When maintaining or repairing your tool, it’s essential to have a clear understanding of its internal structure. Identifying each individual component can save time and effort, especially when troubleshooting or replacing parts. A detailed layout helps you visualize how everything works together, ensuring a smoother repair process.

Knowing the specific pieces of your chainsaw allows for a more efficient approach to maintenance. By referencing a detailed map of its structure, you can pinpoint issues more quickly and confidently. Whether you’re replacing worn-out elements or performing general upkeep, understanding the configuration is vital for success.

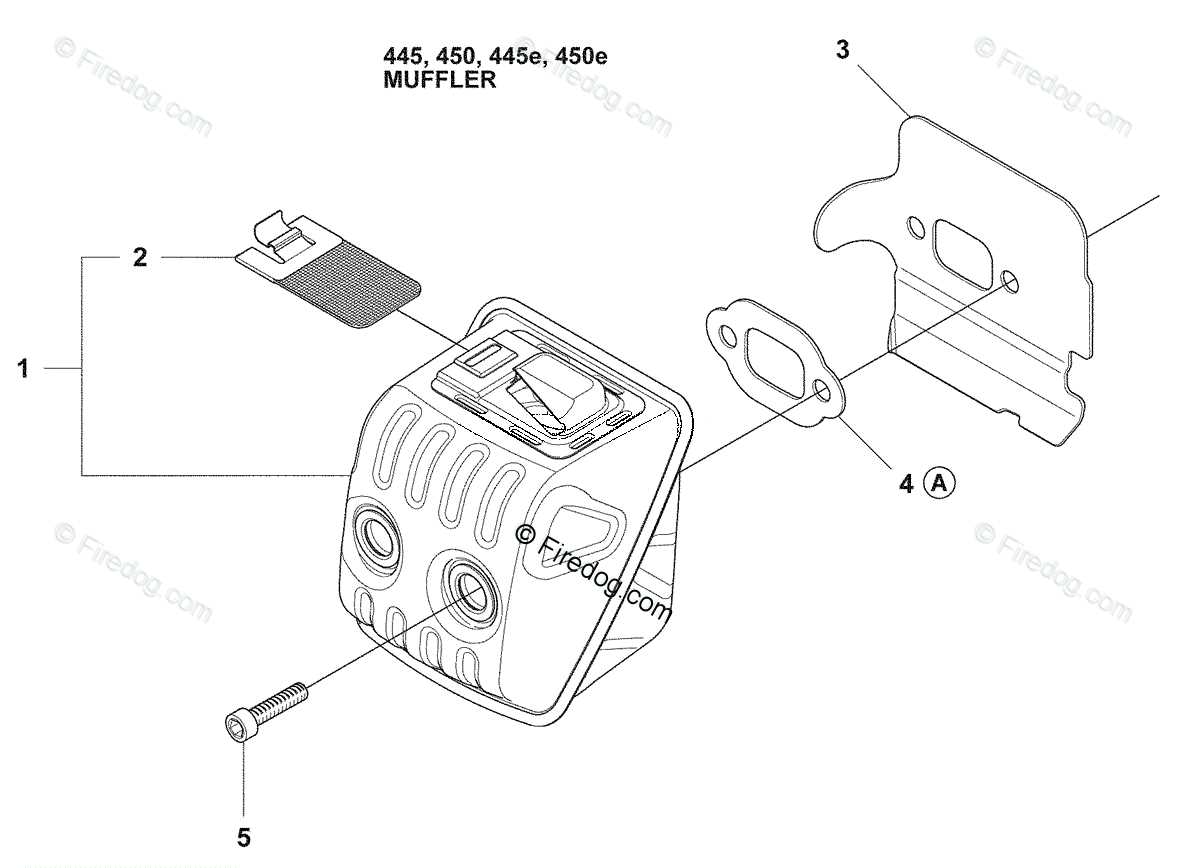

Efficient repairs depend on having access to comprehensive guides and clear visuals. This resource offers a closer look at the tool’s intricate system, helping you avoid mistakes and improve the overall lifespan of your equipment.

