensure smooth operation. Proper knowledge of these parts can also assist in identifying potential issues before they affect the performance.

Familiarity with the assembly allows for more effective repairs and replacements when needed. Understanding the arrangement and functions of each part can make servicing simpler, saving you both time and money in the long run.

Understanding the Chainsaw Components

Every cutting tool consists of multiple interconnected elements that work together to deliver high performance. Understanding these components and how they function is essential for proper maintenance and smooth operation. The key to effective upkeep lies in recognizing each individual part’s role and how they contribute to the overall system.

Main Engine and Power System

The power system is the heart of the machine, consisting of the engine and associated components that drive the cutting mechanism. This system includes critical elements such as the fuel tank, ignition system, and exhaust. Efficient engine function is crucial for optimal performance, as even the smallest malfunction can affect cutting power and efficiency.

Cutting and Safety Mechanisms

The cutting mechanism includes the chain, bar, and related components that engage with the material being cut. These parts are designed for durability and precision. Regular inspection of these components ensures that the chainsaw remains effective and safe to operate. Any damage or wear in the cutting system should be addressed promptly to maintain both performance and safety.

How to Read the Assembly Breakdown

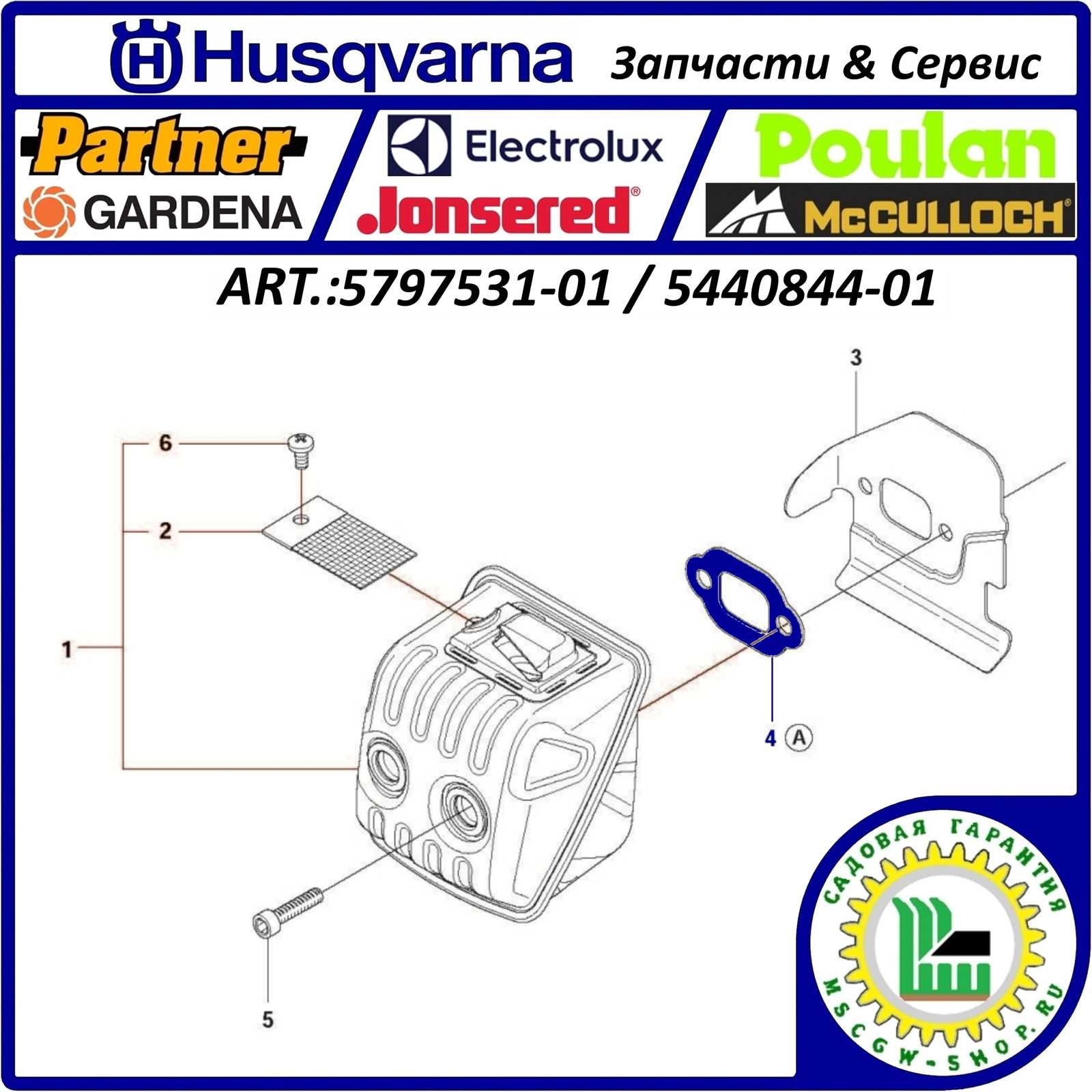

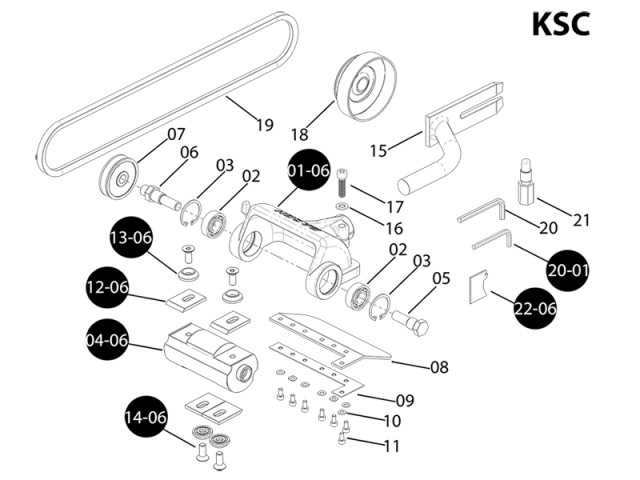

Interpreting an assembly breakdown can initially seem complex, but with the right approach, it becomes an invaluable tool for identifying individual components. These visual guides offer detailed views of the machine’s structure, making it easier to pinpoint specific parts and their functions. Understanding how to read these illustrations will simplify maintenance and repair tasks.

Each section of the breakdown typically highlights a group of components that work together. By following the layout, you can trace each element’s position and how it connects to the larger system. The labels and part numbers included in these guides allow for quick identification and provide valuable insight when ordering replacements or performing repairs.

Essential Components for Chainsaw Maintenance

Maintaining your cutting tool requires regular attention to several key elements. These components play crucial roles in ensuring the machine operates smoothly and effectively. Keeping these parts in top condition not only extends the lifespan of the tool but also ensures its reliability during use.

Engine and Fuel System

The engine and fuel system are at the core of the machine’s performance. Proper maintenance of the spark plug, fuel lines, and filter can prevent power loss and ensure consistent operation. Regularly checking the fuel mixture and inspecting the fuel system for leaks or blockages is essential for optimal engine performance.

Cutting Mechanism and Safety Features

The cutting chain and guide bar must be inspected frequently to ensure they are not worn down or damaged. Keeping the chain properly tensioned and lubricated is vital for safe and efficient operation. Additionally, checking safety features such as the chain brake and handle ensures the machine remains safe to operate at all times.