When maintaining a chainsaw, understanding its structure is key to ensuring optimal performance and longevity. Proper identification and knowledge of each element can help you with repairs and upgrades, saving both time and resources.

Exploring the internal setup of your machine can provide valuable insights into how different pieces work together. Familiarizing yourself with each section and its purpose will allow for more efficient troubleshooting and maintenance.

By delving into detailed schematics, you can confidently navigate through the various parts of the saw, ensuring you make informed decisions when replacing or repairing specific components. This guide will assist you in recognizing key areas and understanding their functions within the broader system.

Understanding the Chainsaw Components

Every chainsaw consists of multiple interconnected elements that each serve a specific purpose. Recognizing how these pieces work together is essential for maintaining the efficiency and functionality of the equipment. Knowing the key components allows you to troubleshoot issues, replace faulty parts, and make adjustments for improved performance.

Main Engine and Power Mechanism

The engine is the heart of the chainsaw, converting fuel into energy to drive the chain at high speeds. It is crucial to understand the components that make up the power system, including the fuel tank, carburetor, ignition system, and muffler. Each part contributes to the overall operation, with the carburetor regulating the air-fuel mixture and the ignition system ensuring proper combustion.

Cutting System and Chain Assembly

The cutting system consists of several important elements, including the chain, guide bar, and tensioning mechanisms. The chain is responsible for the cutting action, while the guide bar provides stability and control during operation. Regular inspection and maintenance of these components are vital for achieving clean cuts and preventing accidents.

Key Parts and Their Functions

Each component of a chainsaw plays a critical role in its overall performance. Understanding the function of these essential elements helps ensure the tool operates smoothly and safely. Knowing the specific purpose of each part allows users to perform targeted maintenance and make informed decisions when repairs are needed.

The engine serves as the driving force, converting fuel into mechanical power. It works in conjunction with the fuel system, which includes the fuel tank and carburetor, to maintain proper fuel flow and combustion. Meanwhile, the ignition system ensures reliable starting and consistent engine operation.

The cutting system, consisting of the chain and guide bar, is responsible for the actual cutting action. The chain moves rapidly along the guide bar, making precise cuts, while the tensioning mechanism keeps the chain properly aligned and taut. Regular monitoring of these parts is essential for maintaining cutting accuracy and preventing safety hazards.

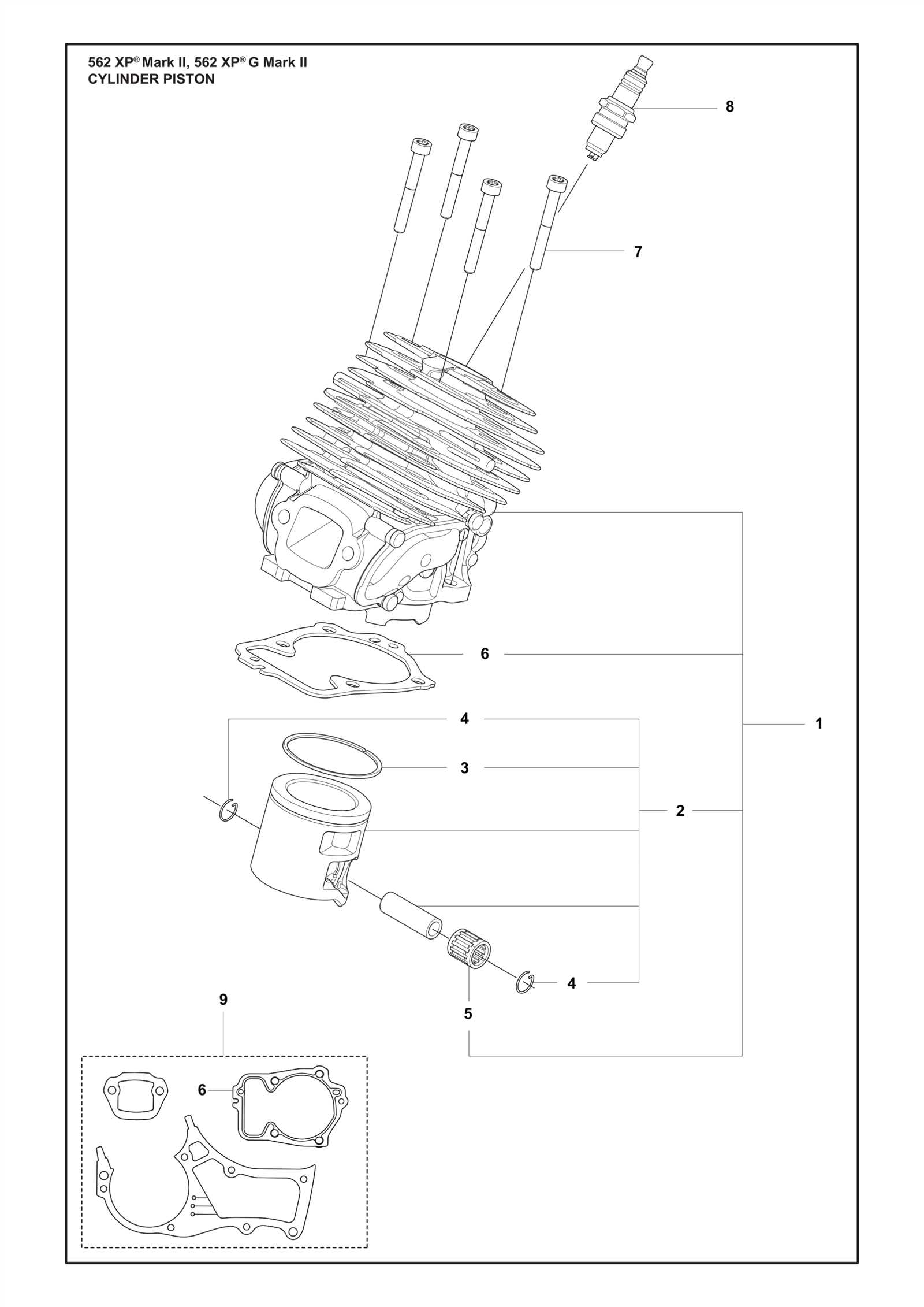

How to Read the Parts Diagram

Understanding the visual representation of a machine’s internal components is an essential skill for efficient maintenance and repair. A well-organized schematic provides a clear breakdown of each element and how they interact within the system. By familiarizing yourself with these visuals, you can easily identify and locate components for troubleshooting or replacement.

Identifying Components in the Diagram

The first step in reading a schematic is recognizing the symbols and labels used to represent various parts. Each component is typically numbered or marked, making it easier to reference the parts list for more detailed information. This helps to quickly find the exact piece you’re working with and understand its function within the larger system.

Interpreting Connections and Relationships

Once the individual parts are identified, focus on how they are connected. Lines or arrows often indicate how components interact with one another. Recognizing these relationships can guide you in diagnosing issues and understanding the flow of power or materials throughout the machine.