Understanding the Husqvarna 445 Parts Layout

Knowing the internal arrangement of your tool is essential for maintaining its efficiency. A clear view of how each component fits into the overall structure can help in identifying potential issues and understanding the role of every piece. This knowledge makes repair and maintenance processes much smoother, reducing the likelihood of mistakes or missed steps.

The Key Sections of Your Tool

Each tool is divided into key areas that contribute to its overall function. These sections include the engine, the power system, and the safety features. By familiarizing yourself with these parts, you can quickly assess the condition of your equipment and address any issues promptly.

- Engine components: These parts are essential for the tool’s performance and require regular inspection for optimal functionality.

- Power system: This includes the fuel and air intake systems, which need to be kept clean for smooth operation.

- Safety features: Critical for preventing accidents, these parts should always be in good working condition.

How to Use the Layout for Maintenance

A detailed breakdown not only helps identify parts but also guides you through common repair tasks. Whether you are replacing a worn-out element or adjusting a loose connection, understanding where each component is located makes the job faster and easier.

- Locate the component needing repair or replacement.

- Use the layout to identify all related parts that may need attention.

- Follow the correct procedure for dismantling and reassembling.

- Ensure all parts are secure and functioning before use.

How to Identify Husqvarna 445 Components

Identifying the individual components of your equipment is crucial for proper maintenance and repair. Understanding each piece’s function allows you to address issues more effectively and ensures that the tool performs at its best. The process involves carefully examining the structure and matching each part with its corresponding function.

Visual Identification Tips

One of the first steps in identifying components is recognizing their visual characteristics. Many pieces are designed with distinct features that help in their identification. For example, engine parts often have a robust structure, while safety features are typically more compact and protected.

- Engine components: These parts are generally larger and more complex, often visible near the base of the machine.

- Fuel and air systems: These parts tend to have tubes, filters, and valves, located around the engine area.

- Safety features: Small, clearly marked sections that prevent accidents, often located on the sides or near the handle.

Referencing Guides for Accuracy

If you’re unsure about a component, a reference guide is invaluable. Diagrams or manuals provide a detailed look at where each piece fits within the structure. By cross-referencing your tool with these guides, you can ensure that you’ve correctly identified the parts and can proceed with repairs or maintenance.

Step-by-Step Guide to Husqvarna 445 Repair

Repairing your tool requires a systematic approach to ensure each component is correctly addressed. By following a structured method, you can confidently tackle any issues without causing further damage. This guide will walk you through each step, from diagnosing problems to fixing the most common issues found in outdoor equipment.

Step 1: Diagnosing the Problem

The first step in any repair process is identifying the issue. Start by performing a visual inspection of the tool to check for any obvious damage, such as cracks, loose parts, or worn-out components. Listen for unusual sounds and note any performance issues, such as reduced power or irregular operation.

- Look for visible cracks, leaks, or loose fittings.

- Check if the engine starts properly or if there are fuel flow issues.

- Listen for irregular sounds, which could indicate internal wear or misalignment.

Step 2: Disassembling the Equipment

Once the issue is identified, proceed to carefully disassemble the necessary sections. Keep track of each part as you remove them, organizing components to ensure easy reassembly later. Take extra care when handling delicate parts like the fuel system or engine components.

- Remove outer covers: Begin with the outer housing to access internal components.

- Disconnect fuel lines: Carefully detach the fuel lines and any other fluid connections to avoid spills.

- Label parts: Use labels or markers to keep track of each piece for easier reassembly.

Step 3: Replacing or Repairing the Damaged Component

After disassembling the tool, replace the faulty part with a new one or perform the necessary repairs. Ensure that the replacement part matches the specifications of the original component to avoid issues with fit and function. Follow the manufacturer’s guidelines for reinstallation and adjustments.

- Ensure all connections are tight and secure before reassembling.

- Check the alignment of internal components to prevent malfunction.

- Test the equipment before full reassembly to ensure proper function.

Step 4: Reassembly and Testing

Once the repair is complete, begin reassembling the tool. Ensure that each part is correctly placed and securely fastened. After reassembly, test the equipment thoroughly to confirm that the repair has resolved the issue and that it operates smoothly.

- Reassemble all parts in reverse order, ensuring each component fits snugly.

- Test the tool in a controlled environment to verify proper function.

- If needed, make final adjustments before regular use.